Positive and negative electrode electrolyte and preparation method thereof, and application of positive and negative electrode electrolyte in A14-model flow battery

A cathode electrolyte and anode electrolyte technology, applied in the field of electrochemistry, can solve the problems of low cost, low energy density of flow batteries, hindering wide commercial application, etc., and achieve the effect of low cost and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

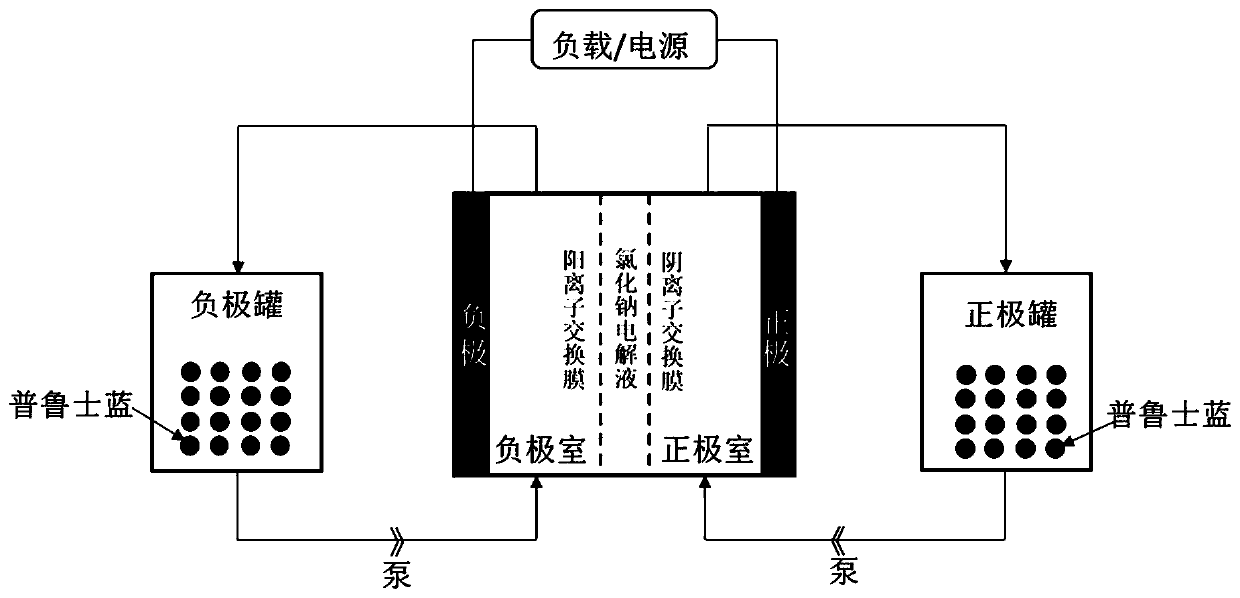

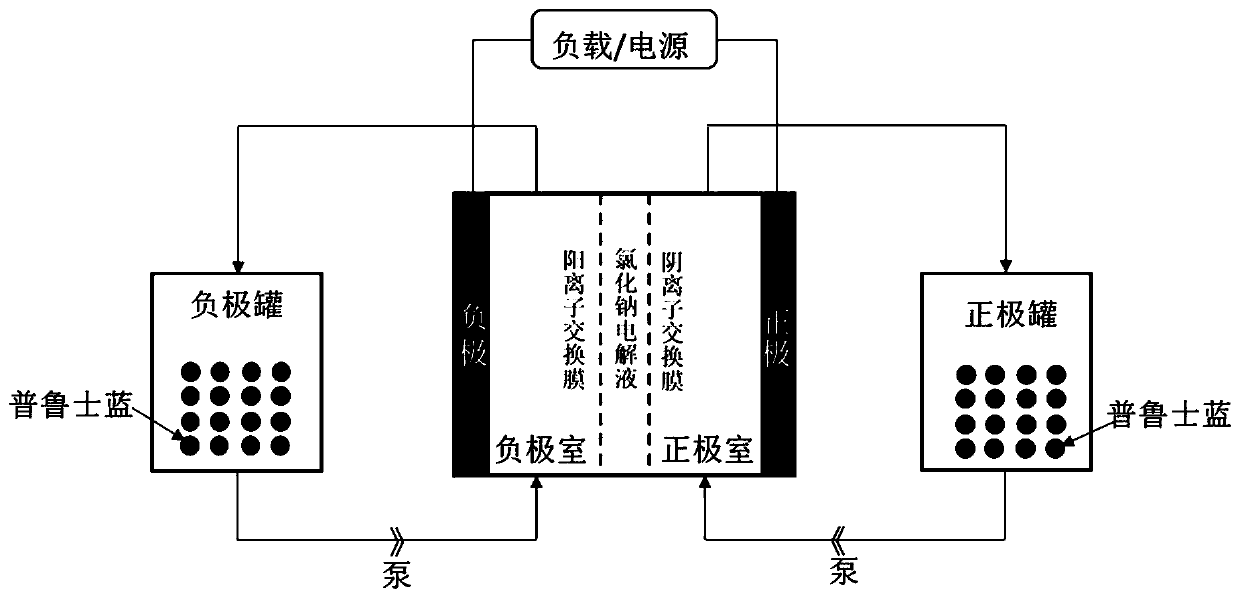

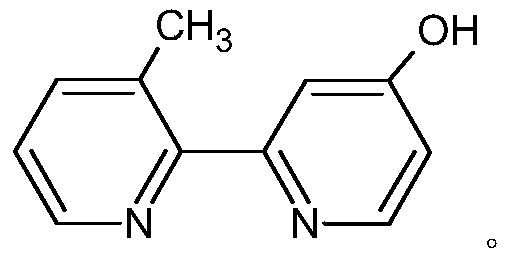

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: prepare 100mL 0.02M K 3 Fe(CN) 6 +0.02M C 6 h 12 N 4 / HCl+0.02M NaCl electrolyte

[0039] First weigh 0.002mol K 3 Fe(CN) 6 , put in a 250mL beaker, add 50mL of water, stir well; then add 0.002mol C 6 h 12 N 4 , 0.002mol / HCl, fully stirred; then sequentially add 0.002molNaCl, add water until the solution is 100mL, and fully stir to obtain the desired prepared electrolyte.

Embodiment 2

[0040] Embodiment 2: prepare 100mL 0.4M K 3 Fe(CN) 6 +0.8M C 6 h 12 N 4 / HCl+0.8M NaCl electrolyte

[0041] First weigh 0.04mol K 3 Fe(CN) 6 , put in a 250mL beaker, add 50mL of water, stir well; then add 0.08mol C 6 h 12 N 4 , 0.08mol / HCl, fully stirred; then sequentially add 0.08molNaCl, add water until the solution is 100mL, and fully stir to obtain the desired prepared electrolyte.

Embodiment 3

[0042] Embodiment 3: preparation 100mL 0.8M K 3 Fe(CN) 6 +1.6M C 6 h 12 N 4 / HCl+1.6M NaCl electrolyte

[0043] First weigh 0.08mol K 3 Fe(CN) 6 , put in a 250mL beaker, add 50mL of water, stir well; then add 0.16mol C 6 h 12 N 4 , 0.16mol / HCl, fully stirred; then sequentially add 0.16molNaCl, add water until the solution is 100mL, and fully stir to obtain the desired prepared electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com