A cross-platform remote real-time motion tracking method for three fully mechanized mining machines

A motion tracking and cross-platform technology, applied in cutting machinery, mining equipment, earthwork drilling and mining, etc., can solve problems such as low visibility, no sense of immersion, and affecting the timeliness and accuracy of decision-making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

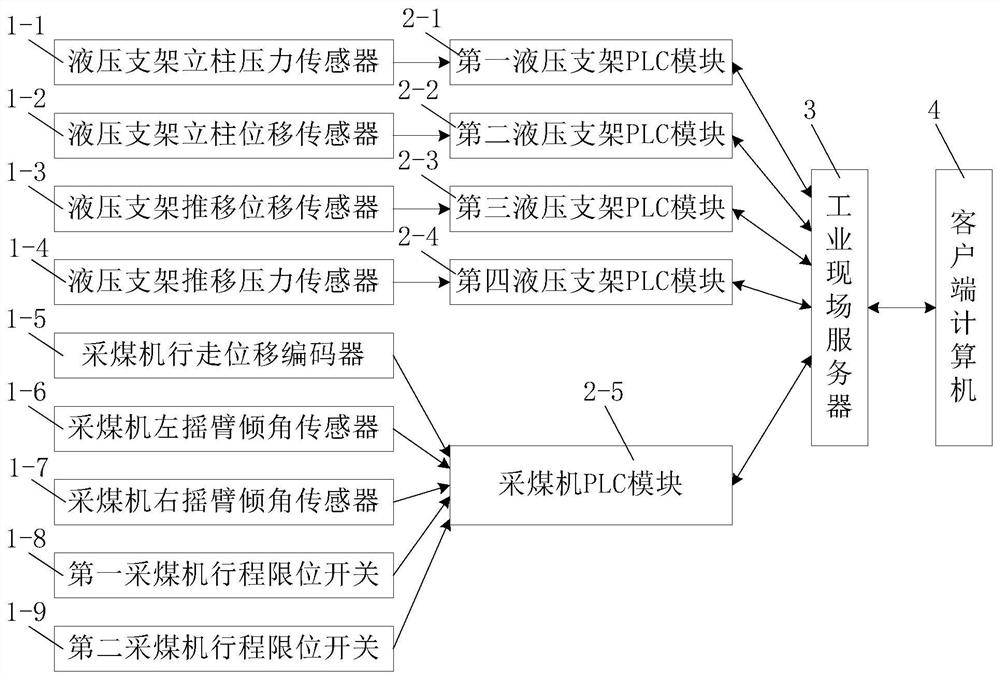

[0081] Such as figure 1 As shown, the cross-platform remote real-time motion tracking system of three fully mechanized mining machines of the present invention includes a sensor group, a PLC group, an industrial field server 3 and a client computer 4, and the sensor group includes a plurality of hydraulic support column pressure sensors 1-1 , multiple hydraulic support column displacement sensors 1-2, multiple hydraulic support push displacement sensors 1-3, multiple hydraulic support push pressure sensors 1-4, coal mining machine walking displacement encoder 1-5, coal mining machine left shake Arm inclination sensor 1-6, shearer right rocker arm inclination sensor 1-7, first shearer travel limit switch 1-8 and second shearer travel limit switch 1-9, the PLC group includes PLC module 2-1 of the first hydraulic support, PLC module 2-2 of the second hydraulic support, PLC module 2-3 of the third hydraulic support, PLC module 2-4 of the fourth hydraulic support and PLC module 2-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com