Functionalized oriented fibers for tissue-engineered vascular scaffold construction and preparation method thereof

A functionalization and orientation technology, applied in fiber treatment, fiber type, pharmaceutical formulation, etc., can solve the problems of lack of activity of polyamino functional groups and complicated preparation process, and achieve the effect of enhancing application efficacy, simple process, and enhancing coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] At room temperature, dissolve 0.57 g of PLCL (the copolymerization ratio of lactic acid and caprolactone is 50:50, and the viscosity is 2.9 dl / g) in 6 mL of hexafluoroisopropanol, and stir for 12 hours to obtain a mass fraction of 10% Spinning solution: Electrospinning is carried out at room temperature and humidity of 40-60%, the applied voltage is 5kV, the receiving distance is 20cm, the drum receiving speed is 1000rpm, and the injection rate is 0.5mL / h.

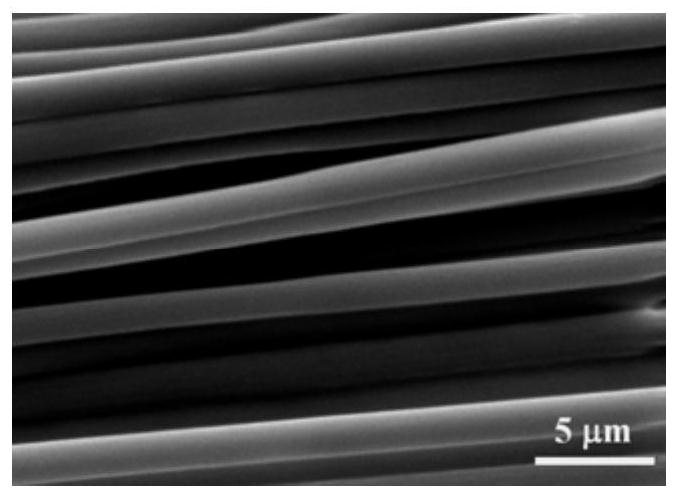

[0040] The scanning electron micrographs of the prepared pure PLCL oriented fibers, such as figure 1 As shown, it shows that it has a highly oriented structure, and the fiber diameter is 1.67±0.17 μm.

[0041] Cell adhesion after 3 hours of planting ECs on the scaffold, such as Figure 7As shown, the expression of the cell function protein VE-Cadherin after the scaffold was planted with ECs for 3 days, as shown in Figure 10 As shown, although PLCL-oriented fibers can maintain the functional expression of ECs, th...

Embodiment 2

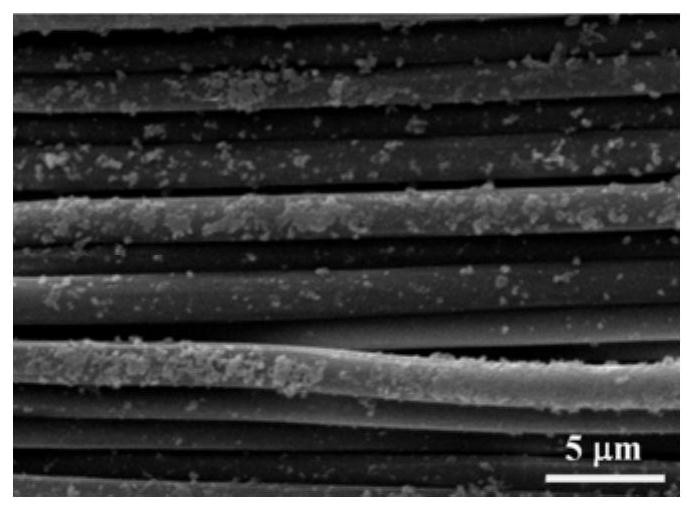

[0044] At room temperature, dissolve 0.57 g of PLCL (the copolymerization ratio of lactic acid and caprolactone is 50:50, and the viscosity is 2.9 dl / g) in 6 mL of hexafluoroisopropanol, and stir for 12 hours to obtain a mass fraction of 10% Spinning solution: Electrospinning is carried out at room temperature and humidity of 40-60%, the applied voltage is 5kV, the receiving distance is 20cm, the drum receiving speed is 1000rpm, and the injection rate is 0.5mL / h. Dissolve 20 mg of DA and 2 mg of Lys in 10 mL of Tris buffer solution with a concentration of 10 mM and a pH of 8.5, stir and dissolve to prepare a DA / Lys solution. A 1 cm×1 cm oriented fiber-based scaffold was immersed in the DA / Lys solution, and vibrated at room temperature for 24 h at a vibration rate of 100 times / min to obtain PDA / Lys modified oriented fibers. SEM images of oriented fibers modified by PDA / Lys, such as image 3 As shown, the granular aggregates on the fiber surface began to increase, and the furth...

Embodiment 3

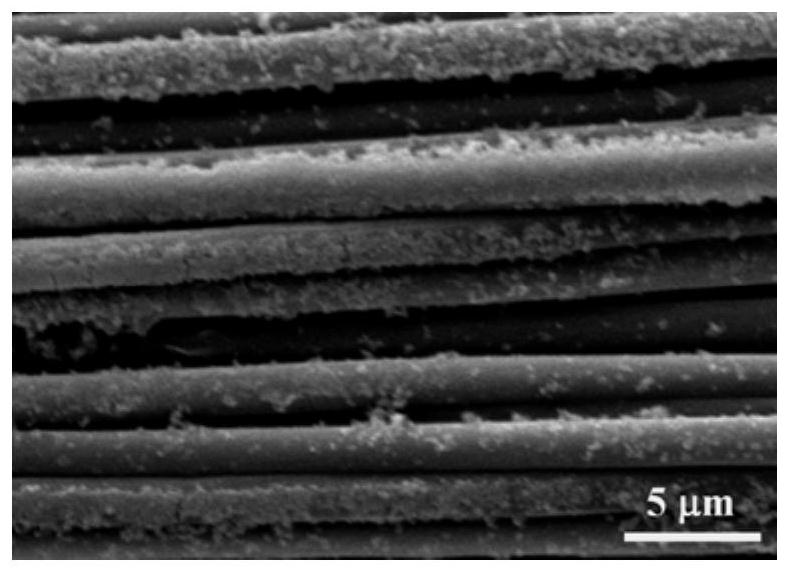

[0046] At room temperature, dissolve 0.57 g of PLCL (the copolymerization ratio of lactic acid and caprolactone is 50:50, and the viscosity is 2.9 dl / g) in 6 mL of hexafluoroisopropanol, and stir for 12 hours to obtain a mass fraction of 10% Spinning solution: Electrospinning is carried out at room temperature and humidity of 40-60%, the applied voltage is 5kV, the receiving distance is 20cm, the drum receiving speed is 1000rpm, and the injection rate is 0.5mL / h. Dissolve 20 mg of DA and 10 mg of Lys in 10 mL of Tris buffer solution with a concentration of 10 mM and a pH of 8.5, stir and dissolve to prepare a DA / Lys solution. A 1 cm×1 cm oriented fiber-based scaffold was immersed in the DA / Lys solution, and vibrated at room temperature for 24 h at a vibration rate of 100 times / min to obtain PDA / Lys modified oriented fibers. SEM images of oriented fibers modified by PDA / Lys, such as Figure 4 As shown, it shows that the granular aggregates on the fiber surface begin to decreas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com