Cyclone generating device

A generation device and cyclone technology, which is applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve problems such as limiting the ability to transport liquids, corrosion, abrasion and even winding, and adverse effects on the suction efficiency of the air extraction device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

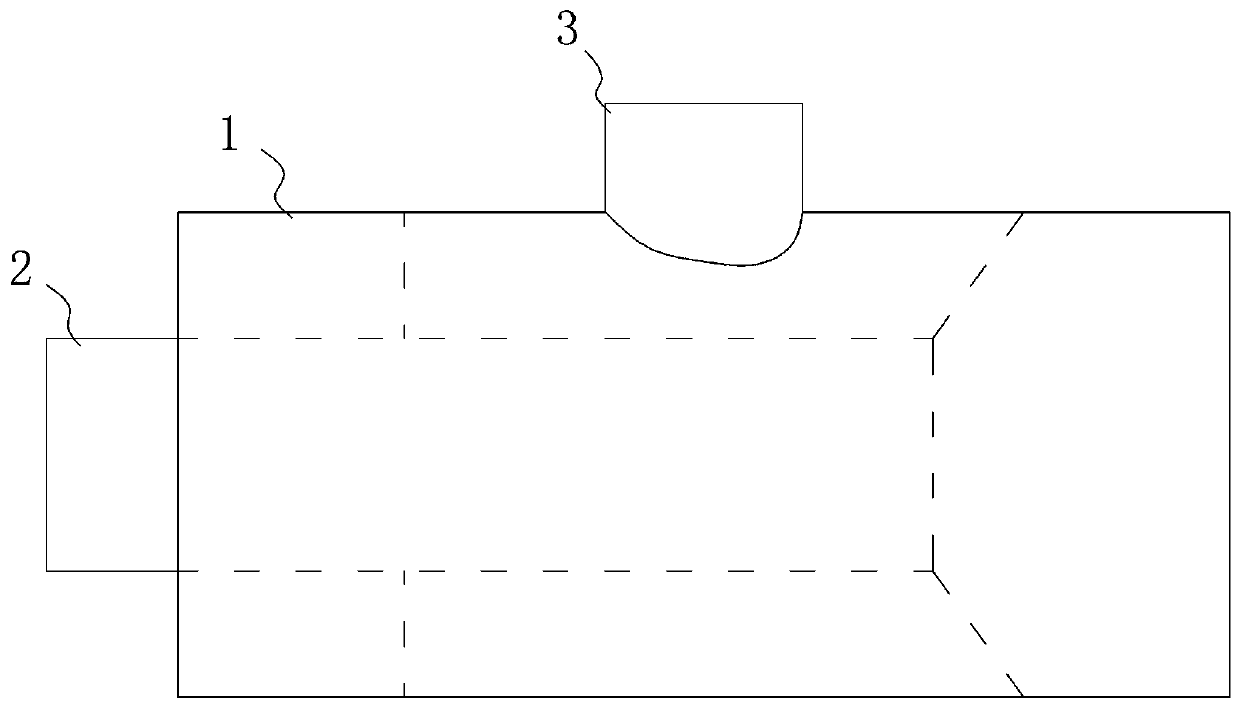

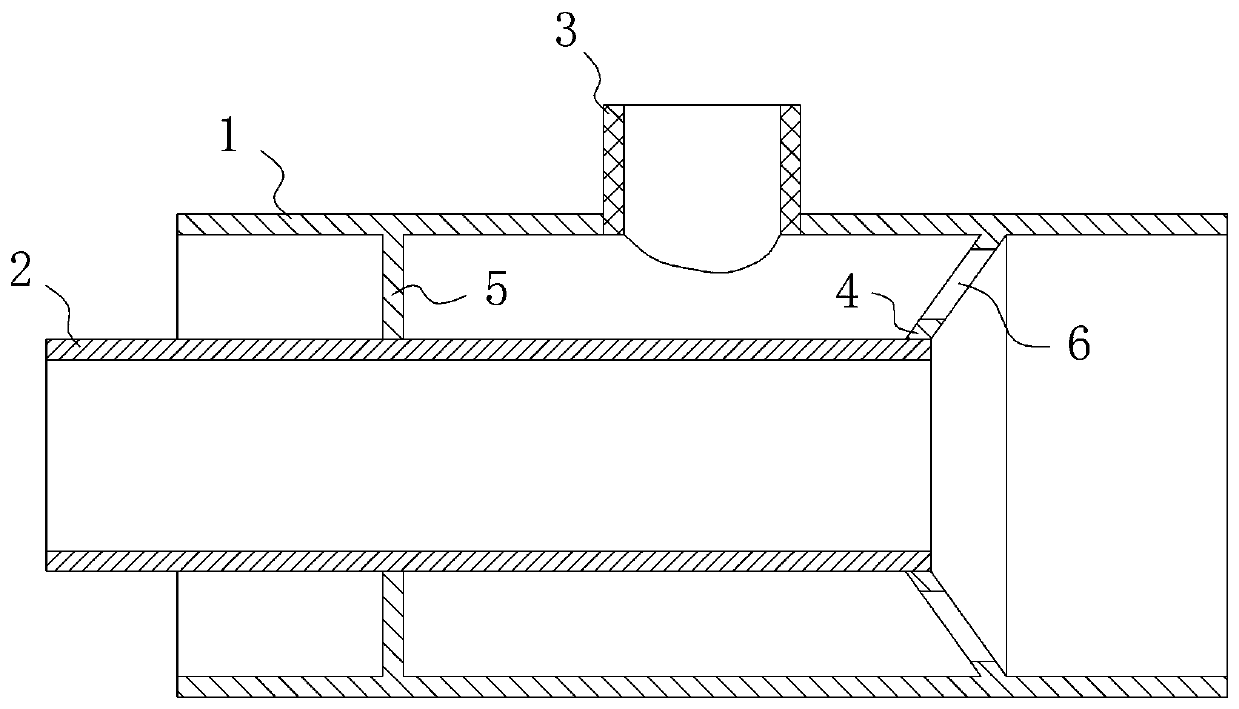

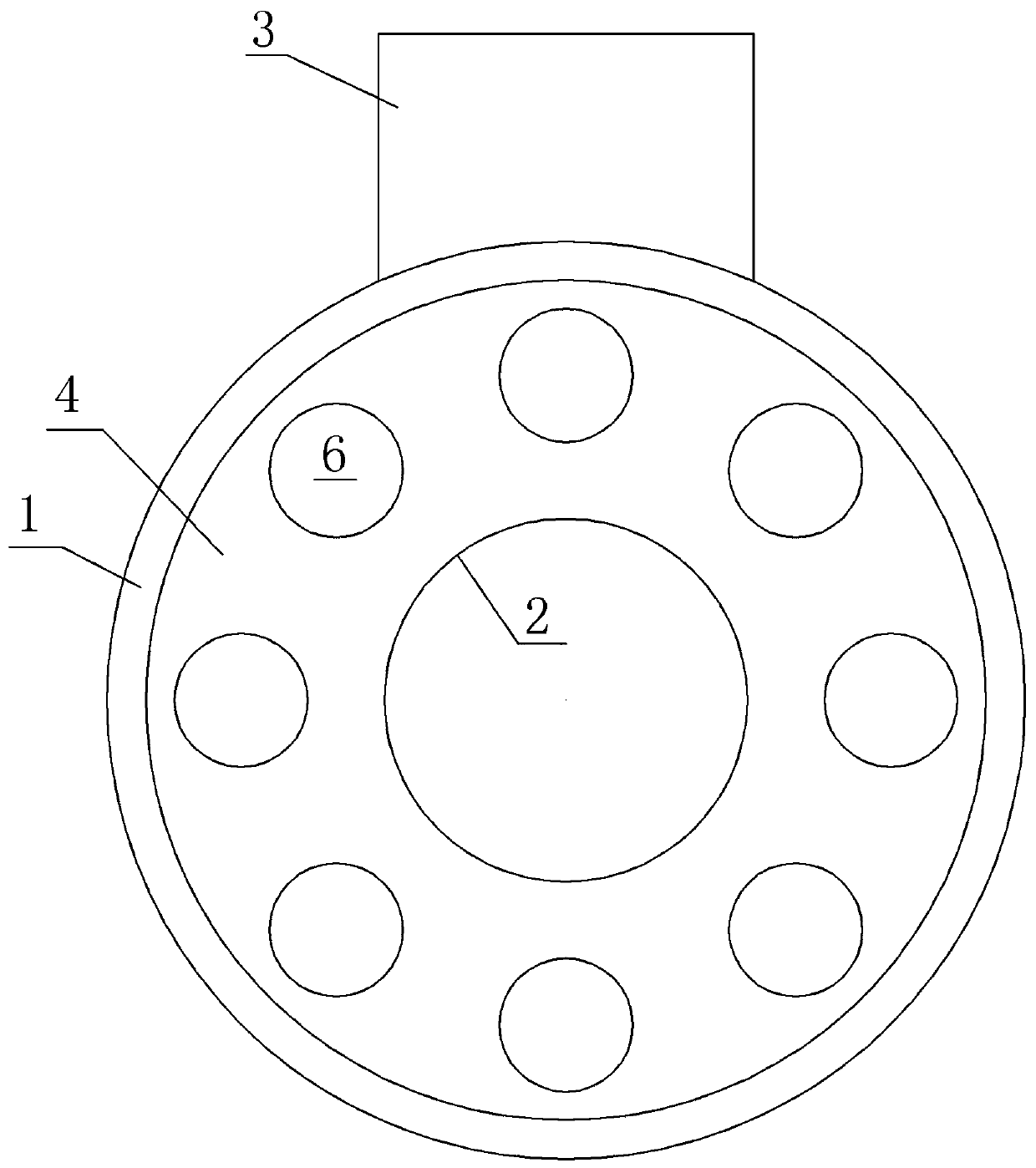

[0014] A cyclone generating device, including a wind energy pipe 1 and a material pipe 2 which are hollow inside and have different diameters. The outlet end of the material pipe is arranged in the wind energy pipe, and there is a gap between the outer wall of the material pipe and the inner wall of the wind energy pipe. The outer wall of the air intake tube is equipped with an air intake tube 3, which is hollow and connected to the wind energy tube; an annular wind energy ring 4 and a closed ring 5 are arranged between the inner wall of the wind energy tube and the outer wall of the material tube, and the inner circle of the wind energy ring is set in the material tube. The outlet end and the outer circle are located between the outlet end of the wind energy pipe and the air intake cylinder, the inner circle of the closed ring is placed on the material pipe and the outer circle is located between the inlet end of the wind energy pipe and the air intake cylinder, and the inner a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com