Printing ink containing solid waste reduction system and method

A solid waste and ink technology, applied in the direction of solid waste removal, etc., can solve the problems of waste film slag leakage, high moisture content of film residue, high disposal costs, etc., to avoid leakage, easy operation of equipment, and reduce Effect of Disposal Charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

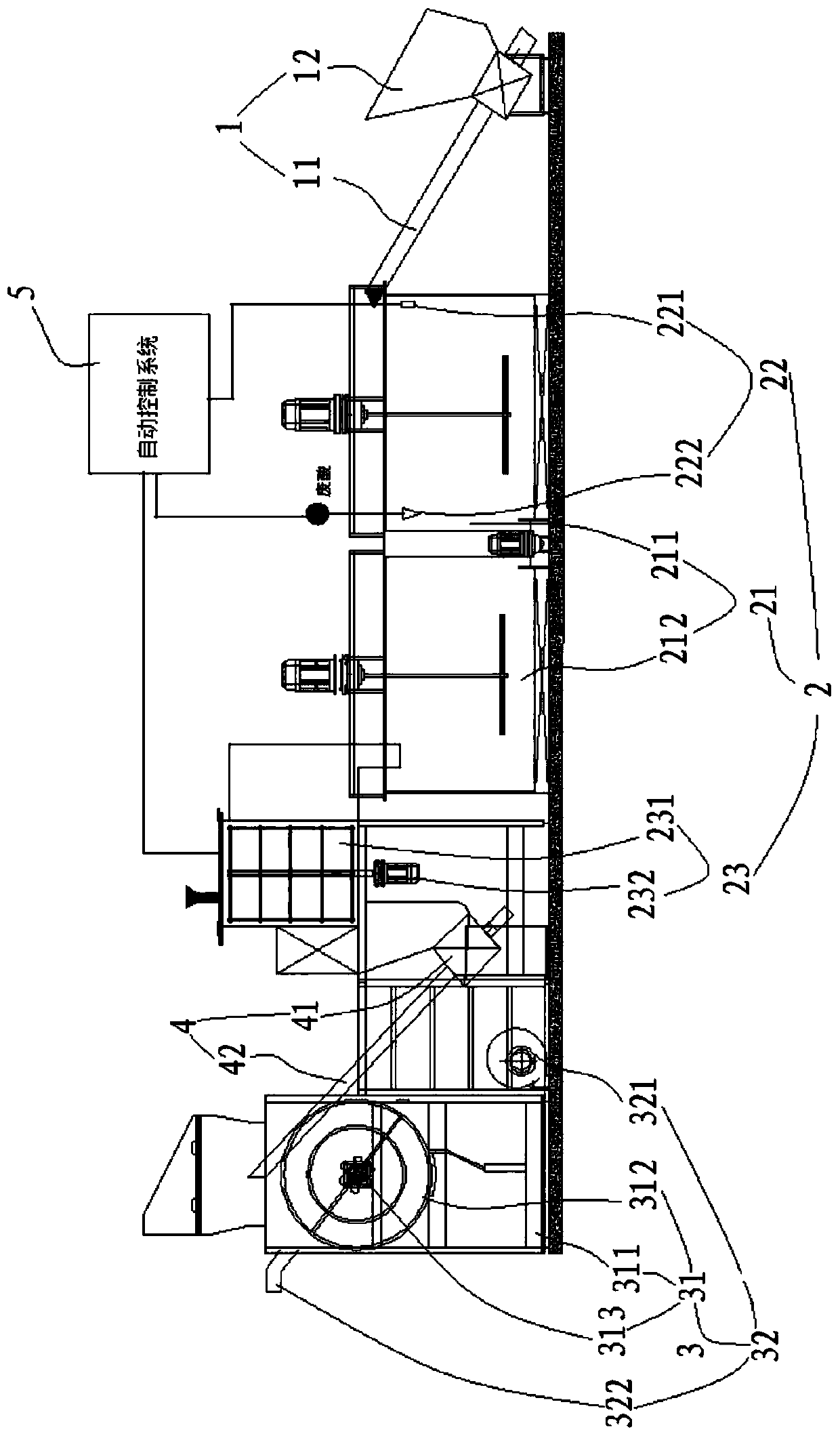

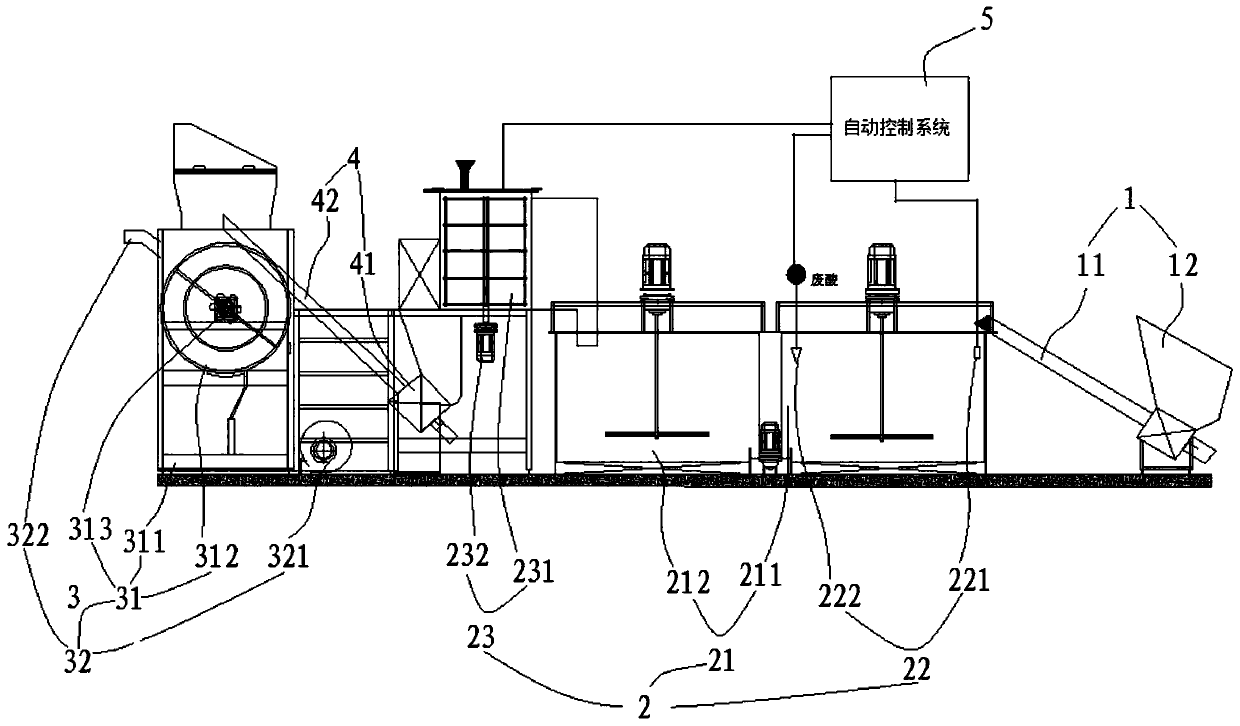

[0013] Such as figure 1 As shown, the present invention provides an ink-containing solid waste reduction system, including a feeding mechanism 1 , primary reduction equipment 2 , secondary reduction equipment 3 , transfer equipment 4 and an automatic control system 5 .

[0014] The feeding mechanism 1 is installed at the front end of the primary reduction device 2, and the rear end of the primary reduction device 2 and the front end of the secondary reduction device 3 are connected through the transfer device 4 .

[0015] The primary reduction equipment 2 includes a stirring device 21 for stirring waste materials, a pH adjusting device 22 for adding acidic materials to waste materials, and a centrifugal extrusion device 23 for centrifugally drying waste materials.

[0016] The secondary reduction equipment 3 includes a drying device 31 and a steam-water separation device 32 .

[0017] The automatic control system 5 is used to control the operation of the stirring device 21 ,...

