Bamboo tube cutting equipment for bamboo product machining

A technology for cutting equipment and bamboo products, which is applied in the direction of manufacturing tools, mechanical equipment, wood processing appliances, etc. It can solve the problems of inconsistent length of bamboo tubes and uneven incisions of bamboo tubes, so as to avoid random rolling, convenient operation, and smooth incisions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

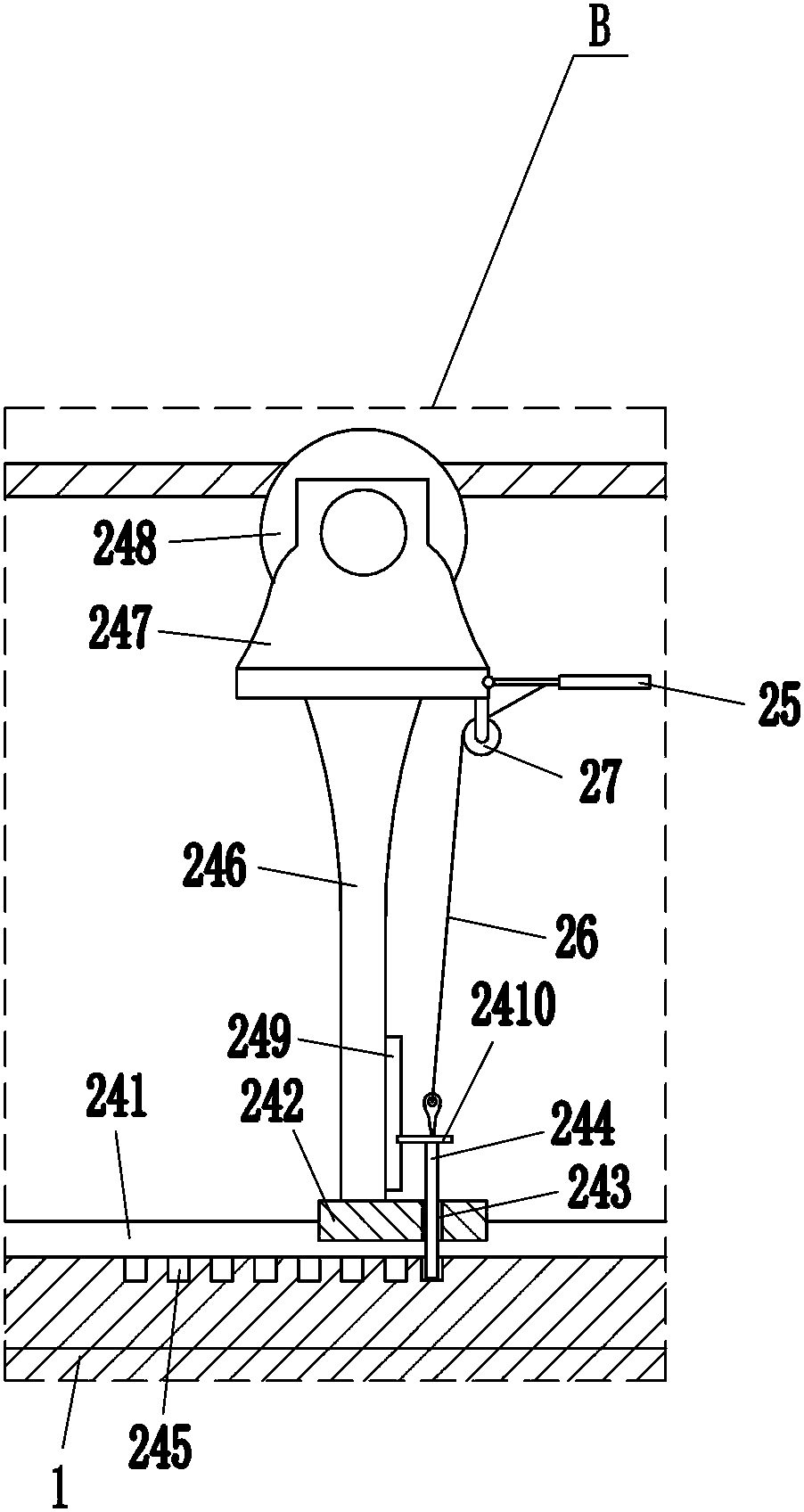

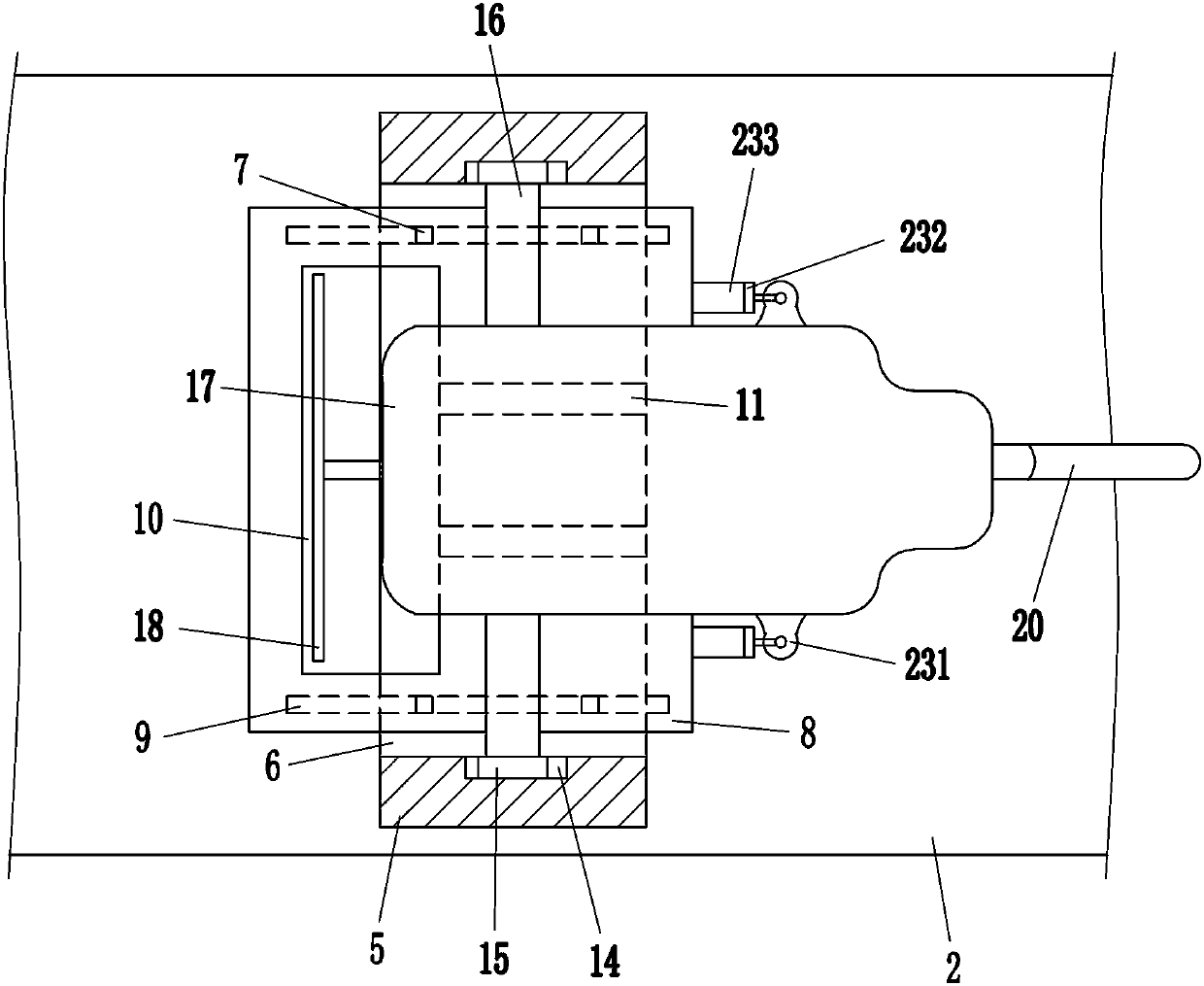

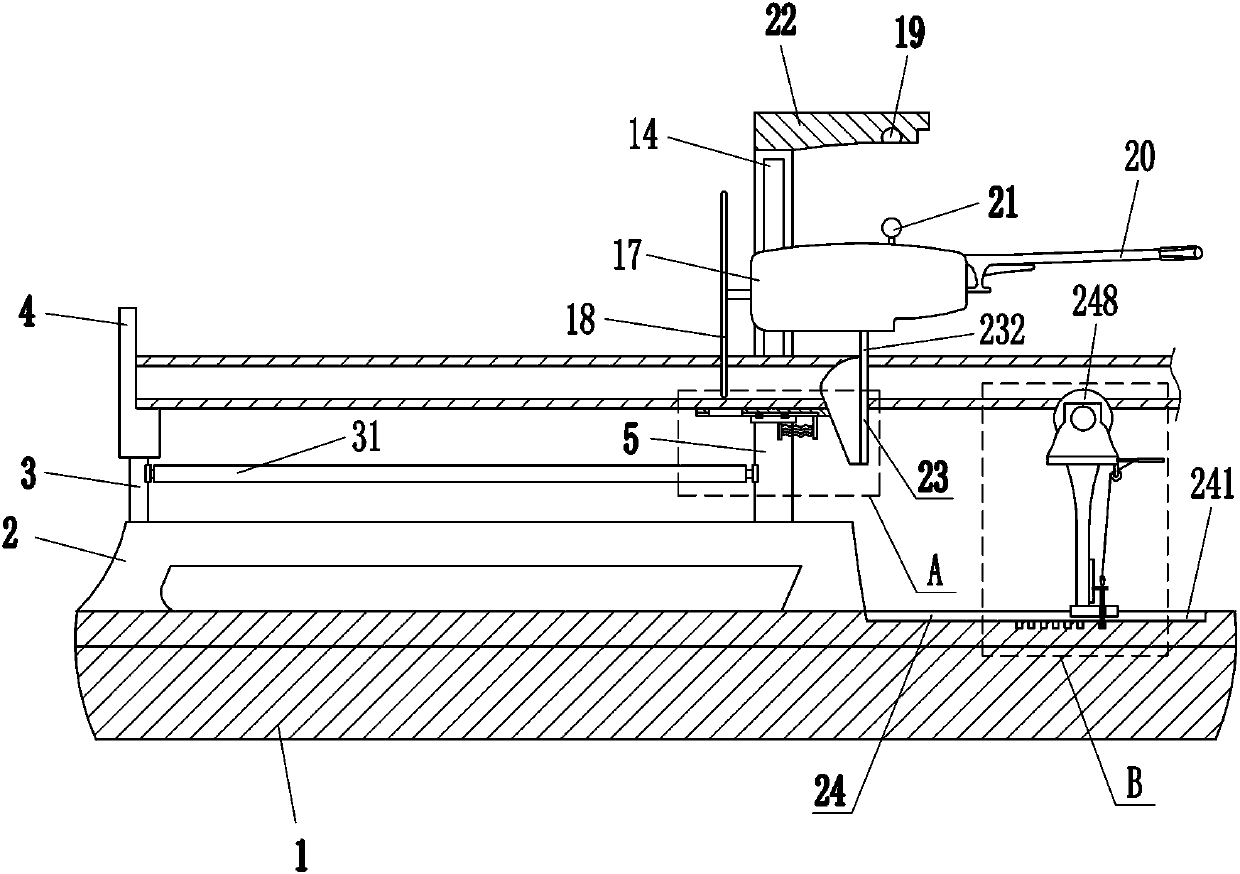

[0018] A kind of bamboo tube cutting equipment for bamboo products processing, such as Figure 1-3 As shown, it includes a base 1, a mounting frame 2, a support plate 3, a support plate 4, a vertical plate 5, a horizontal plate 6, a slider 7, a moving plate 8, an arc block 11, a connecting block 12, a spring 13, and a guide block 15. Connecting plate 16, motor 17, cutter 18, handle 20, block 21, connecting plate 22 and extruding mechanism 23, the left side of the top of the base 1 is bolted with a supporting mounting frame 2, and the base 1 is connected by bolts The way to connect with the installation frame 2, the left side of the top of the installation frame 2 is fixedly connected with the support plate 3, the top of the support plate 3 is connected with the support plate 4, and there are two supporting vertical plates 5, which are respectively arranged on the right side of the top of the installation frame 2 The vertical plates 5 are connected to the installation frame 2 b...

Embodiment 2

[0020] A kind of bamboo tube cutting equipment for bamboo products processing, such as Figure 1-3 As shown, it includes a base 1, a mounting frame 2, a support plate 3, a support plate 4, a vertical plate 5, a horizontal plate 6, a slider 7, a moving plate 8, an arc block 11, a connecting block 12, a spring 13, and a guide block 15. Connecting plate 16, motor 17, cutter 18, handle 20, block 21, connecting plate 22 and extruding mechanism 23, the top left side of base 1 is bolted with mounting frame 2 which plays a supporting role, and the top left side of mounting frame 2 is The side is fixedly connected with a support plate 3, and the top of the support plate 3 is connected with a support plate 4. There are two supporting vertical plates 5, which are respectively arranged on the front and rear sides on the right side of the top of the mounting frame 2. The lower part between the two vertical plates 5 A horizontal plate 6 is fixedly connected, and the front side of the top of...

Embodiment 3

[0023] A kind of bamboo tube cutting equipment for bamboo products processing, such as Figure 1-4As shown, it includes a base 1, a mounting frame 2, a support plate 3, a support plate 4, a vertical plate 5, a horizontal plate 6, a slider 7, a moving plate 8, an arc block 11, a connecting block 12, a spring 13, and a guide block 15. Connecting plate 16, motor 17, cutter 18, handle 20, block 21, connecting plate 22 and extruding mechanism 23, the top left side of base 1 is bolted with mounting frame 2 which plays a supporting role, and the top left side of mounting frame 2 is The side is fixedly connected with a support plate 3, and the top of the support plate 3 is connected with a support plate 4. There are two supporting vertical plates 5, which are respectively arranged on the front and rear sides on the right side of the top of the mounting frame 2. The lower part between the two vertical plates 5 A horizontal plate 6 is fixedly connected, and the front side of the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com