Closed-circuit sampler special for aviation oil quality detection

A technology of sampler and aviation oil, which is applied in the field of aviation oil testing, can solve the problems of delayed maintenance, high maintenance cost, and inflow of chemical water measuring devices, so as to avoid aviation oil pollution, reduce the circulation area, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

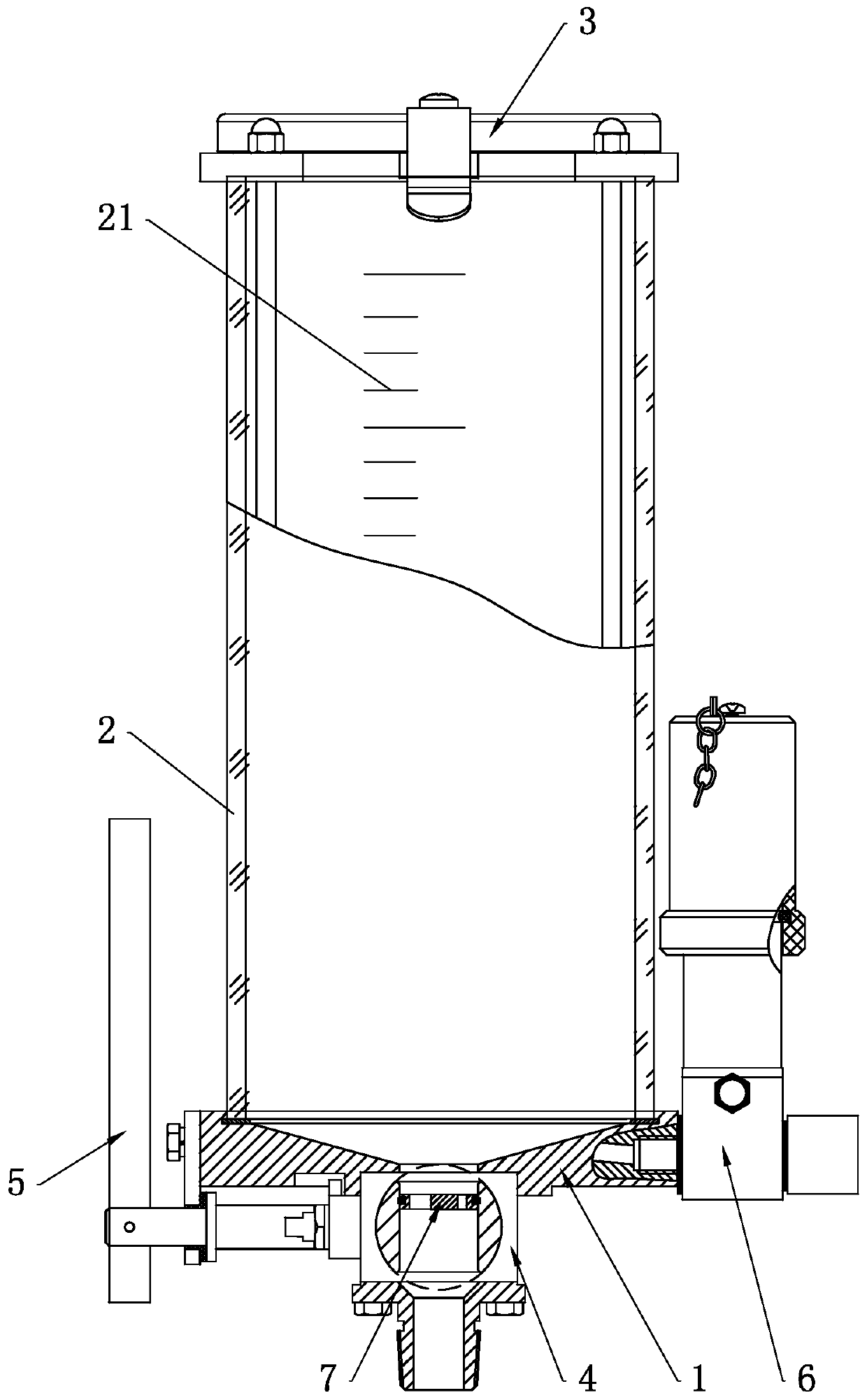

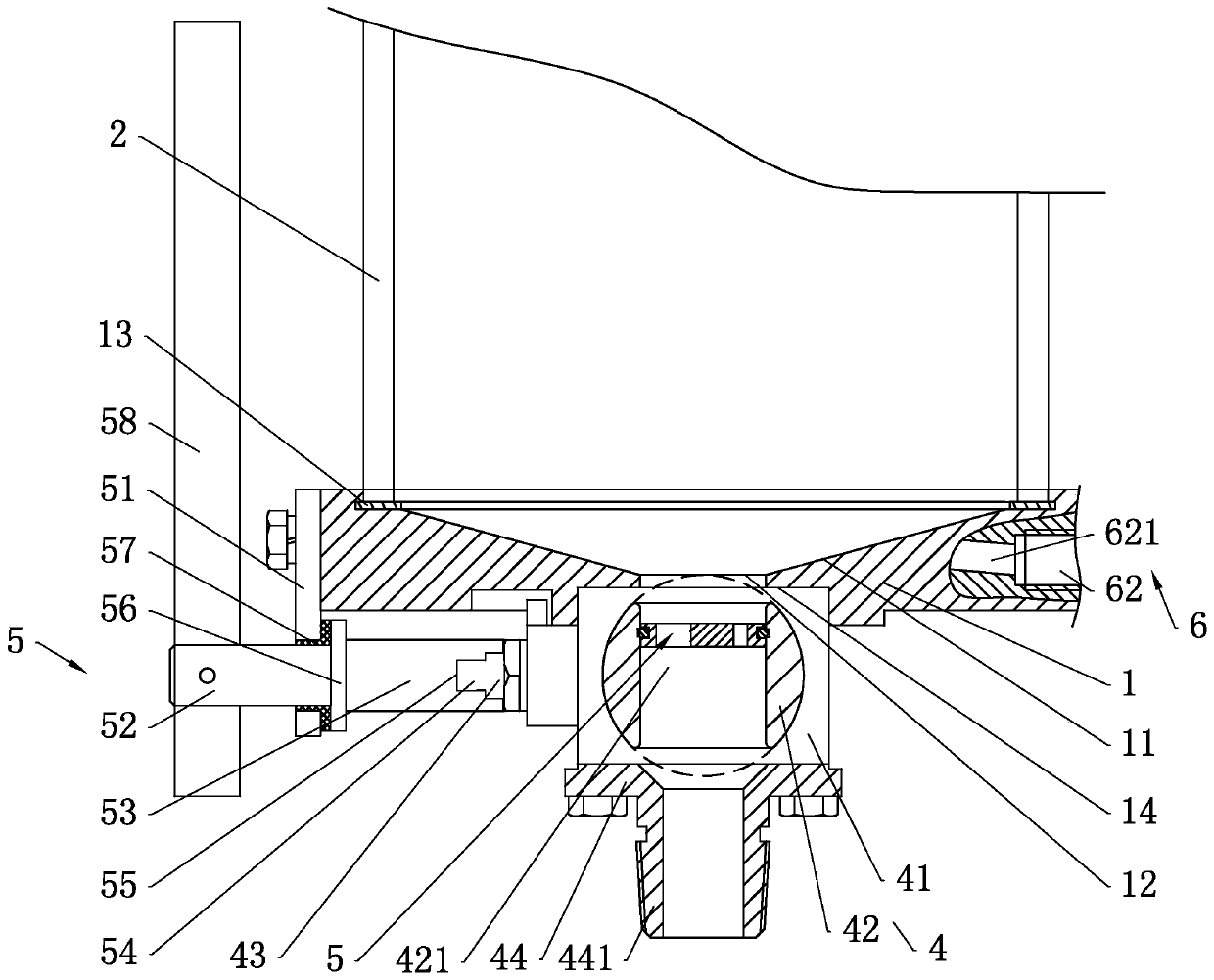

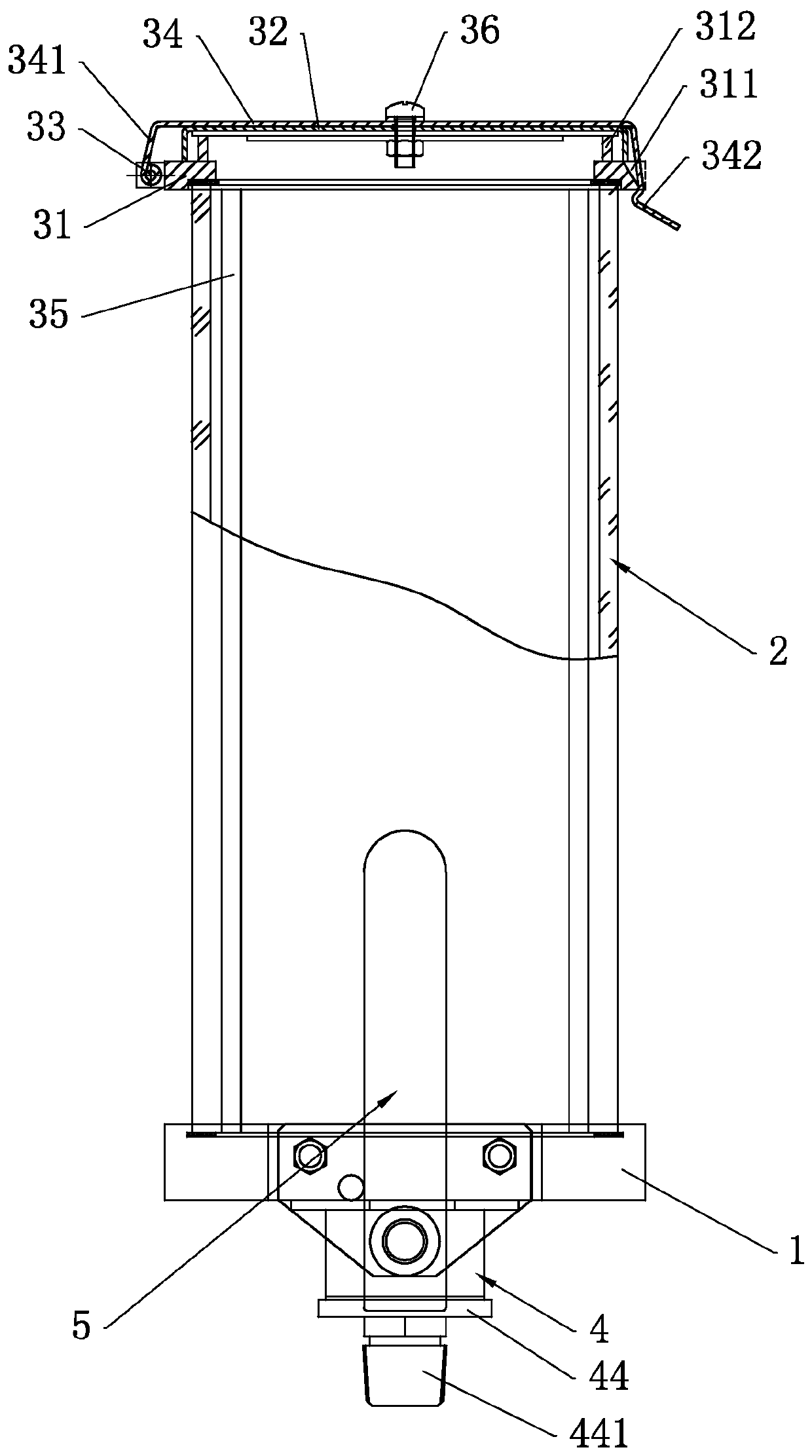

[0040] refer to figure 1 , is a closed-circuit sampler specially used for aviation fuel quality testing disclosed by the present invention, mainly including a base 1 , a glass cylinder 2 , a cover assembly 3 , a ball valve body 4 , a handle assembly 5 , and a liquid sampling assembly 6 .

[0041] refer to figure 1 with figure 2 , wherein the base 1 is arranged at the bottom for carrying the glass cylinder 2, the cover assembly 3 is arranged on the upper part of the glass cylinder 2 relative to the base to open or close the glass cylinder 2, the glass cylinder 2 is cylindrical, There are openings at both ends, and the lower part of the glass cylinder 2 is in sealing connection with the base 1 and the upper part with the cover assembly 3 .

[0042] Preferably, a scale 21 is provided on the cylinder wall of the glass cylinder 2, and the scale 21 can be provided by spraying, offset printing and the like.

[0043] Specifically, the base 1 is disc-shaped, and its upper surface i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com