Liquid return device, starch spraying and stewing equipment and starch liquefying device and method

A technology of jet cooking and starch liquefaction, applied in the field of starch deep processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

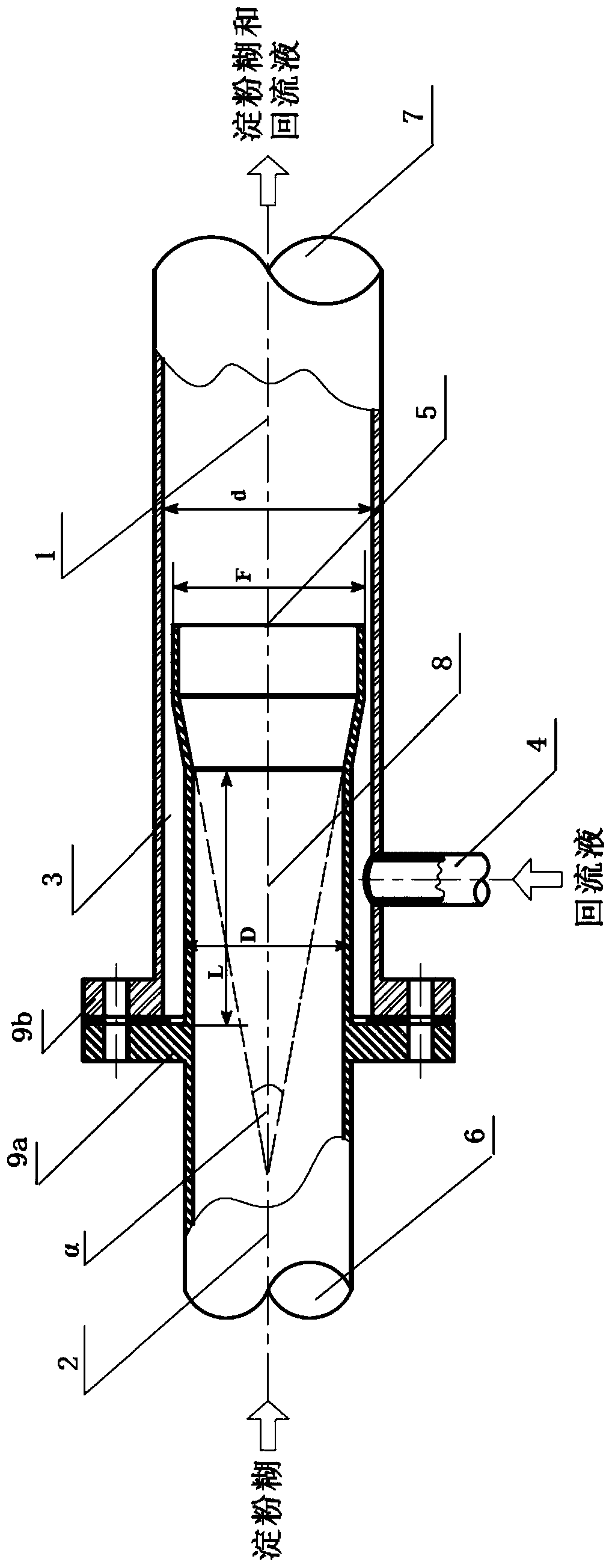

[0051] included in figure 1 The starch sugar production device of the spray cooking equipment of the liquid return device provided by the present invention is shown to carry out high-concentration starch milk to produce starch sugar.

[0052] Among them, the outer diameter of the inlet of the liquid return device (equal to the outer diameter D of the inner tube) is 3.2 cm, and the inner diameter (d) of the outlet of the liquid return device is 4 cm; the length (L) of the extension section of the inner tube inside the outer tube is 5 cm , the extension section is connected to the expansion section, the cone angle α of the expansion section is 30°, the outer diameter (F) of the inner tube outlet is 3.85cm, and the inner diameter is 3.5cm. One liquid return pipe, with an inner diameter of 1.5 cm, is vertically arranged with the outer pipe 1 .

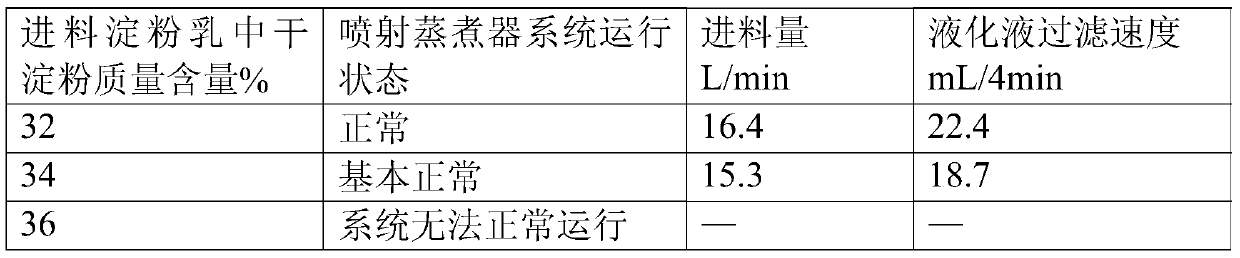

[0053] On the starch milk jet cooking liquefaction device comprising the liquid return device provided by the present invention with a p...

Embodiment 2

[0060] The outer diameter of the inlet of the liquid return device (equal to the outer diameter D of the inner tube) is 3.2 cm, and the inner diameter (d) of the outlet of the liquid return device is 4 cm; the length (L) of the extension section of the inner tube inside the outer tube is 5 cm. The inlet section is connected to the expansion section, the cone angle α of the expansion section is 45°, the outer diameter (F) of the outlet of the inner tube is 3.9cm, and the inner diameter is 3.55cm. One liquid return pipe, with an inner diameter of 1.5 cm, is vertically arranged with the outer pipe 1 .

[0061] On the starch milk jet cooking liquefaction device with a processing capacity of 1000L / h that includes the liquid return device provided by the present invention, the commercial dry starch and fresh process water are prepared to have dry starch contents of 38 mass%, 42 mass% and 44 mass% respectively. Mass% starch milk with three concentrations, and add a sodium hydroxide s...

Embodiment 3

[0068] The outer diameter of the inlet of the liquid return device (equal to the outer diameter D of the inner tube) is 3.2 cm, and the inner diameter (d) of the outlet of the liquid return device is 4 cm; the length (L) of the extension section of the inner tube inside the outer tube is 5 cm. The inlet section is connected to the expansion section, the cone angle α of the expansion section is 60°, the outer diameter (F) of the inner tube outlet is 3.93cm, and the inner diameter is 3.6cm. One liquid return pipe, with an inner diameter of 1 cm, is vertically arranged with the outer pipe 1 .

[0069]On the starch milk jet cooking liquefaction device with a processing capacity of 1000L / h that includes the liquid return device provided by the present invention, the commercial dry starch and fresh process water are prepared so that the dry starch content is 40 mass %, 43 mass % and 45 mass % respectively. Mass% starch milk with three concentrations, and add a sodium hydroxide solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com