Method for measuring ammonia content in paper packaging materials for water-based ink printing

A paper packaging material and detection method technology, applied in the field of tobacco, can solve the problems of cumbersome operation, complicated instruments, easy to be interfered, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Determination of ammonia in paper packaging materials printed with water-based ink:

[0039] (1) Preparation of standard solution:

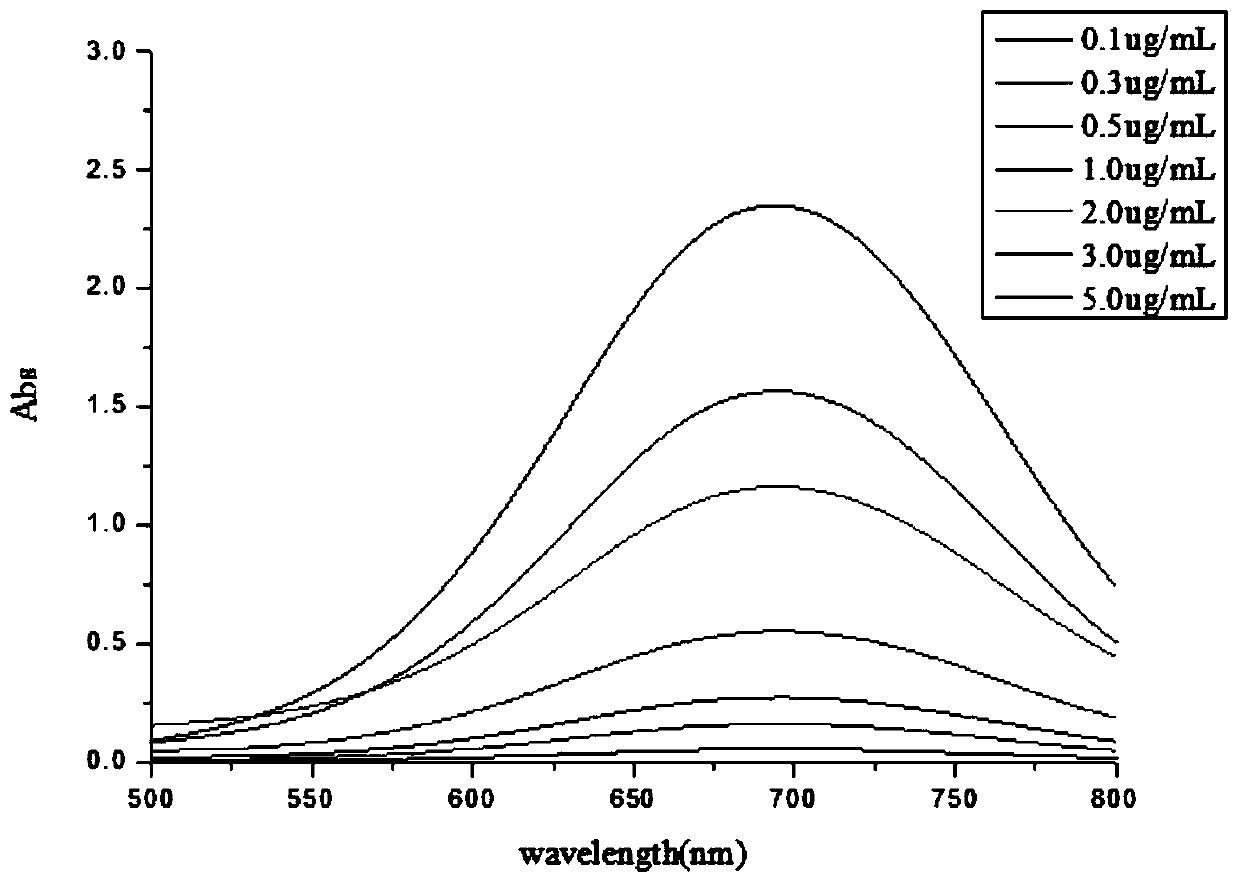

[0040] Using ammonium chloride as the standard substance and hydrochloric acid solution with a concentration of 0.01mol / L as the solvent, prepare standard working solutions with NH4+ concentrations of 0.1, 0.3, 0.5, 1.0, 2.0, 3.0, and 5.0ug / mL.

[0041] HCl aqueous solution: take 0.975ml concentrated hydrochloric acid, dilute it to 1000ml, and prepare a hydrochloric acid solution with a concentration of 0.01mol / L;

[0042] NaOH aqueous solution: weigh 8 g of NaOH solid, add water to dilute to 100 mL, and obtain a NaOH aqueous solution with a concentration of 2 mol / L;

[0043] Salicylic acid solution: take 5g of salicylic acid and 5g of sodium citrate dihydrate, add about 25ml of water, add 27.5ml of NaOH (c(NaOH)=2mol / L), and dilute with water to 100mL to obtain a concentration of 50g / L Salicylic acid solution;

[0044] Sodium nitrosofe...

Embodiment 2

[0052] (1) Preparation of standard solution

[0053] With ammonium chloride as the standard substance and hydrochloric acid solution with a concentration of 0.01mol / L as the solvent, a standard stock solution with a concentration of NH4+ of 100ug / mL was prepared.

[0054] HCl aqueous solution: take 0.975ml concentrated hydrochloric acid, dilute it to 1000ml, and prepare a hydrochloric acid solution with a concentration of 0.01mol / L;

[0055] NaOH aqueous solution: weigh 8 g of NaOH solid, add water to dilute to 100 mL, and obtain a NaOH aqueous solution with a concentration of 2 mol / L;

[0056] Salicylic acid solution: take 5g of salicylic acid and 5g of sodium citrate dihydrate, add about 25ml of water, add 27.5ml of NaOH (c(NaOH)=2mol / L), and dilute with water to 100mL to obtain a concentration of 50g / L Salicylic acid solution;

[0057] Sodium nitrosoferricyanide: Take 0.5g and dissolve it in 100mL of water to obtain a sodium nitrosoferricyanide solution with a concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap