Nanoporous ultra-high molecular weight polyethylene membrane

An ultra-high molecular weight, nanoporous technology, applied in the field of nanoporous ultra-high molecular weight polyethylene film, can solve the problems of sacrificing battery performance and increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

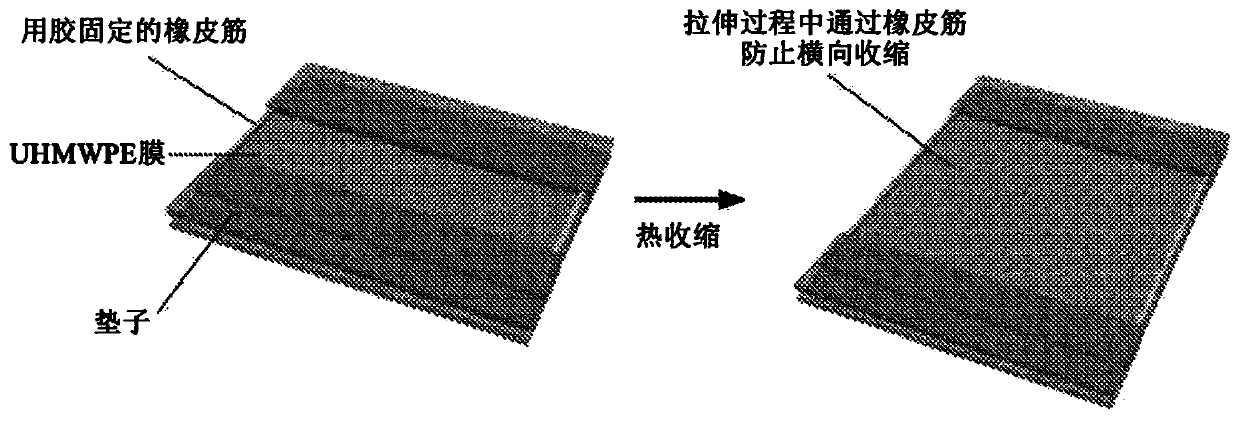

[0074] Embodiment 1. A method of preparing a biaxially oriented nanoporous ultrahigh molecular weight polyethylene (UHMWPE) film, the method comprising:

[0075] Blend petrolatum, UHMWPE and antioxidants;

[0076] Agitate petrolatum, UHMWPE and antioxidant to form a suspension;

[0077] feeding the suspension into an extruder to produce gel filaments;

[0078] compressing the gel filaments to form a gel film;

[0079] Stretch the gel film to a preset size;

[0080] exposing the stretched gel film to an annealing temperature; and

[0081] Petrolatum was extracted from the stretched gel film.

Embodiment approach 2

[0082] Embodiment 2. The method of embodiment 1, wherein petrolatum, ultra high molecular weight polyethylene (UHMWPE) and antioxidant are stirred at a temperature of 120°C.

Embodiment approach 3

[0083] Embodiment 3. The method of any one of embodiments 1 to 2, wherein the petrolatum comprises petrolatum, white petrolatum, or a semi-solid mixture of hydrocarbons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com