Polycarbonate as well as preparation method and application thereof

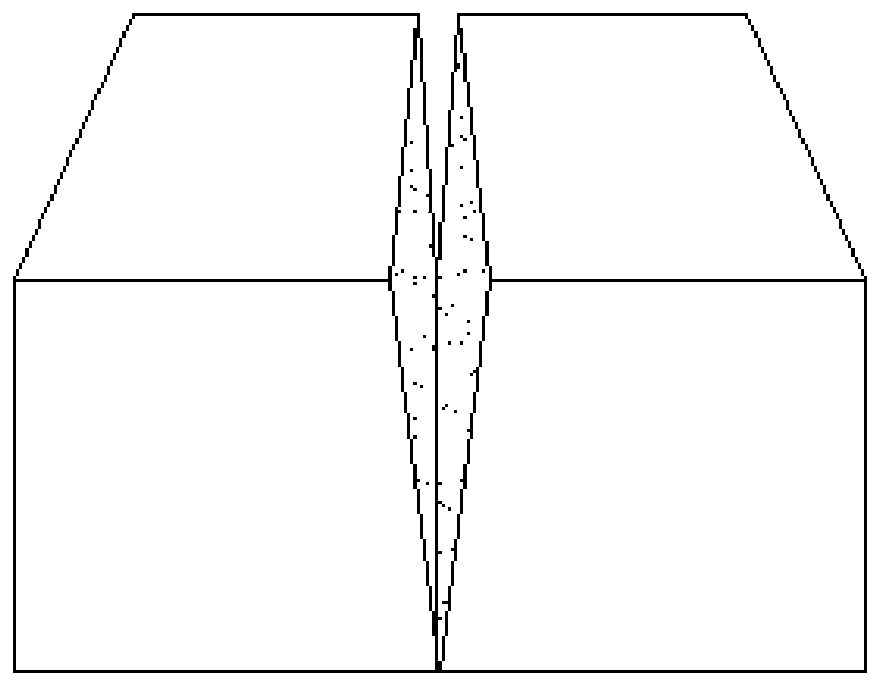

A technology of polycarbonate and polycarbonate diol, which is applied in the field of self-healing materials, can solve the problems of poor stability of microcapsules, poor performance of hydrogen-bonded polymer materials, and low energy of ordinary hydrogen-bonded bonds, and achieve good durability Heat resistance, good internal components, and the effect of protecting internal components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The present embodiment provides a kind of polycarbonate, and its chemical structural formula is as follows:

[0034]

[0035] Wherein the preparation raw material that polycarbonate adopts comprises ureido pyrimidone type diisocyanate and the 3rd compound; Wherein the 3rd compound comprises polycarbonate diol, polyethylene glycol, ethylene glycol and polyester diol One of.

[0036] Wherein the chemical structural formula of ureido pyrimidone type diisocyanate is as follows: Described polycarbonate diol chemical structural formula is as follows:

[0037] Wherein the ratio of the ureidopyrimidinone diisocyanate to the third compound is 20-45:34-89.

[0038] The raw materials used for the preparation of the ureido pyrimidinone type diisocyanate include a first compound and a second compound; wherein the first compound includes one of pyrimidinone compounds and cytosine with an amine group; wherein the first compound The chemical structures of the two compounds inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com