Embodiment 2

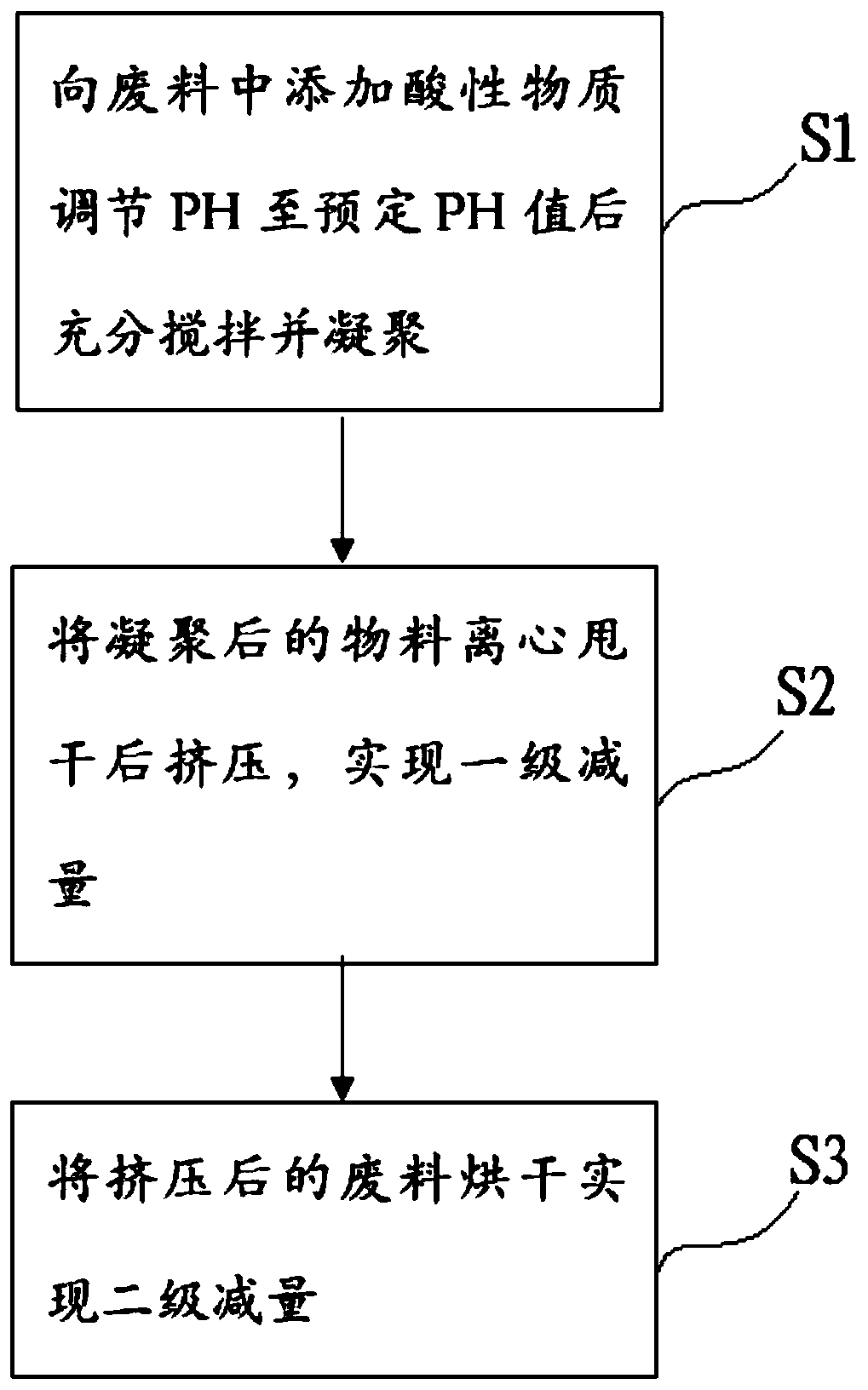

[0031] The present invention also provides a method for reducing the amount of ink-containing solid waste, comprising the following steps:

[0032] S1, add acidic substances to the waste to adjust the pH to a predetermined pH value, then fully stir and coagulate;

[0033] S2, the condensed material is centrifugally dried and then extruded to achieve a first-level reduction;

[0034] S3, drying the extruded waste to achieve secondary weight reduction.

[0035] Wherein, the predetermined pH value in step S1 is 6.5-8.5; the drying time of the waste in step S3 is 7-8 hours.

[0036] The ink-containing solid waste reduction method provided in Example 2 of the present invention utilizes the chemical properties of the wet film / dry film and the ink, and utilizes the characteristics of solidification after acidification, and achieves a reduction in solid-liquid separation after centrifugal extrusion, and then Entering the baking system for high-temperature drying to achieve secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com