Method for extracting heat production time of a metal structure of a metal insulating layer

A metal structure, metal insulation technology, used in static memory, instruments, etc., can solve the problems of magnetic moment reversal of the storage layer, loss of information, easy breakage of the valence bond of the insulating layer, etc., to achieve accurate heat generation time constant and improve reliability. , the effect of high robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following detailed description, reference is made to the accompanying drawings which form a part hereof, and which show by way of illustration specific embodiments in which the invention may be practiced. It is to be understood that other embodiments may be utilized and structural or logical changes may be made without departing from the scope of the present invention. For example, features illustrated or described with respect to one embodiment can be used or combined with other embodiments to yield a still further embodiment. It is intended that the present invention include such modifications and variations. The embodiments are described using specific language which should not be construed as limiting the scope of the appending claims. The drawings are not drawn to scale and are for illustration purposes only.

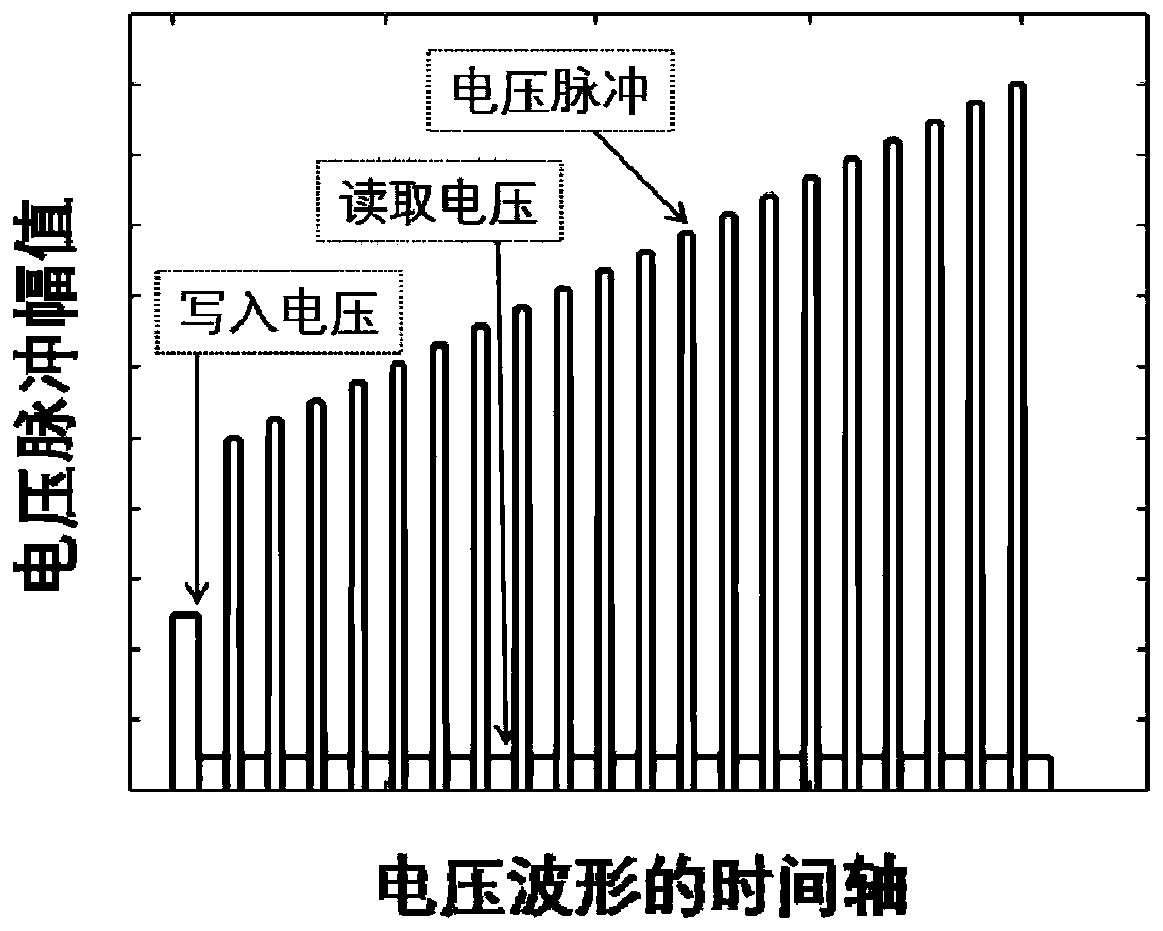

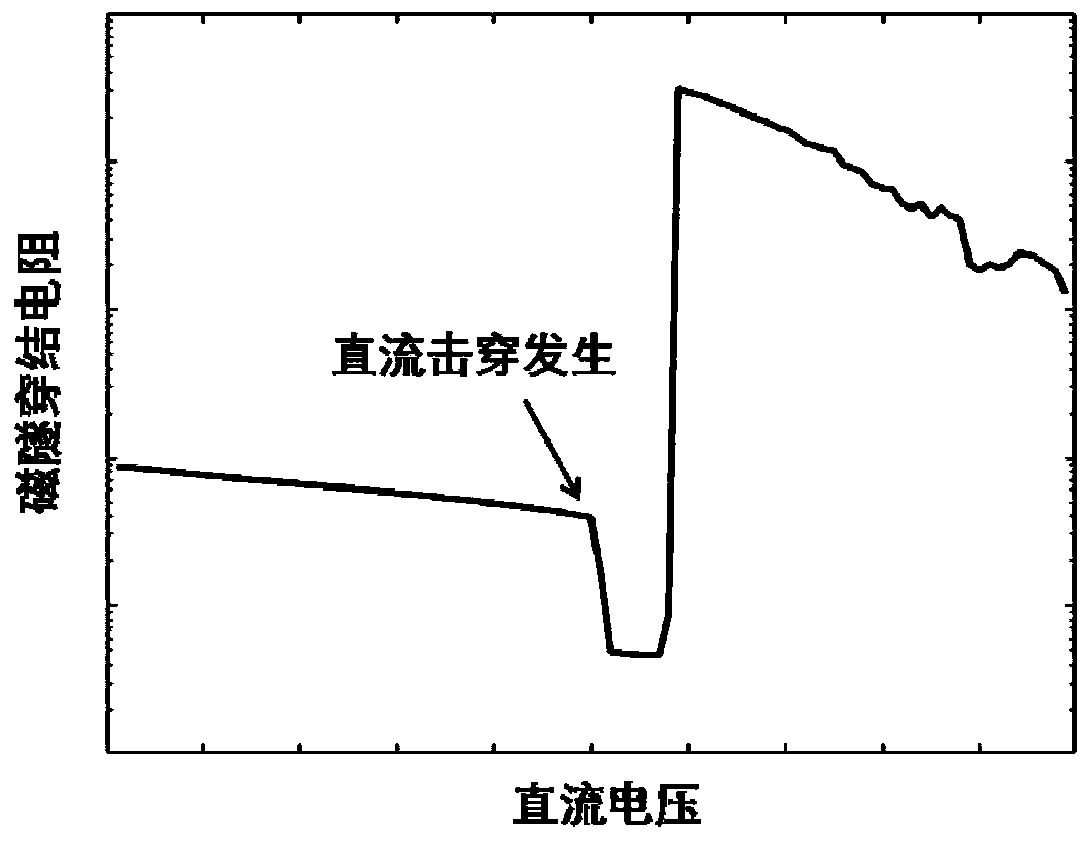

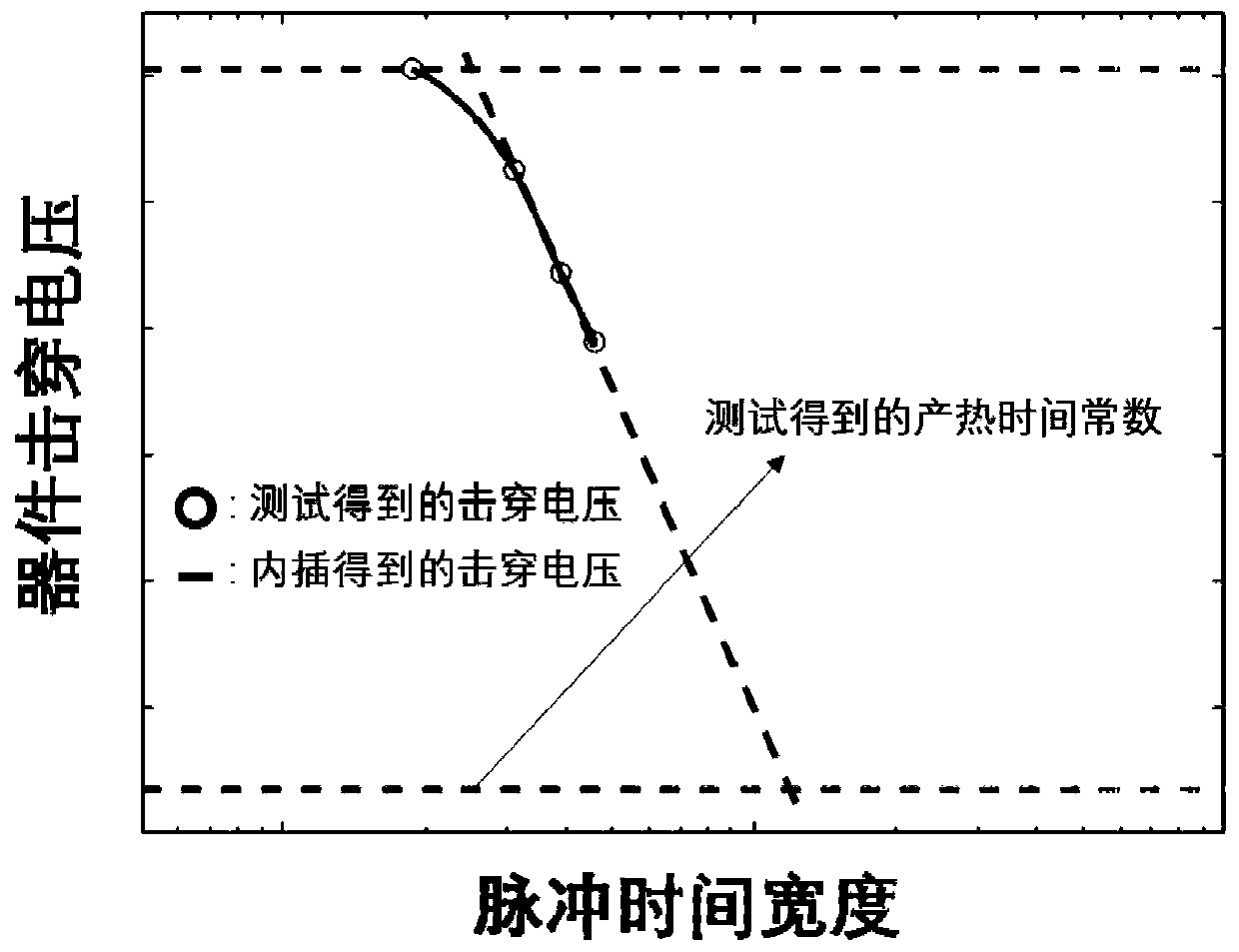

[0023] A method for extracting heat generation time of a metal structure of a metal insulating layer proposed by the present invention, said method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com