Steel bar non-drawing processing method based on building information modeling (BIM)

A processing method and steel bar technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor cost, high loss rate of raw materials, and difficult control of processing accuracy, so as to improve construction efficiency, save production cost, The effect of reducing the loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

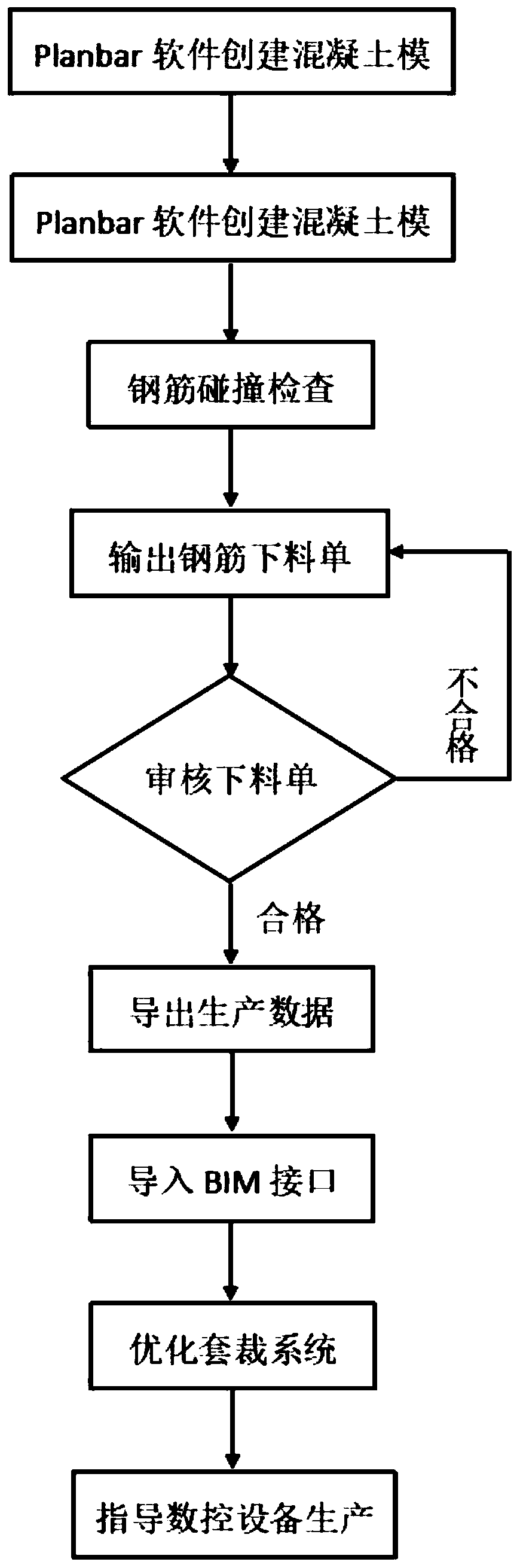

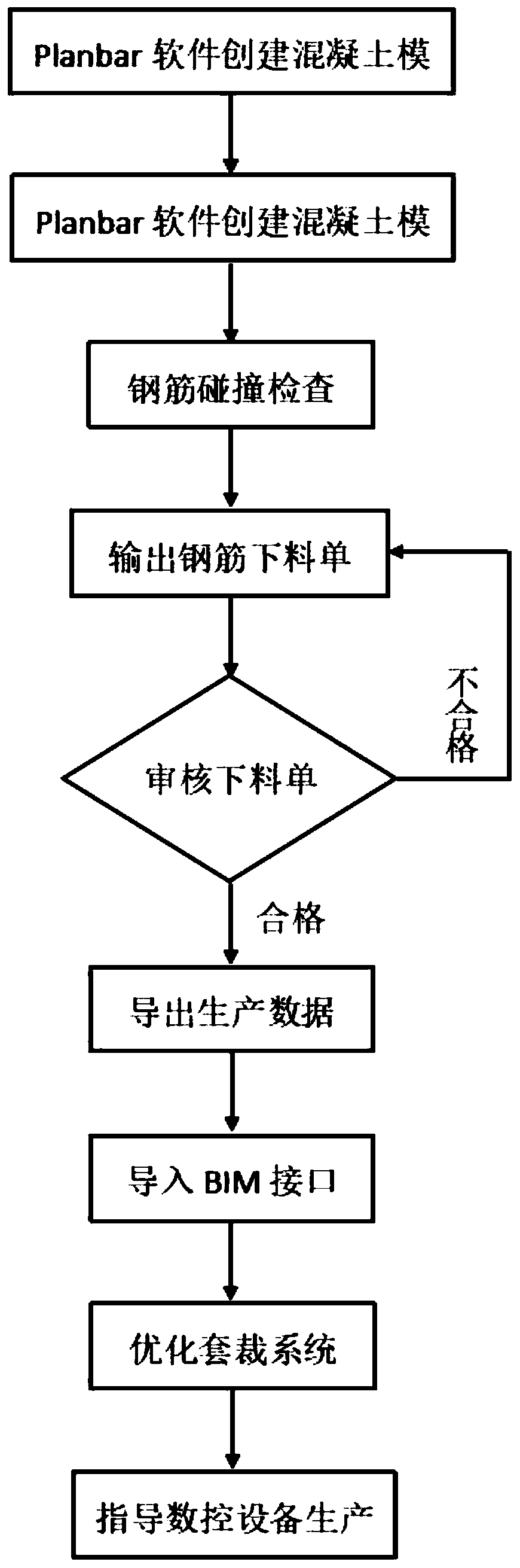

[0025] In the present invention, the BIM software adopts Planbar software to create concrete component models, create steel bar models, check collisions, output steel bar blanking lists, and output BVBS data.

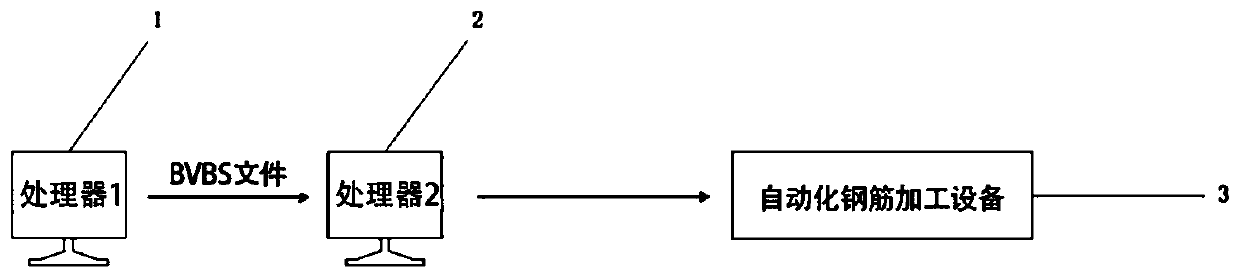

[0026] Such as figure 1 and figure 2 , the non-mapping processing method based on BIM steel provided by the present invention, the specific implementation steps are as follows:

[0027] Step 1. Create a concrete model

[0028] The technician divides and numbers the concrete model according to the construction unit and construction sequence, installs the Planbar software in the processor 11, applies the Planbar software, and establishes the concrete component model for each division position according to the construction drawings; when modeling, consider the convenience of steel bar modeling, first Create part of the model or draw auxiliary lines;

[0029] Step 2. Create a reinforcement model

[0030] Use Planbar software to create a steel bar model in the created c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com