Novel pressure tank

A pressure tank, a new type of technology, applied in the field of air pump control and water pump, can solve the problems affecting the water pump control system, achieve the effect of improving technical performance, enhancing environmental adaptability, and reducing hidden dangers of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

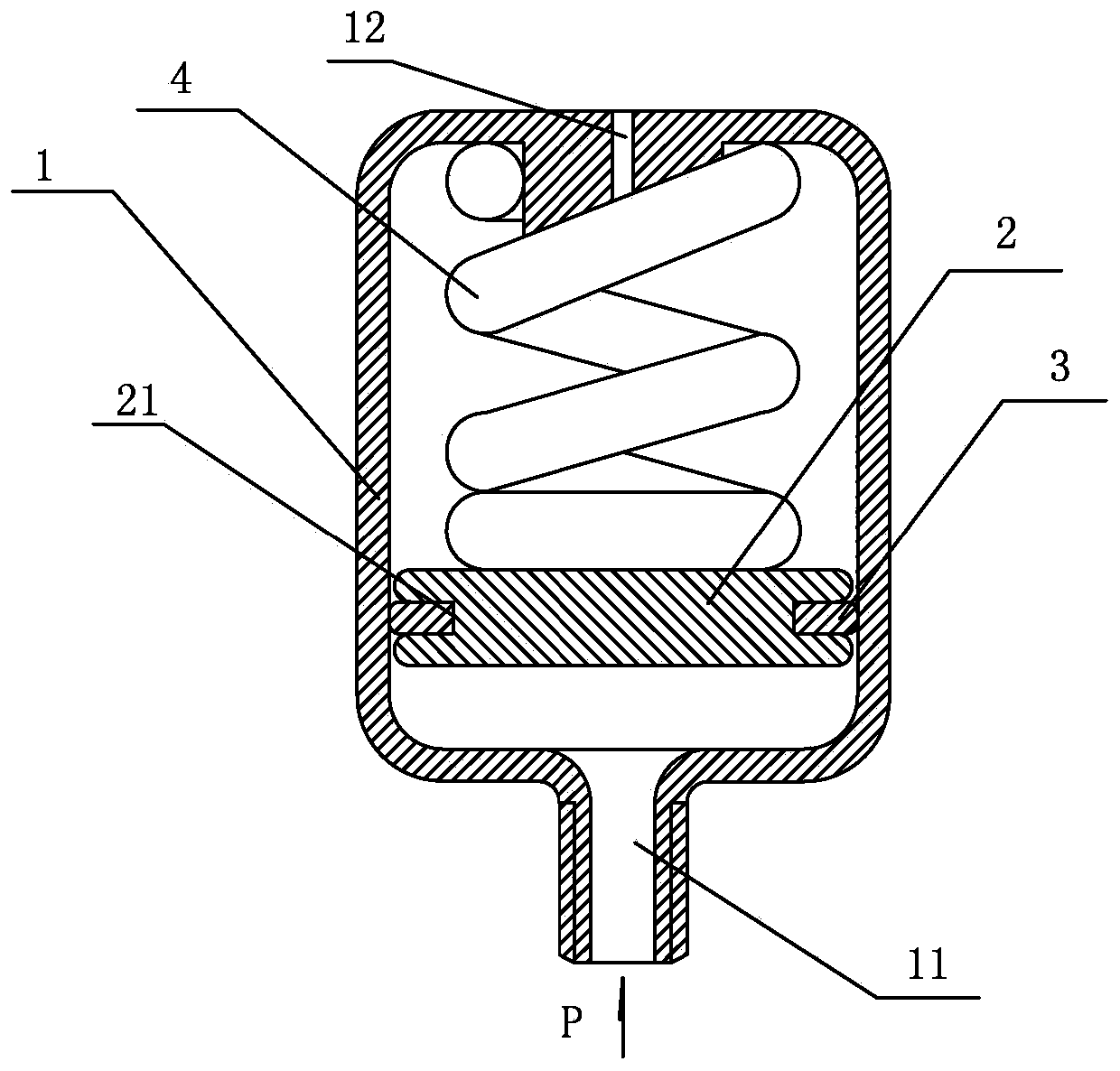

Embodiment 1

[0020] Example 1: Such as figure 1 As shown, a new type of pressure tank includes: inside the pressure tank 1, a pressure block 2 and a pressure spring 4 are arranged from bottom to top, the pressure block 2 is against the pressure spring 4, and the pressure spring 4 is in contact with the top of the inner cavity of the pressure tank 1 The outer edge of the pressure block 2 is provided with a groove 21, and an elastic spacer 3 composed of elastic soft materials (such as rubber, silica gel) is clamped in the groove 21 along the outer edge of the pressure block 2, integral with the pressure block 2, and with The inner wall of the inner cavity of the pressure tank 1 is tightly against each other, and when the pressure block 2 moves up and down along the inner cavity of the pressure tank 1, it acts as a radial seal and isolation.

