Stepped transmission with mechanical uninterrupted power

A transmission and power technology, applied in the direction of mechanical equipment, vehicle gearboxes, transmission components, etc., to improve work efficiency, eliminate impact force, and avoid potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

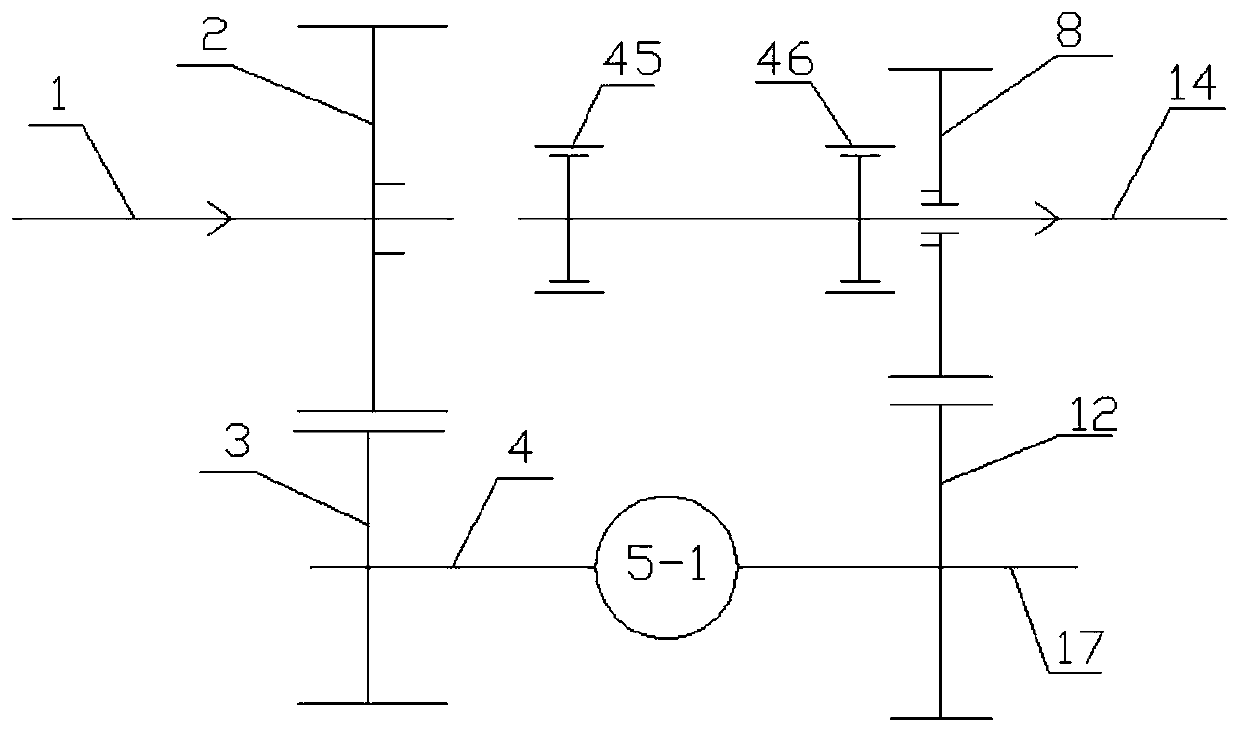

[0041] The mechanical uninterrupted power stepped transmission disclosed in the present invention includes a frictionless transmission speed governor, a first shaft, a second shaft, an intermediate shaft, an odd-numbered drive gear, an odd-numbered driven gear, and an even-numbered drive gear. , Even number gear driven gear, odd number gear combination sleeve and even number gear combination sleeve;

[0042] The frictionless transmission speed governor includes: a speed governor motor or a hydraulic motor, governor input teeth and governor output teeth, the input teeth of the governor mesh with the driving teeth of the first shaft, the The output gear of the governor is connected with the even-numbered gear or odd-numbered gear through the intermediate shaft;

[0043] The frictionless transmission speed governor changes the speed of the speed-regulating motor or the hydraulic motor to adjust the speed of the output gear of the governor to complete the switching of even-numbered gea...

