High-frequency pit-type pipe

A technology of pitting and high frequency, applied in the field of high-frequency pitting tube, can solve the problem of low heat dissipation efficiency, and achieve the effect of high heat dissipation efficiency, increased contact area, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

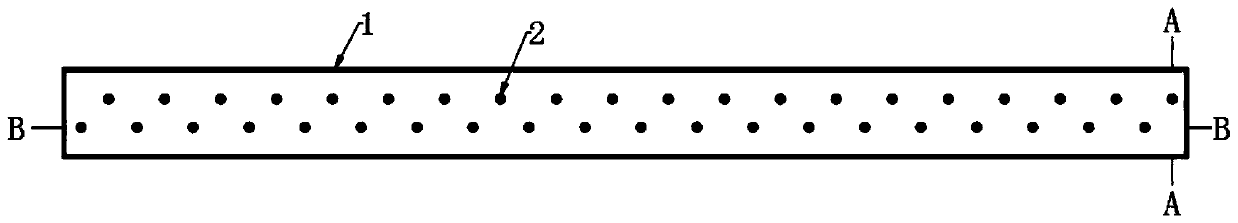

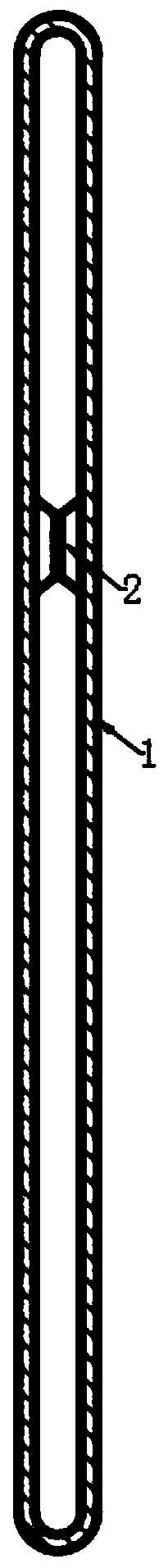

[0022] as attached figure 1 to attach Figure 5 Shown:

[0023] The invention provides a high-frequency pitted tube, which includes a heat dissipation pitted tube 1 and a groove point 2; There is a gap of 5 mm between the opposite groove points 2 .

[0024] Wherein, the pitted heat dissipation tube 1 has a flat mouth structure.

[0025] Wherein, the groove points 2 on both sides of the heat dissipation pitted pipe 1 are symmetrical structures, which facilitates the welding of the symmetrical groove points 2 on both sides when the inner side of the heat dissipation pitted pipe is brazed in a brazing furnace, thereby improving the heat dissipation pitting. The strength of the tube 1 can also increase the contact area in the radiator cavity.

[0026] Wherein, when the heat dissipation pitted pipe 1 is brazed in a brazing furnace, the inner groove point 2 is welded, which improves the strength of the heat dissipation pitted pipe 1, and at the same time increases the contact ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com