[0021] The first situation: when there is an exhaust hole 12 on the top of the pressure tank 1, when the water flows into the pressure tank 1 from the wate...

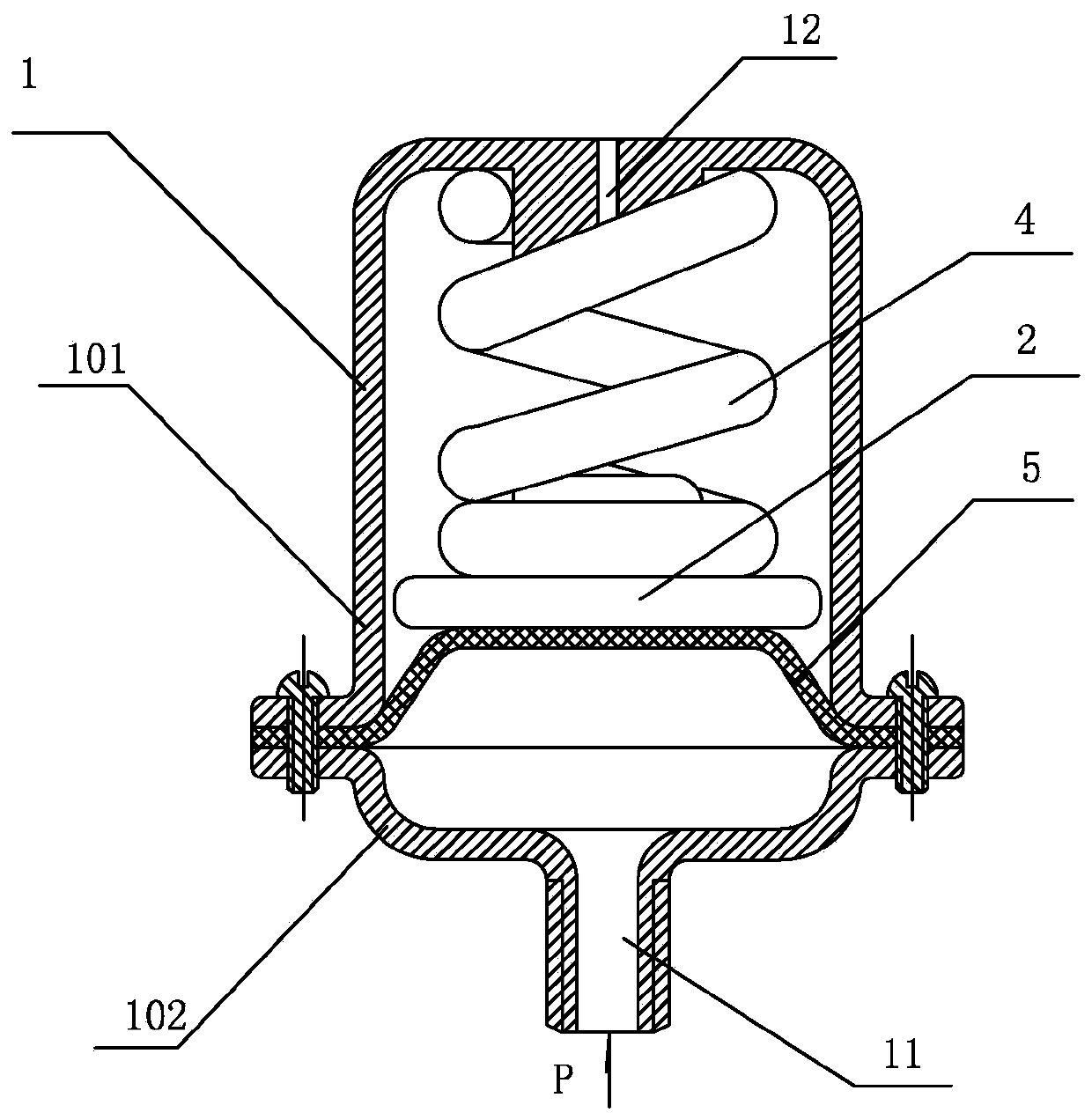

Embodiment 2

[0023] Example 2: Such as figure 2 As shown, a new type of pressure tank includes: inside the pressure tank 1, a waterproof isolation membrane 5, a pressure block 2 and a pressure spring 4 are arranged from bottom to top, wherein the waterproof isolation membrane 5 is against the pressure block 2, and the pressure block 2 and The pressure spring 4 abuts against the top of the inner cavity of the pressure tank 1. The pressure tank 1 is an assembled pressure tank. The entire pressure tank 1 is connected by the upper tank body 101 and the lower tank body 102 to form a whole. The tank body 102 is provided with a water inlet 11; the waterproof isolation membrane 5 is set in a concave shape to increase the expansion volume, and is composed of waterproof soft materials (such as rubber membrane, silicone membrane, plastic membrane, nylon membrane), and its outer edge is compressed It is connected between the upper tank body 101 and the lower tank body 102 to play a waterproof and seali...

