Method for adsorbing and slowly releasing phenylethanol by Fe-based silkworm excrement biochar

A phenethyl alcohol and biochar technology, applied in separation methods, chemical instruments and methods, food science and other directions, can solve the problems of volatilization and escape of flavors and fragrances, volatilization of flavors and fragrances, and inability to release flavors and fragrances, so as to achieve repeated The effect of utilization, good adsorption capacity and slow and controlled release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

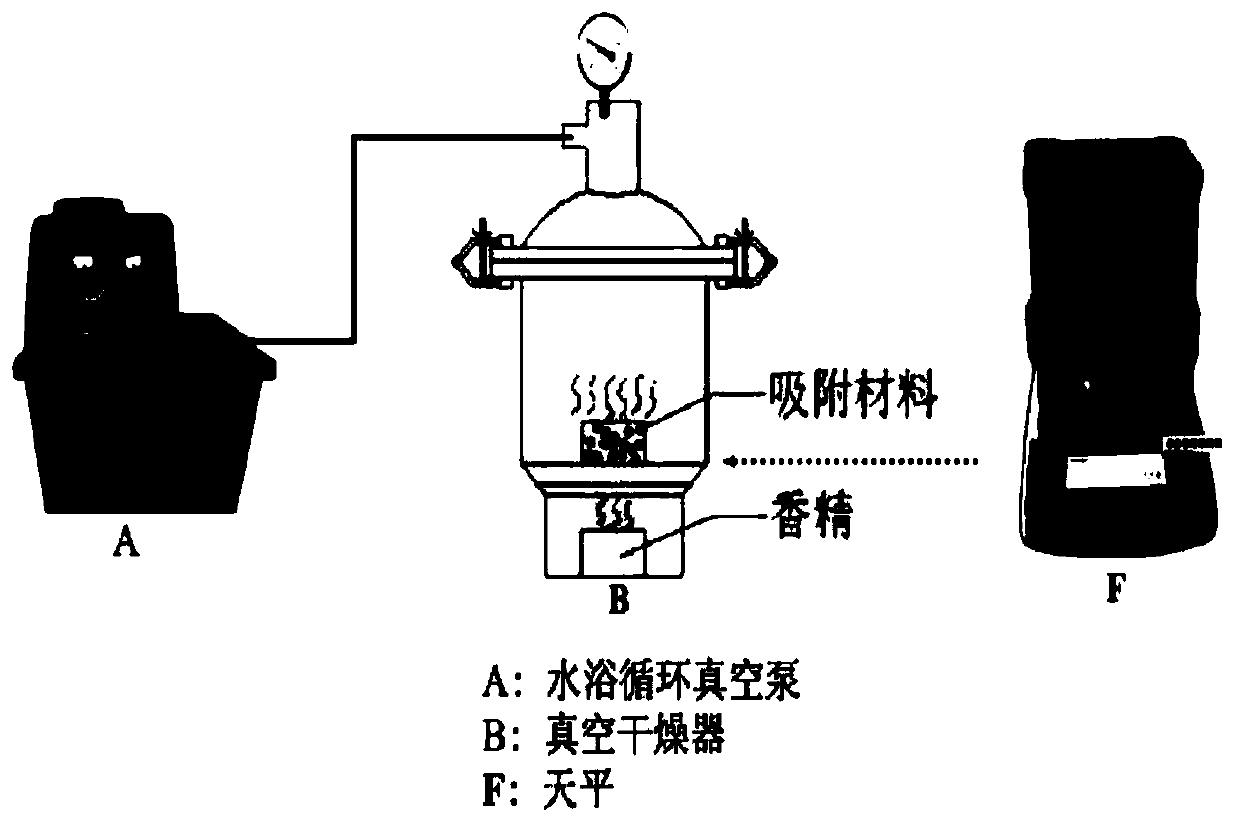

[0042] A kind of Fe-based silkworm excrement biochar adsorption slow-release method to phenylethanol, specifically comprises the following steps:

[0043](1) Adsorption: first place the open bottle of phenylethyl alcohol with a purity of 98% in the bottom of the vacuum desiccator, then put the Fe-based silkworm excrement biochar into the upper part of the vacuum desiccator, and set up the open bottle. On the mouth bottle, the weight ratio of Fe-based silkworm excrement biochar to phenylethyl alcohol is 1:30; then the vacuum dryer is pumped to a negative pressure of 0.08Mpa, and the temperature is set to 50°C to form saturated steam of phenylethyl alcohol, and then It is adsorbed into Fe-based silkworm excrement biochar, and the adsorption time is set to 3h, 6h, 9h, 12h, 15h, 24h, 36h and 48h to obtain Fe-based silkworm excrement biochar after adsorbing phenylethanol;

