Method and system for controlling engine fueling

An engine and fuel technology, applied in engine control, engine components, machines/engines, etc., can solve problems such as AFR fluctuation, vapor escape, vapor pressure accumulation limit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

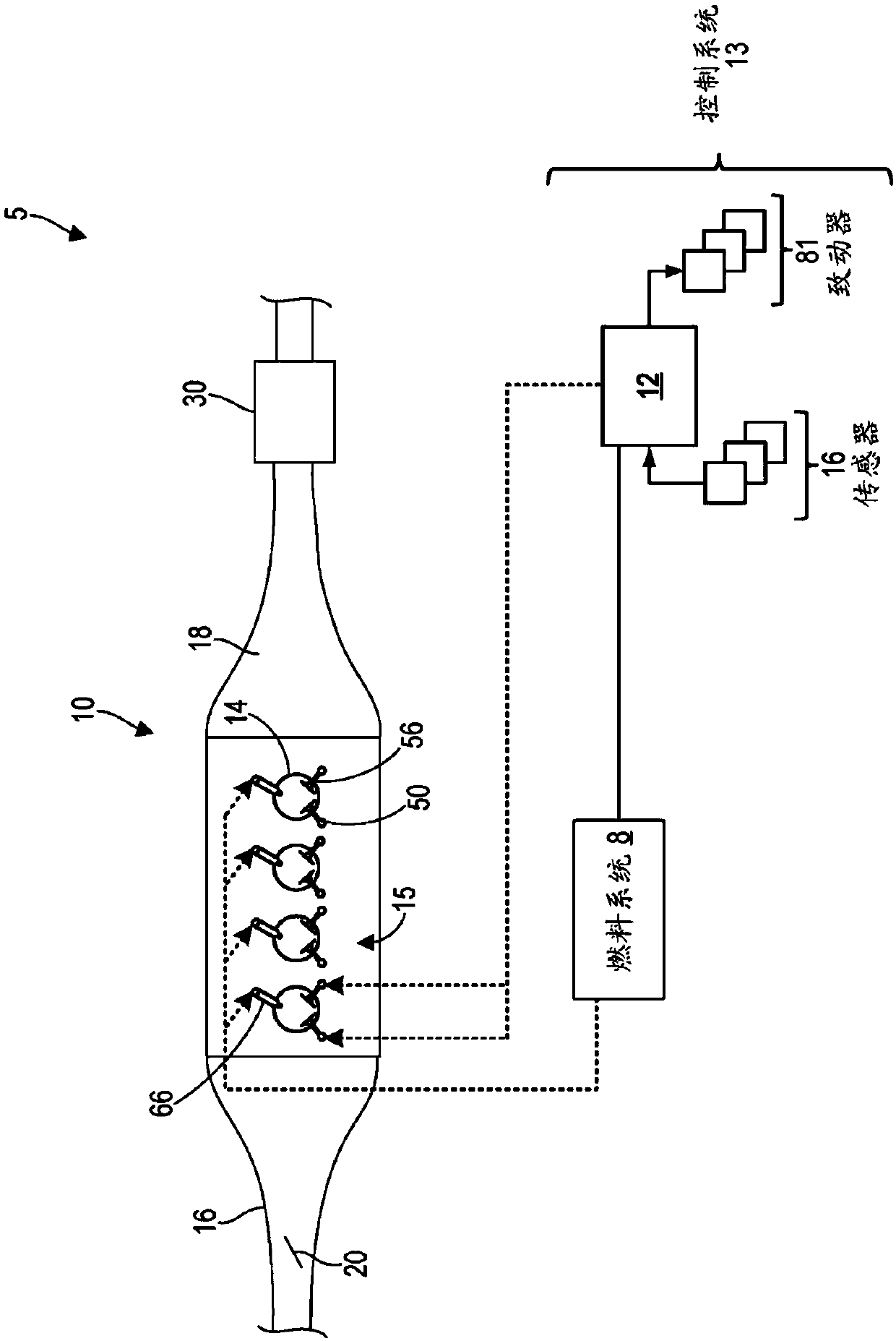

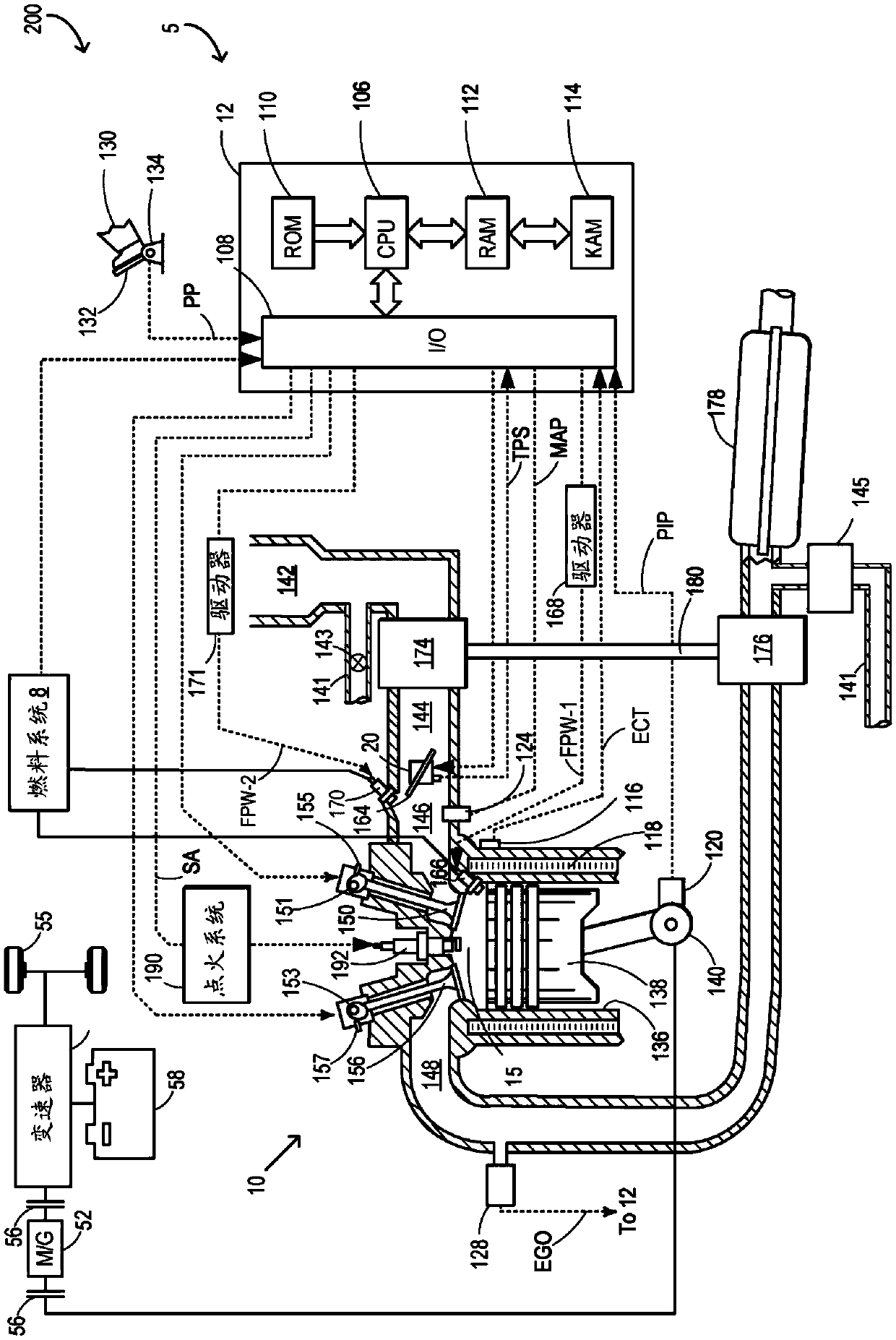

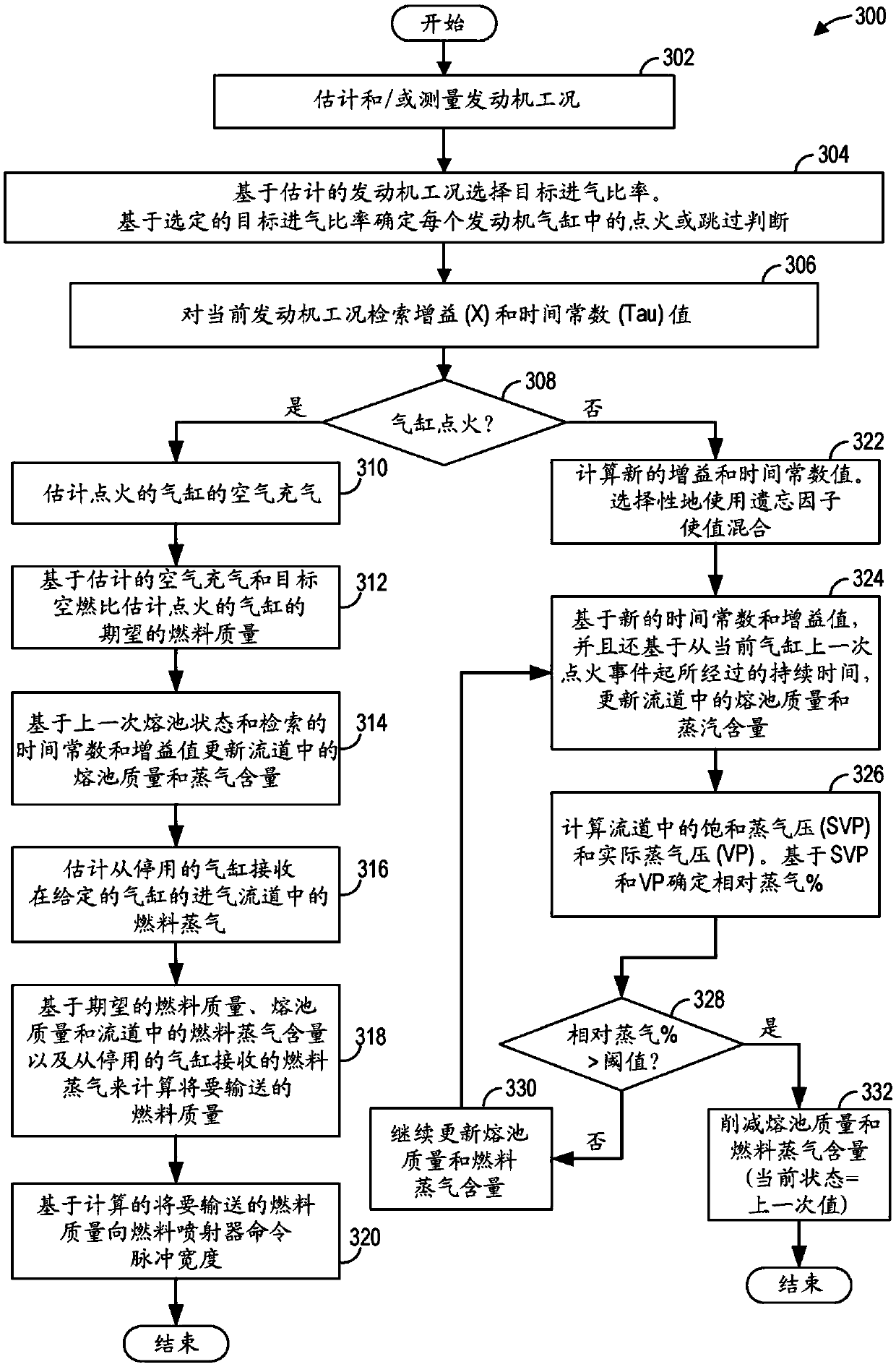

[0017] Provided for use in an engine configured for selective cylinder deactivation in operation such as figure 1 and figure 2 A method and system for adjusting the amount of fuel delivered to cylinders of an engine. The engine controller can execute control programs such as image 3 An exemplary routine to update the fuel pool dynamics for each cylinder based on the cylinder's intake state and based on the given cylinder's firing history. The controller can select gains and time constants to apply to the X-Tau model for transient fuel compensation, such as according to Figure 4 and Figure 5 to compensate for the different fuel pool dynamics of fired versus skipped cylinders. Once the fuel vapor content of the cylinder reaches the saturated vapor pressure limit, the controller can also cut the fuel pool mass, such as Figure 6 shown. exist Figure 7 Exemplary fuel supply adjustments are shown in the prophetic example of , which account for changing fuel pool dynamics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com