Embodiment 2

[0045] The second embodiment is the first differential speed governor:

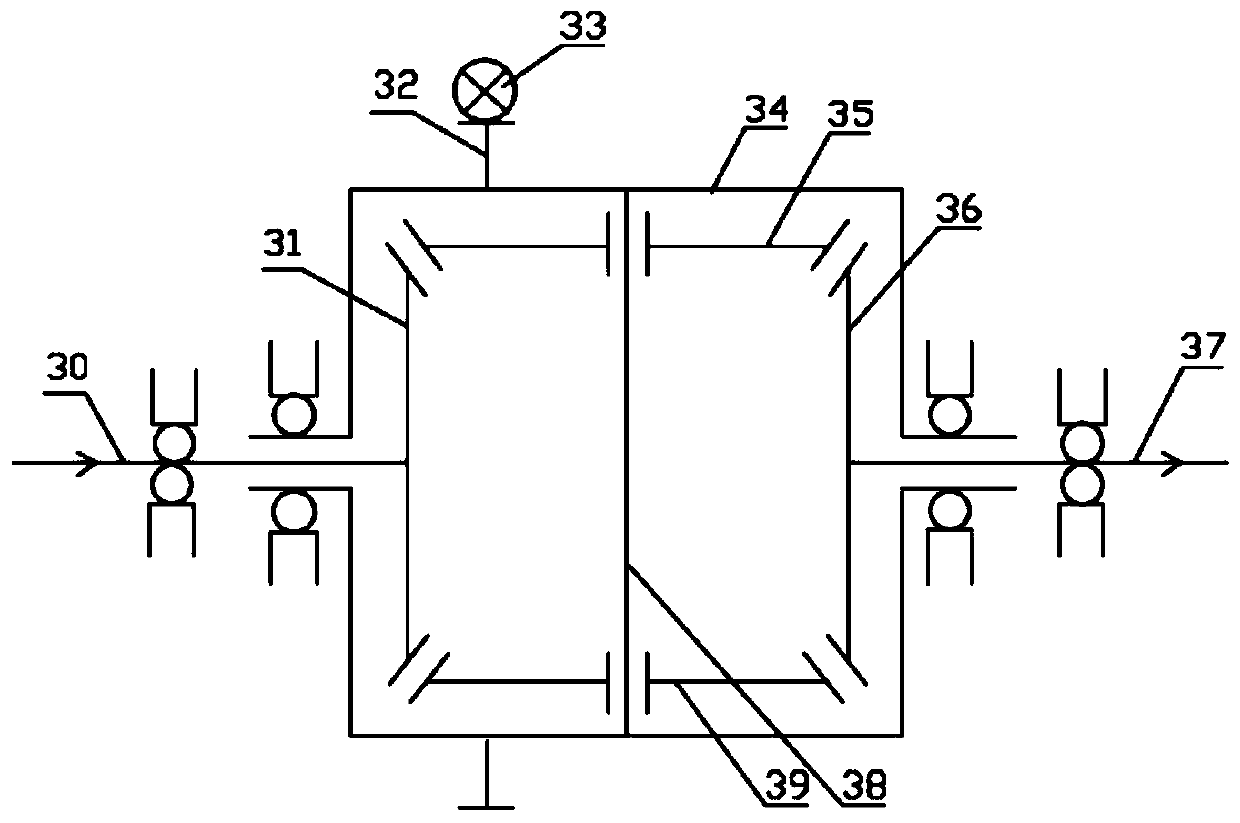

[0046] Such as figure 1 As shown, the frictionless transmission speed governor of this embodiment includes:

[0047] Differential case, speed regulating motor or hydraulic motor, worm gear, planetary gear, planetary gear shaft, governor input gear and governor output gear;

[0048] The planetary gear looper is connected to the planetary gear shaft, the planetary gear shaft is fixed on the differential housing, the governor input gear and the governor output gear are connected to the differential housing through the looper, the differential housing The worm gear is fixed on the differential housing through a bearing fixedly connected to the transmission case, the speed regulating motor or hydraulic motor is fixed on the transmission case, and the worm gear is engaged with the worm gear through a worm.

