System and method for online detecting service life of polishing pad

A polishing pad and life technology, which is applied in grinding/polishing equipment, parts of grinding machine tools, control of workpiece feed movement, etc., can solve the problem of inconsistent polishing pad wear, product yield and yield decline, and production efficiency. and other problems, to achieve the effect of improving the quality of flattening, making full use of it, and making small changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

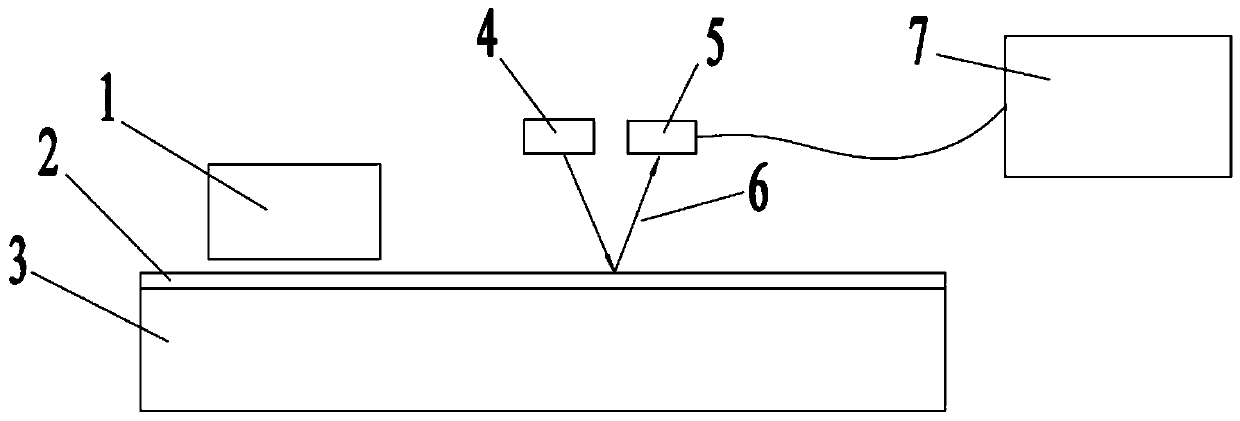

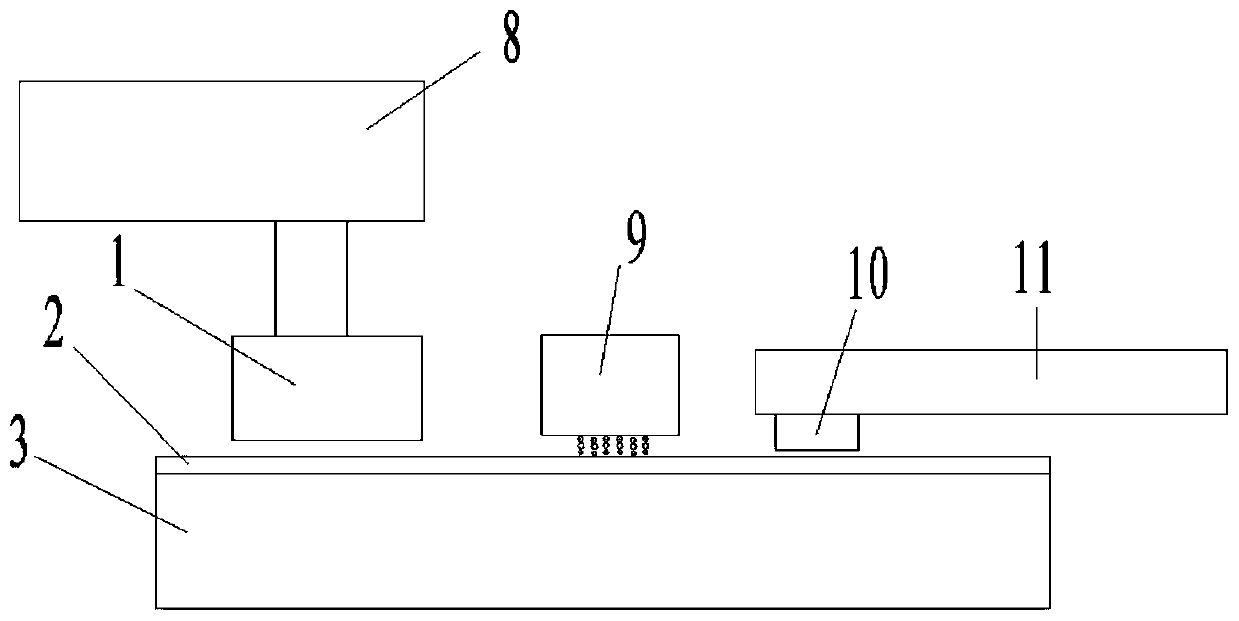

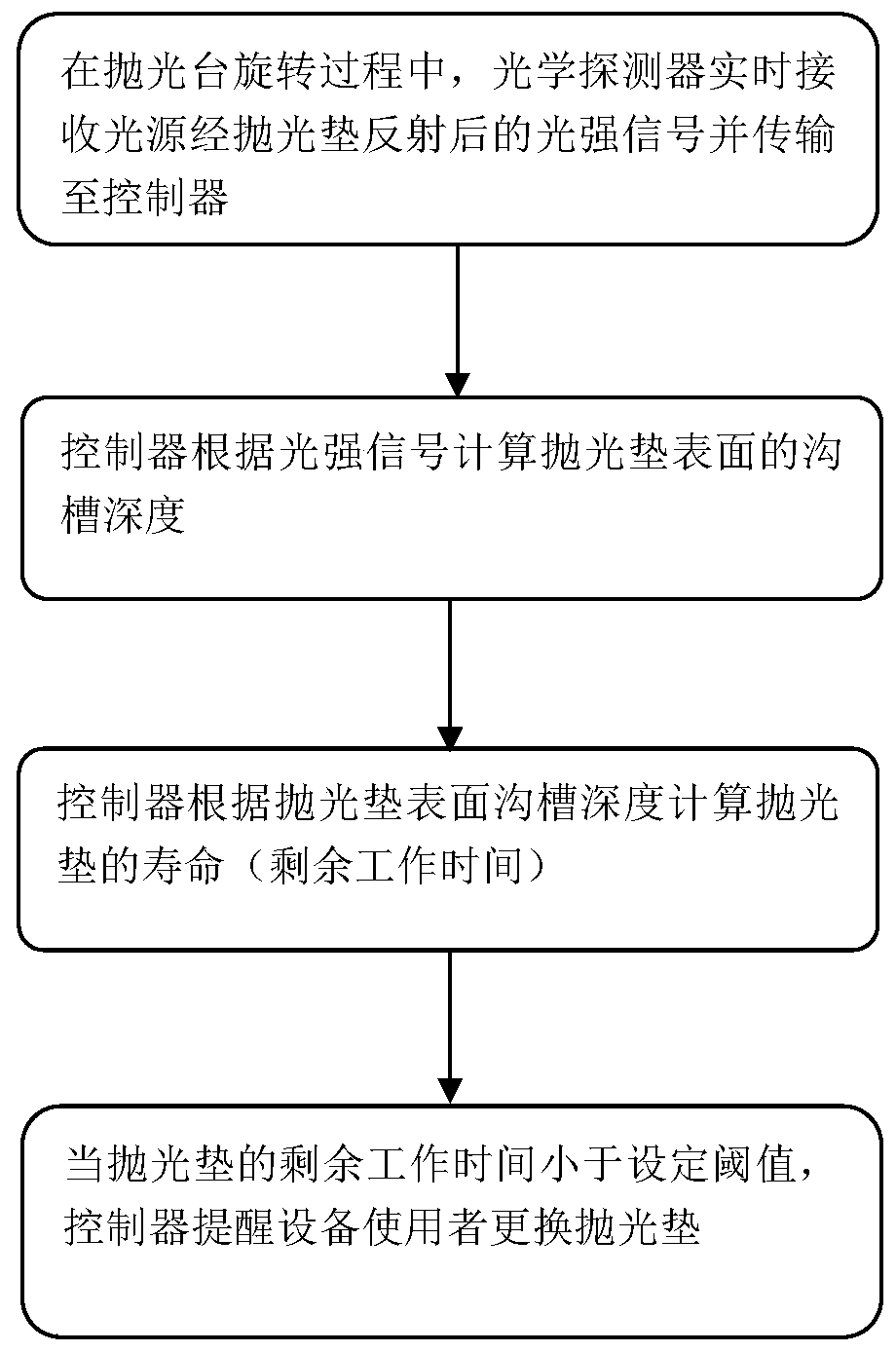

[0041] refer to figure 1 and figure 2 Shown, provide an embodiment of the online detection system of polishing pad life:

[0042] The system includes a polishing table 3 , the polishing pad 2 with grooves is pasted on the upper surface of the polishing table 3 and rotates together with the polishing table 3 . A light source 4 and an optical detector 5 are arranged above the polishing area. The light source 4 emits a light beam 6 to the surface of the polishing pad 2 and is reflected to the optical detector 5 by the surface of the polishing pad 2 .

[0043] The light source 4 and the optical detector 5 may be an integrated photoelectric sensor; or, the light source 4 and the optical detector 5 may be independent components.

[0044] A polishing head 1 carrying a wafer is arranged above the polishing table 3 , and the light source 4 and the optical detector 5 can be installed on a polishing arm 8 that fixes the polishing head 1 .

[0045] A nozzle for supplying polishing liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com