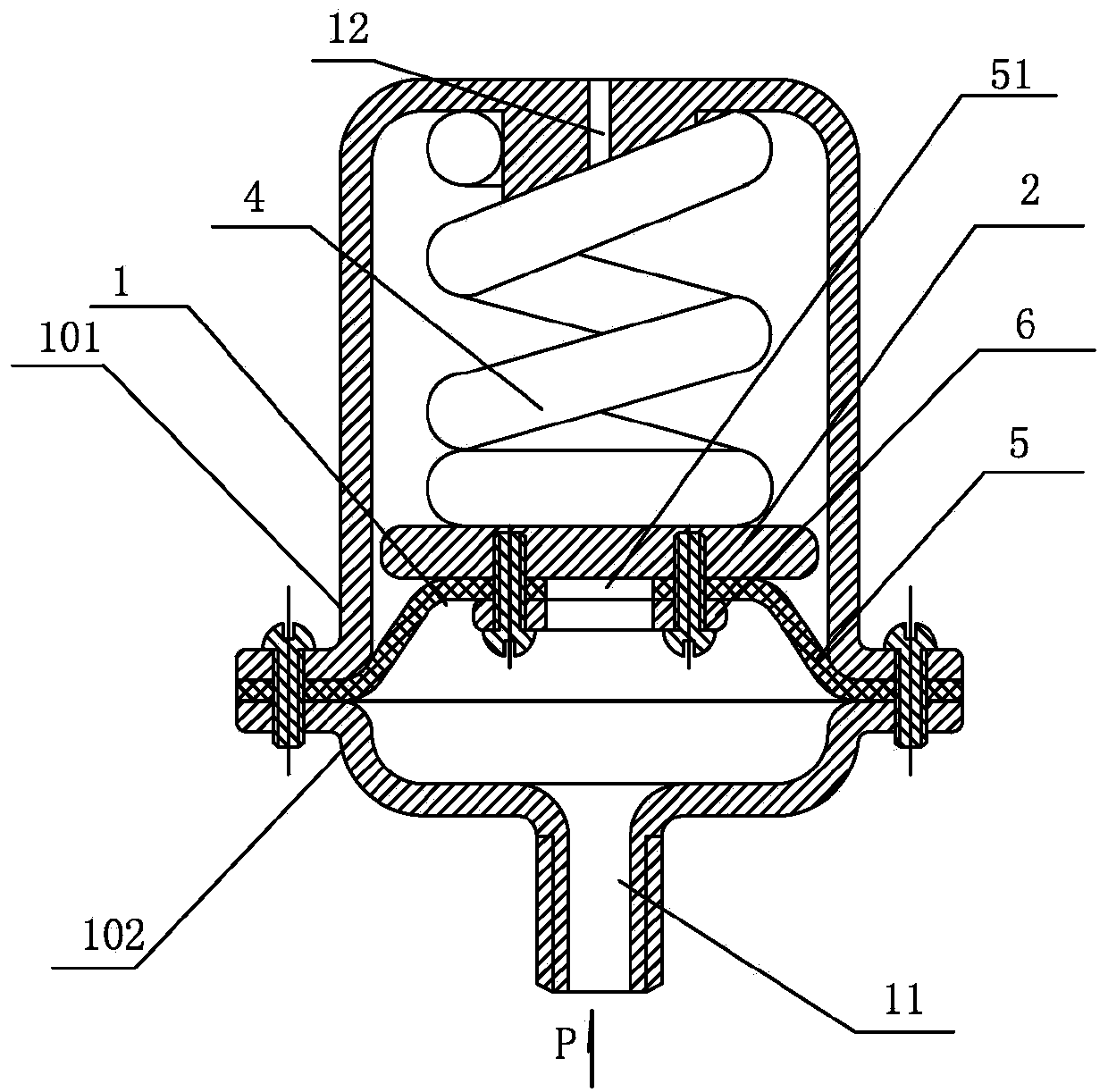

Embodiment 3

[0026] Example 3: Such as image 3 As shown, a new type of pressure tank includes: inside the pressure tank 1, a pressure ring 6, a waterproof isolation membrane 5, a pressure block 2 and a pressure spring 4 are arranged from bottom to top, wherein the waterproof isolation membrane 5 abuts the pressure block 2, The pressure block 2 is against the pressure spring 4, and the pressure spring 4 is against the top of the inner cavity of the pressure tank 1. The pressure tank 1 is an assembled pressure tank. The entire pressure tank 1 is connected by the upper tank body 101 and the lower tank body 102. The lower tank body 102 is provided with a water inlet 11; the waterproof isolation membrane 5 is set in a concave shape to increase the expansion volume, and a through hole 51 is provided in the middle. It is made of waterproof soft material (such as rubber film, silicone film, plastic film). , Nylon membrane), the outer periphery is crimped between the upper tank body 101 and the lowe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap