Braider special for sewage treatment carbon fiber ecological aquatic plants

A technology for sewage treatment and carbon fiber, applied in the field of weaving machines, can solve the problems of carbon fiber being difficult to diverge and easy to block, and achieve the effects of saving labor, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

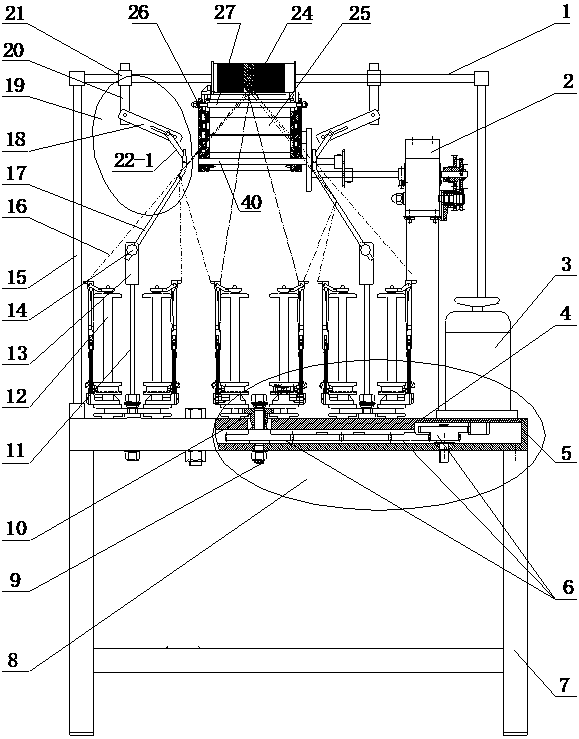

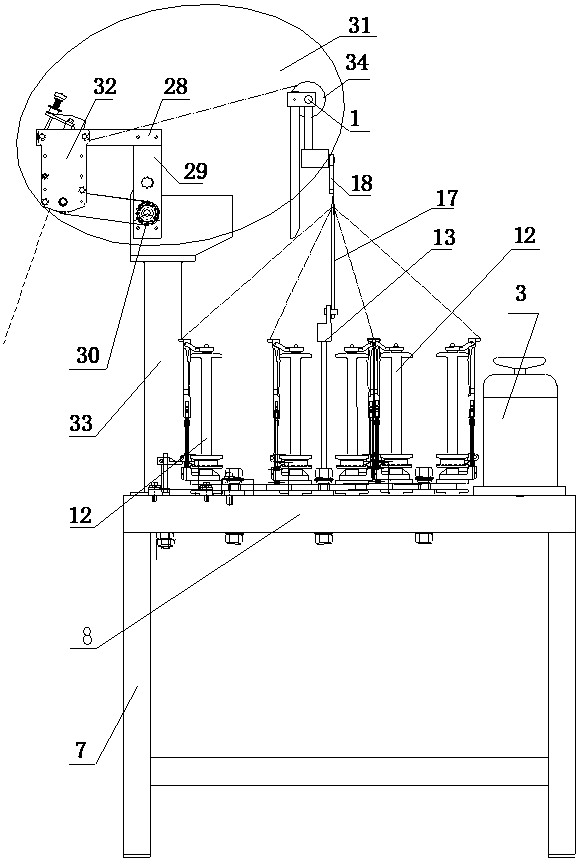

[0034] Embodiment 1: the special weaving machine for aquatic plants comprises: a weaving transmission device 8, a cutting device and a take-up device; the weaving transmission device 8 comprises: a frame 7, a lower plate 5, an upper plate 4, a spindle 12, a dial 10, The dial shaft 9, transmission gear 6 and motor 3; the lower disc 5 is connected with the frame 7, the upper disc 4 is connected with the lower disc 5, the dial 10 passes through the upper disc 4 and is set on the dial shaft 9, and the spindle 12 is stuck on the On the dial 10, a transmission gear 6 is provided between the upper disc 4 and the lower disc 5, and the motor 3 meshes with the transmission gear 6;

[0035] The weaving transmission device is installed on the frame 7, and there is a wire take-up device above the weaving transmission device, and the wire take-up device is installed on one side of the frame through a wire take-up bracket; 1 is connected with a cutting device.

[0036] The cutting device is...

Embodiment 2

[0044] Embodiment 2: The described cutting device is a rotary cutting device.

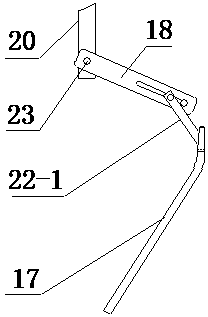

[0045] The rotary cutting device includes: adjusting shaft seat 21, blade, blade motor seat 35, blade motor 36, transmission belt 37, picker 17; adjusting shaft seat 21 is installed on the wheel shaft 1, and blade motor seat 35 is installed on the adjusting shaft On the seat 21; the blade motor 36 and the blade are installed on the blade motor seat 35, the blade motor 36 drives the blade to rotate through the transmission belt 37, the blade is a round blade 22-2, and the cutting edge of the round blade is positioned at the top of the picker 17 At the notch, the circular blade 22-2 cooperates with the picker 17, and the rotating circular blade 22-2 cuts off the fiber thread picked out by the picker 17 of the braiding machine.

[0046] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com