Miniaturized cylindrical conformal microstrip array antenna

A technology of microstrip array and array antenna, which is applied in the direction of antenna, antenna array, space feed array, etc., can solve the problems of multi-order, gain reduction, and large volume, and achieve good flexibility, small antenna radiation influence, and small volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

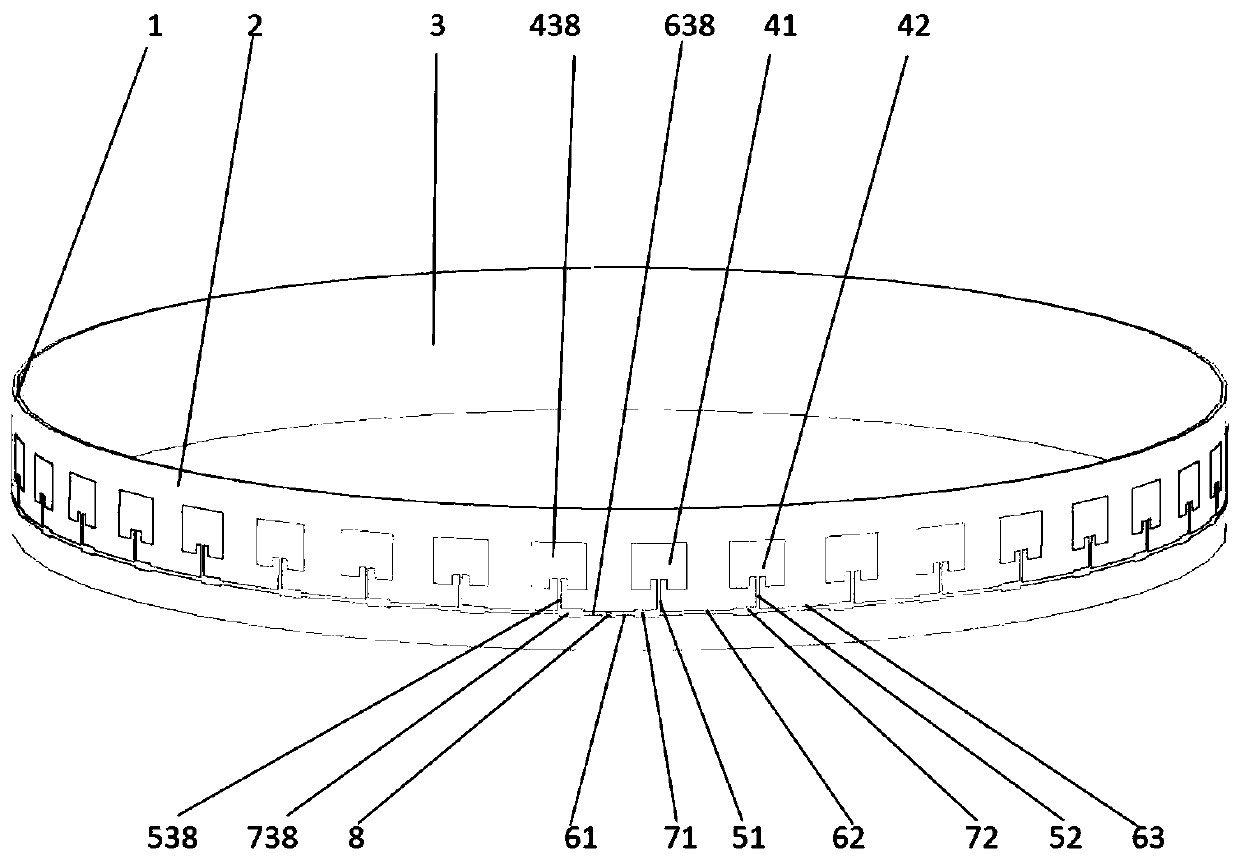

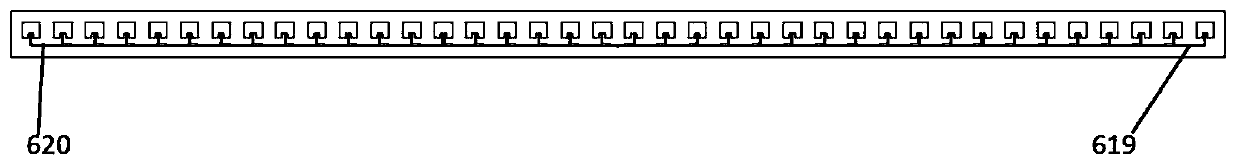

[0024] like figure 1 , 2 As shown, a miniaturized cylindrical conformal microstrip array antenna includes a metal cylindrical conformal body 1, a rectangular dielectric substrate 2 and a metal reflective grounding layer 3 fully pasted on the lower surface of the dielectric substrate 2, and the length of the dielectric substrate 2 is The direction bending conforms to the outer surface of the metal cylinder conformal body 1;

[0025] On the upper surface of the dielectric substrate 2 , an even number of metal matching units 41 , 42 , .

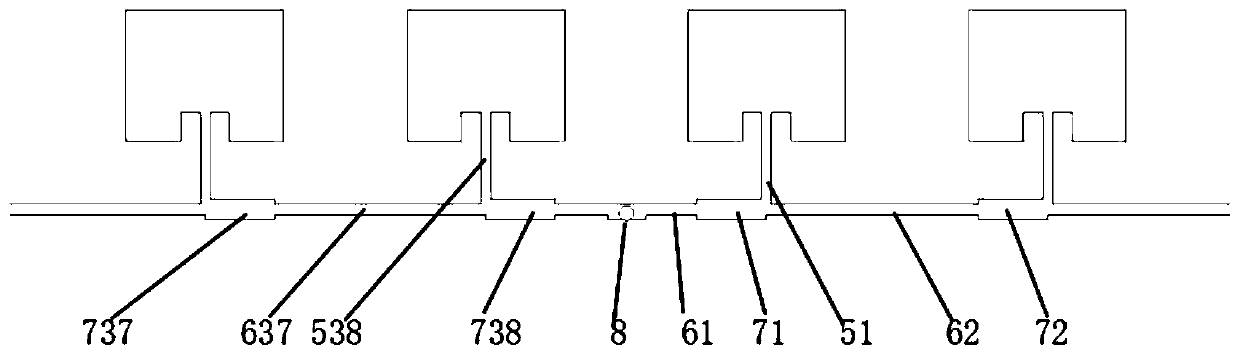

[0026] like image 3 As shown, the midpoint of the end of each metal matching unit 41 perpendicular to the axial direction of the metal cylindrical conformal body 1 is connected to one end of an axial microstrip matching line 51 parallel to the axial direction of the metal cylindrical conformal body 1, The other end of the axial microstrip matching line 51 is connected to one end of a microstrip connecting line 62 perpendicular to the axial d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com