Pulse vacuum arc plasma propeller with segmented microporous insulating anode

A technology of pulsed vacuum and plasma, applied in the direction of plasma, plasma utilization, thrust reverser, etc., can solve the problem of increased plasma generation, achieve the effect of increasing generation and propagation speed, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

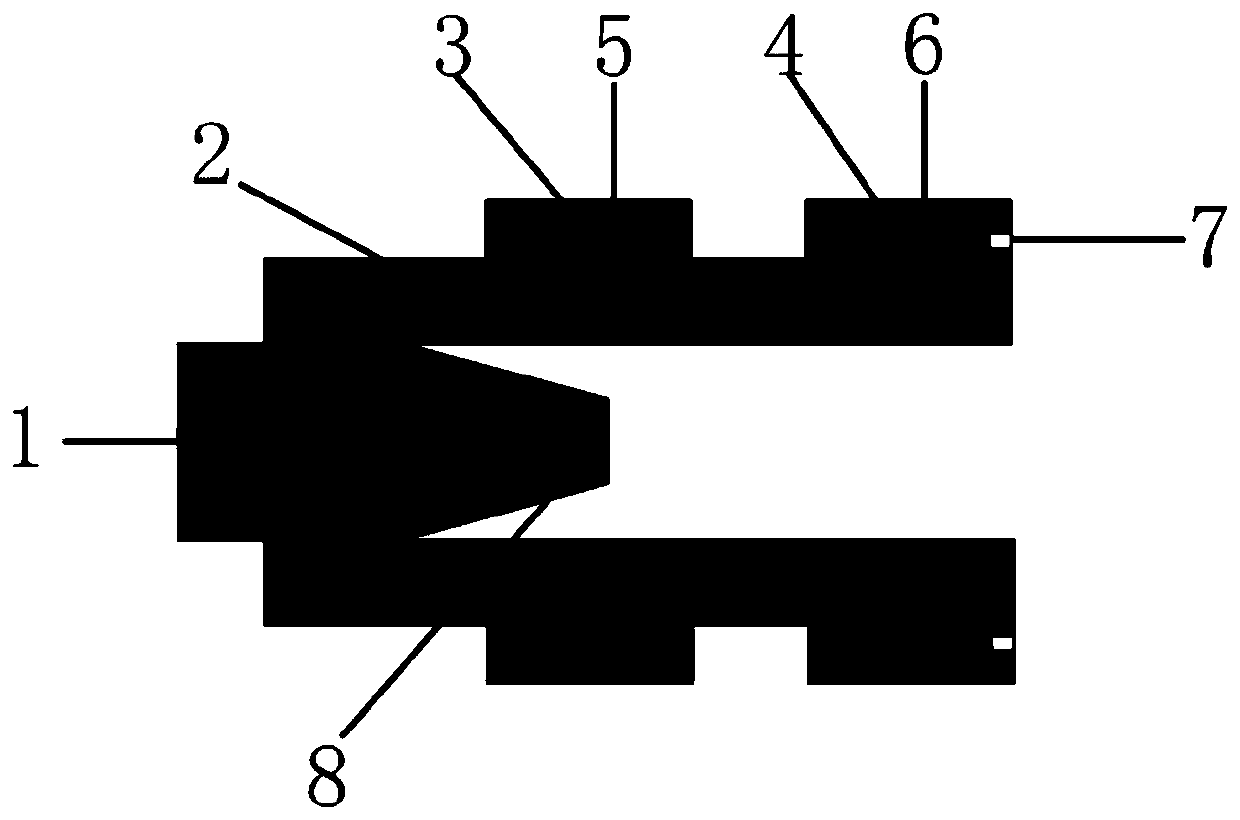

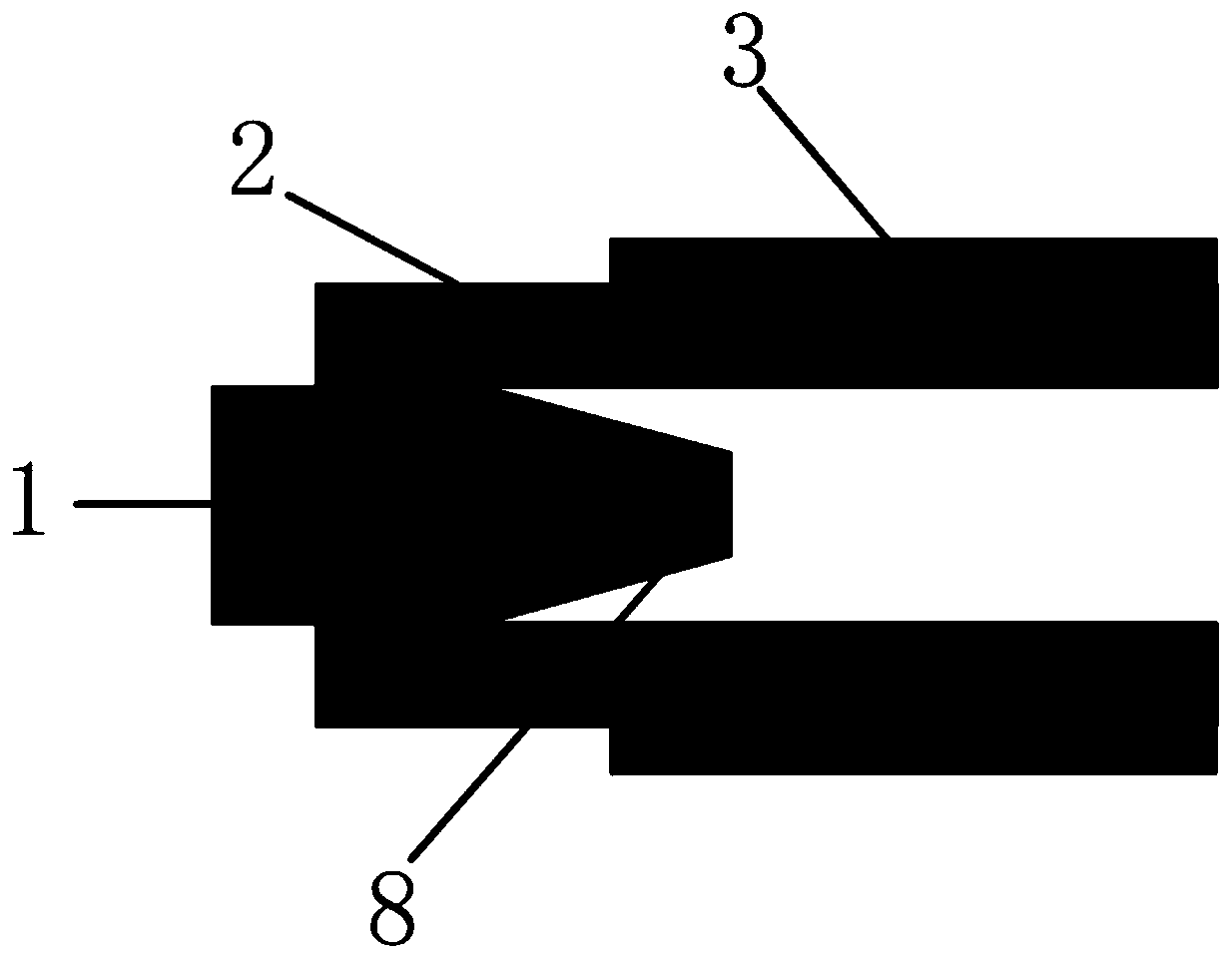

[0034] figure 1 It is a structural diagram of a pulsed vacuum arc plasma thruster with segmented microporous insulated anodes according to an embodiment of the present invention, referring to figure 1 , the pulsed vacuum arc plasma thruster includes: a cathode 1, an insulating sleeve 2, a first anode 3 and a second anode 4; the insulating sleeve is set on the outer surface of the cathode 1, and the insulating sleeve is a hollow cylindrical structure , the inside of the insulating sleeve is partially in contact with the outer surface of the cathode; the first anode 3 and the second anode 4 are spaced on the outer surface of the insulating sleeve 2, and one end with micropores of the second anode 2 is insulated from the Socket ends flush. The outer surface of the insulating sleeve 2 is in contact with the inner surfaces of the first anode 3 and the second anode 4, the first anode 3 is close to the cathode 1, the second anode 4 is far away from the cathode 1, and the outer surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com