[0049] The differential speed governor includes a speed regulating motor or hydraulic motor, a differential hous...

Embodiment 3

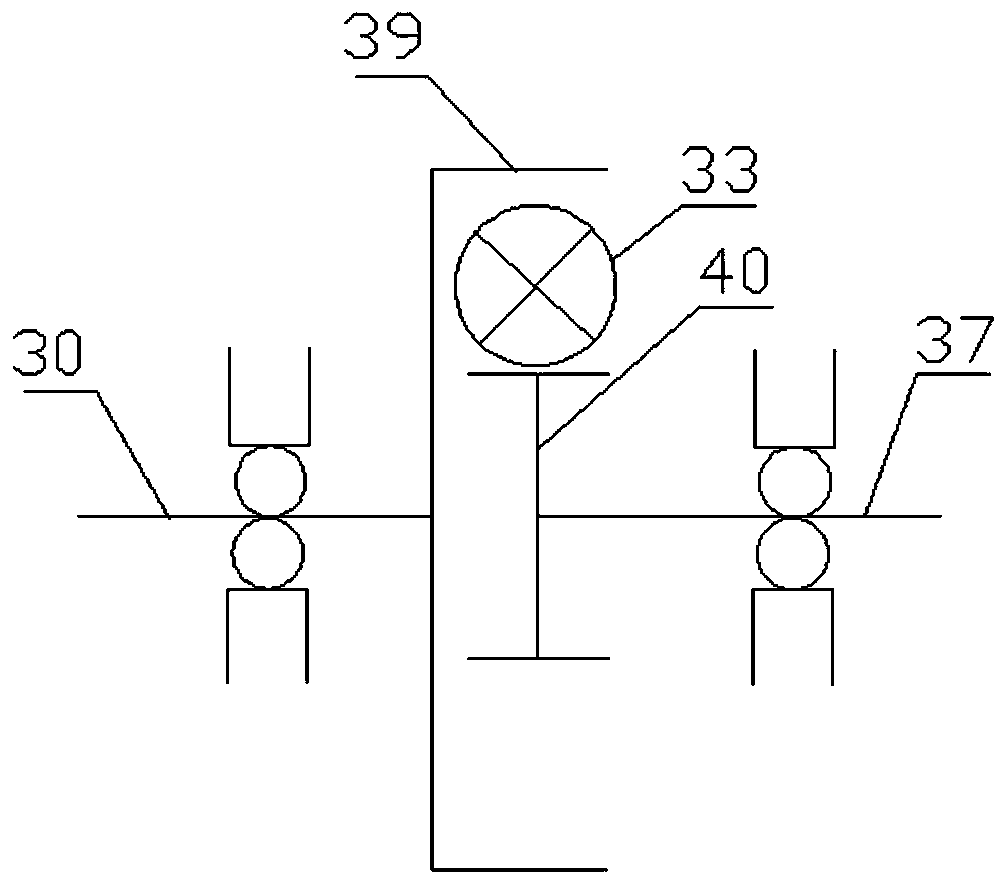

[0050] The third embodiment is the second type of speed governor:

[0051] Such as figure 2 As shown, the frictionless transmission governor includes: governor motor or hydraulic motor, governor input wheel, governor output worm gear, governor output shaft and governor input shaft;

[0052] The speed regulating motor or the hydraulic motor is fixedly connected with the speed regulating input wheel of the speed governor, and meshes with the worm wheel of the speed governor through a worm.

[0053] The speed regulating motor or the hydraulic motor is fixedly connected with the speed regulating input wheel of the speed governor, and meshes with the worm and the worm wheel under self-locking conditions. When the motor is not rotating, the speed of the governor input shaft and the governor output shaft are the same. When the motor is rotating, there is a difference in speed between the speed governor input shaft and the speed governor output shaft. This difference can realize the gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com