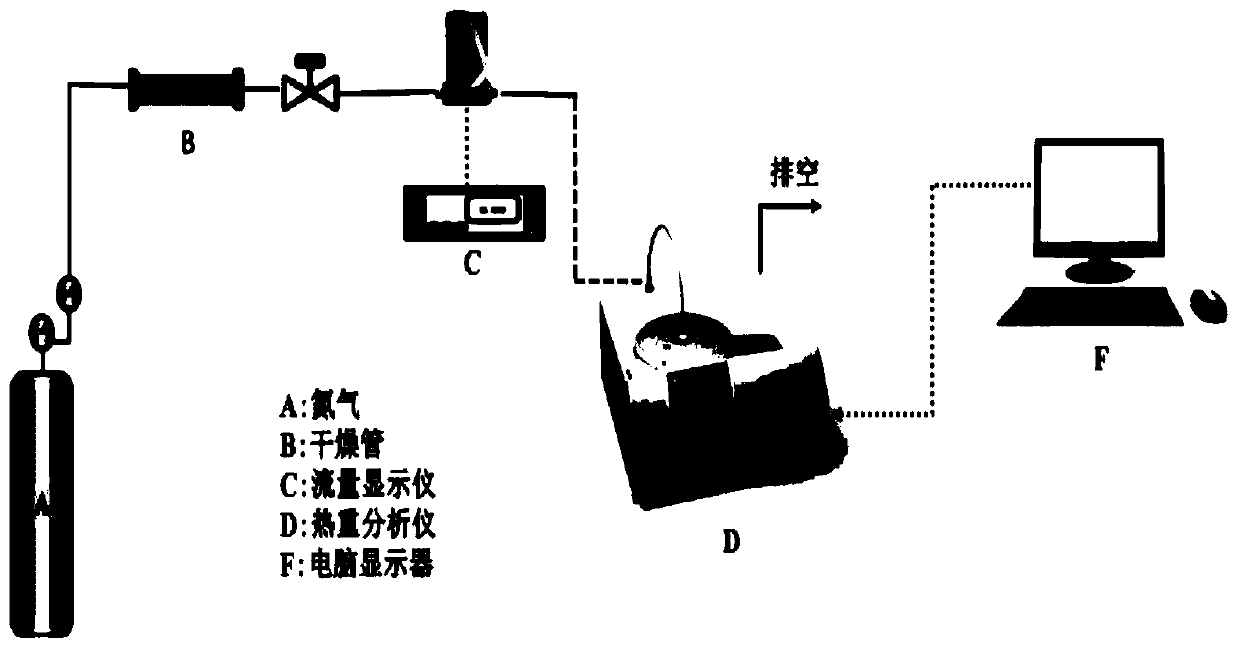

[0044] (2) Slow release: first set the temperature of the thermogravimetric analyzer to 50°C, 2 The flow rat...

Embodiment 2

[0052] A kind of Fe-based silkworm excrement biochar adsorption slow-release method to phenylethanol, specifically comprises the following steps:

[0053] (1) Adsorption: first place the open bottle of phenylethyl alcohol with a purity of 98% in the bottom of the vacuum desiccator, then put the Fe-based silkworm excrement biochar into the upper part of the vacuum desiccator, and set up the open bottle. On the mouth bottle, the weight ratio of Fe-based silkworm excrement biochar to phenylethyl alcohol is 1:30, then the vacuum dryer is pumped to a negative pressure of 0.08Mpa, and the temperature is set to 50°C to form saturated steam of phenylethyl alcohol, and then Adsorbed into Fe-based silkworm excrement biochar, set the adsorption time to 3h, 6h, 9h, 12h, 15h, 20h, and obtain Fe-based silkworm excrement biochar after adsorbing phenylethanol;

[0054] (2) Slow release: first set the temperature of the thermogravimetric analyzer to 48°C, 2 The flow rate was set to 90mL / min, ...

Embodiment 3

[0062] A kind of Fe-based silkworm excrement biochar adsorption slow-release method to phenylethanol, specifically comprises the following steps:

[0063] (1) Adsorption: first place the open bottle of phenylethyl alcohol with a purity of 98% in the bottom of the vacuum desiccator, then put the Fe-based silkworm excrement biochar into the upper part of the vacuum desiccator, and set up the open bottle. On the mouth bottle, the weight ratio of Fe-based silkworm excrement biochar to phenylethyl alcohol is 1:31, then the vacuum dryer is pumped to a negative pressure of 0.08Mpa, and the temperature is set to 48°C to form saturated steam of phenylethyl alcohol, and then Adsorbed into Fe-based silkworm excrement biochar, set the adsorption time to 3h, 6h, 9h, 12h, 15h, 20h, and obtain Fe-based silkworm excrement biochar after adsorbing phenylethanol;

[0064] (2) Slow release: first set the temperature of the thermogravimetric analyzer to 47°C, 2 The flow rate was set to 80mL / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com