Method for Improving the Coercive Force of Sintered NdFeB Magnets

A neodymium-iron-boron and coercive force technology is applied in the field of improving the coercive force of sintered neodymium-iron-boron magnets, which can solve the problems of low coercivity and large grain size of the sintered neodymium-iron-boron magnets, and improve the coercivity of the magnets. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

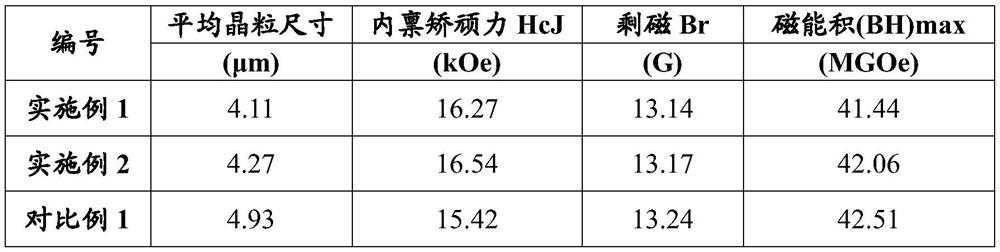

Embodiment 1

[0037] Prepare the mixture according to the following formula:

[0038] Pr-Nd alloy: 32wt%; Fe: 66.4wt%; Al: 0.5wt%; Cu: 0.1wt%; B: 1.0wt%.

[0039] Put the prepared mixture into a vacuum quick-setting casting furnace, vacuumize to 1Pa, fill it with argon protection for heating and melting, and then pour the melted liquid on the rotating cooling copper roller to obtain a thickness of about 0.3mm NdFeB alloy cast sheet.

[0040] Hydrogen crushing of NdFeB alloy castings to obtain NdFeB coarse powder, mix NdFeB coarse powder with antioxidant and lubricant for 1 hour, and then obtain NdFeB fine powder with an average particle size D50 of 3.04 μm by jet mill . Mix tungsten powder with a volume ratio of 0.5:100 (average particle diameter D50 is 500nm) and NdFeB fine powder for 1.5h to obtain mixed powder. In a 2T magnetic field, the mixed powder is subjected to orientation molding and isostatic pressing to obtain a compact; the compact is vacuum sintered at 1050°C for 2h, and th...

Embodiment 2

[0042] Prepare the mixture according to the following formula:

[0043] Pr-Nd alloy: 32wt%; Fe: 66.4wt%; Al: 0.5wt%; Cu: 0.1wt%; B: 1.0wt%.

[0044] Put the prepared mixture into a vacuum quick-setting casting furnace, vacuumize to 1Pa, fill it with argon protection for heating and melting, and then pour the melted liquid on the rotating cooling copper roller to obtain a thickness of about 0.3mm NdFeB alloy cast sheet.

[0045] Hydrogen crushing of NdFeB alloy castings to obtain NdFeB coarse powder, mix NdFeB coarse powder with antioxidant and lubricant for 1 hour, and then obtain NdFeB fine powder with an average particle size D50 of 3.04 μm by jet mill . Mix tungsten powder, Cu-Ga alloy and NdFeB fine powder according to the volume ratio of 0.5:0.5:100 for 1.5h to obtain mixed powder; wherein, the average particle diameter D50 of tungsten powder is 500nm, and the average particle size of Cu-Ga alloy The particle size D50 is 1.3 μm, and the Ga content in the Cu-Ga alloy is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com