Secondary integration device of high tension switchgear

A high-voltage switchgear and circuit module technology, applied in the field of secondary integrated devices and high-voltage switchgear secondary integrated devices, can solve the problems of difficulty in overall quality inspection, lack of secondary functional electrical appliances, long length, etc. Simple structure and the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

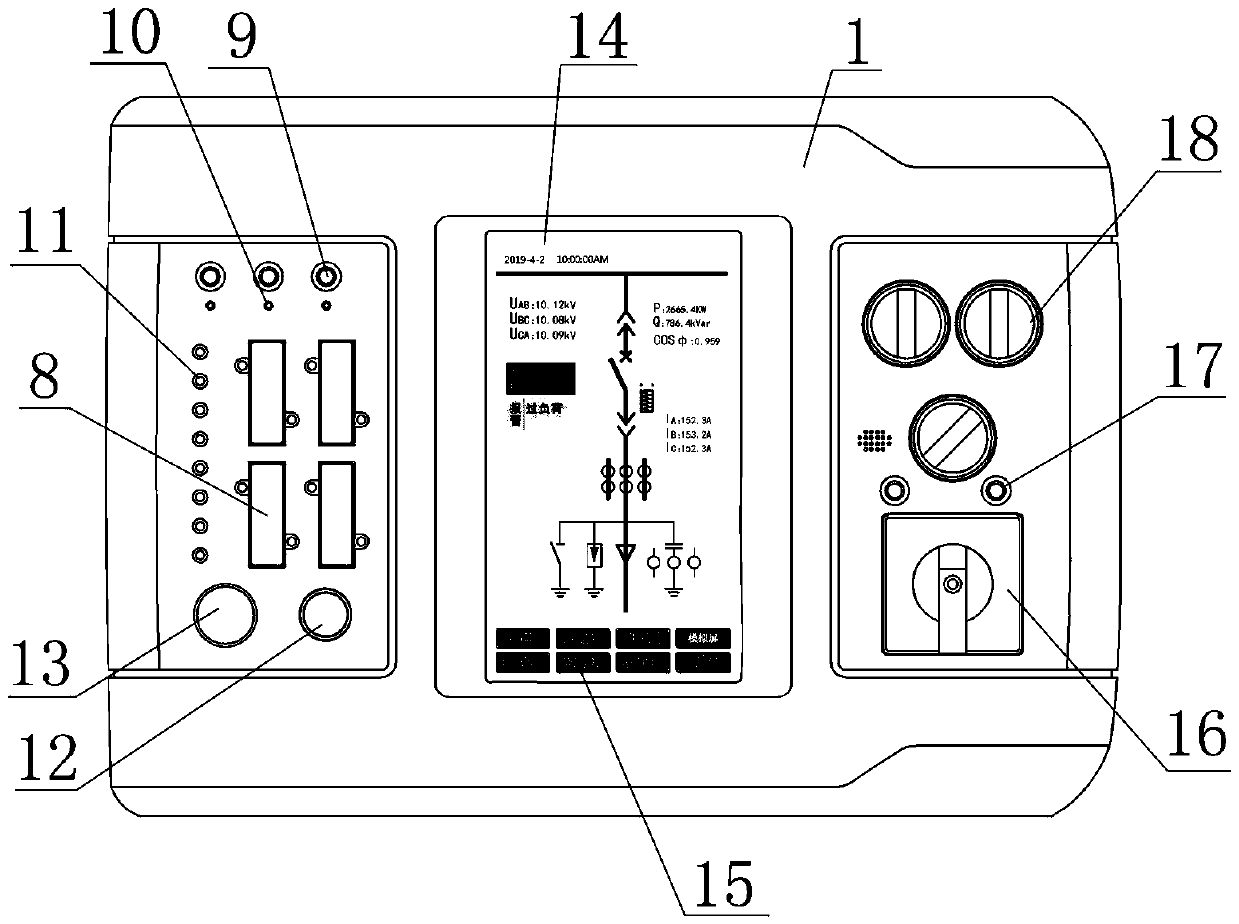

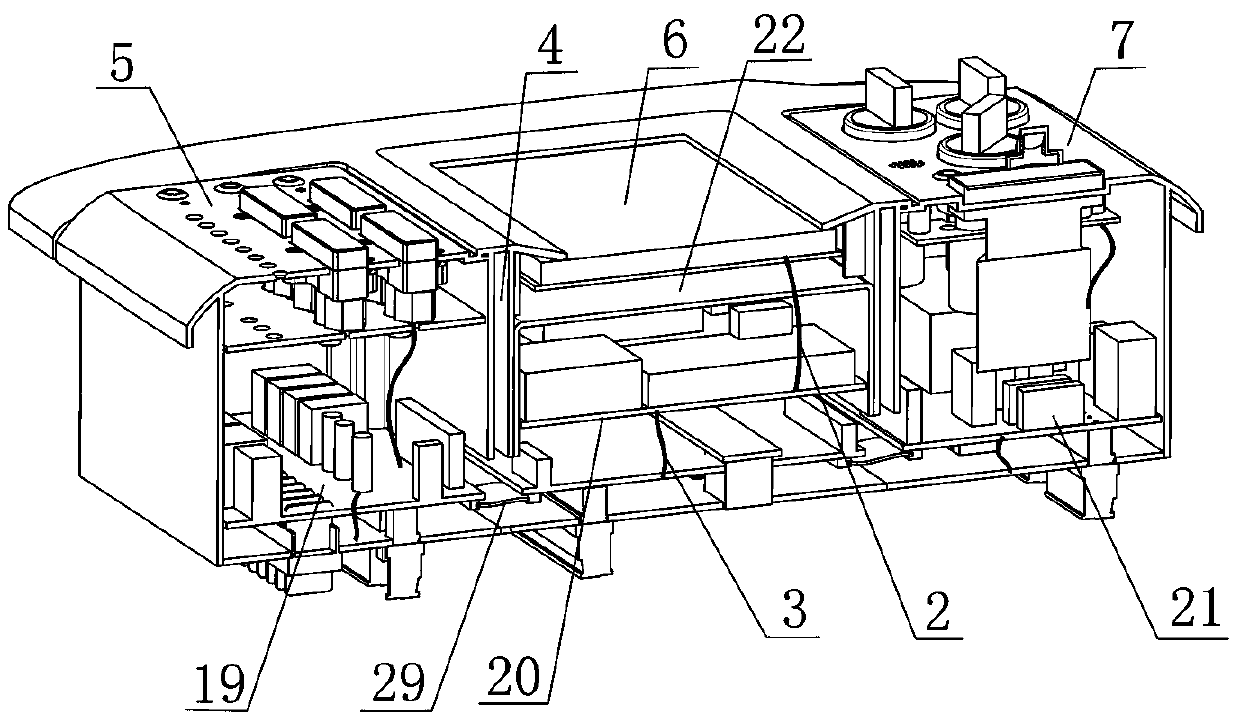

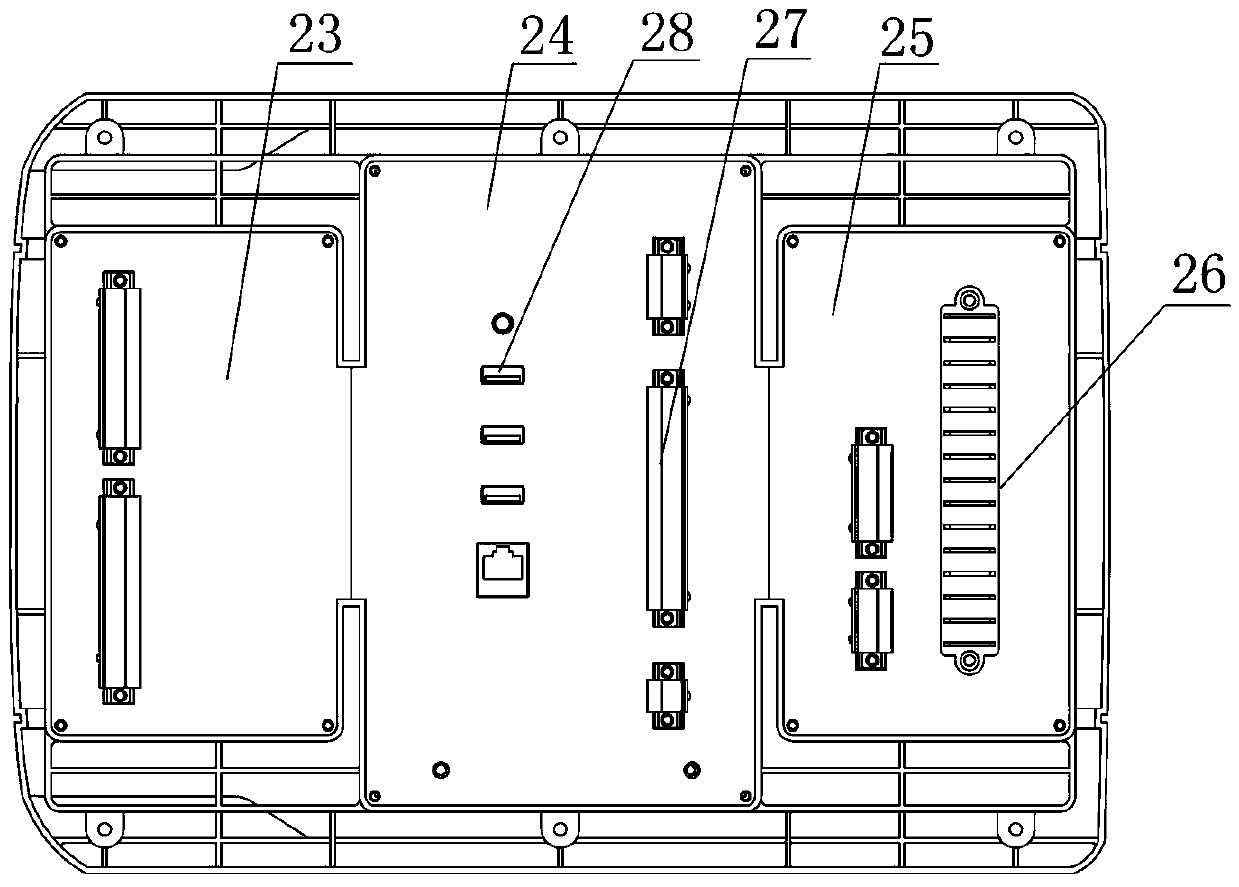

[0027] Such as figure 1 , 2 , 3, a high-voltage switchgear secondary comprehensive device of the present invention includes a housing 1, a front panel circuit module, a body circuit module and a rear cover circuit module, and the front panel circuit module is arranged on the front panel of the housing 1 Above, the body circuit module is set in the housing cavity 1, and the rear cover circuit module is set on the rear cover of the shell 1, wherein the front panel circuit module and the body circuit module are connected through the front cable 2, and the body circuit module It is connected with the rear cover circuit module through the rear machine cable 3, the front panel circuit module contains visual display and tactile manipulation devices, the body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com