Automatic production line for assembling tensioners

An automatic production line and tensioner technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, high labor cost, high labor intensity, etc., and achieve simple process, fast conveying efficiency, and assembly accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

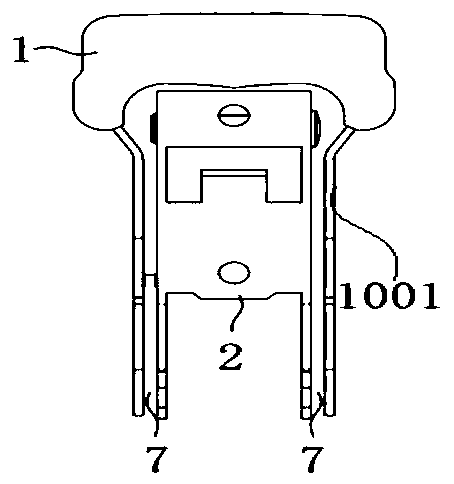

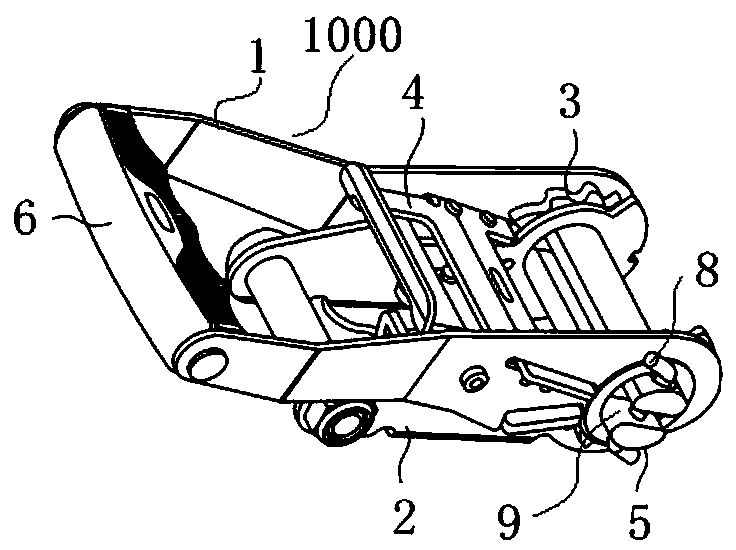

[0094] The automatic production line of the assembly tensioner of the present embodiment, as figure 1 , 2 As shown, a ratchet 3 is vertically assembled at the ratchet assembly position 7 on both sides of the tensioner 1001 to be assembled symmetrically, and a pair of ratchet half shafts 5 are assembled horizontally at the ring centers of the two ratchet 3, and then the ratchet half shaft 5 Connected by the vertical shaft pin 8, and then assembled into a tensioner finished product 1000, such as Figure 4 As shown, the entire production line includes a ratchet automatic assembly device 30, an axle automatic assembly device 50, a shaft pin automatic assembly device 60, and a transmission track 35 that transports the tensioner 1001 to be assembled between each process. On the 35th, the ratchet automatic assembly, the wheel axle automatic assembly and the pivot pin automatic assembly are completed successively.

[0095] like Figure 5 As shown, the ratchet automatic assembly de...

Embodiment 2

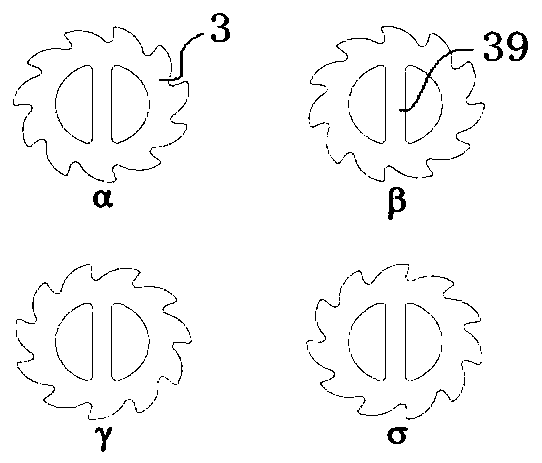

[0109] The automatic production line of the assembly tensioner in the present embodiment is further improved on the basis of embodiment 1, as Figure 11 As shown, the ratchet input mechanism 31 includes: a ratchet input unit 311, which is used to input the ratchet 3 on the same plane to the beginning of the steering track 312; a ratchet axial adjustment unit 313, which is arranged on the steering track 312, for on the same side of the ratchet 3 that will be entered as image 3 The shown ratchet shaft 39 is adjusted to the same axis; the ratchet tooth direction adjustment unit 314 is arranged on the direction adjustment track 312 and is used to adjust the ratchet teeth of the coaxial ratchet 3 to the same tooth direction; the output unit 315 is its Located at the end of the steering track 312, it is used to output the coaxial and toothed ratchets 3; the transmission mechanism 316 is used to sequentially transmit the ratchets 3 on the steering track 312 to each unit;

[0110] In...

Embodiment 3

[0126] The automatic production line of the assembly tensioner in the present embodiment is further improved on the basis of embodiment 2, as Figure 8 , Figure 9 and Figure 10 As shown, the ratchet input unit 311 includes: a vibrating plate 1 310; a screening track 3111, one end of which is fixedly connected to the outlet of the hopper at the top of the vibrating plate 310, and a screening hole 3110 is opened on it; an input track 3112, which is fixedly connected At the other end of the screening track 3111 and connected with the steering track 312;

[0127] like Image 6 As shown, it also includes a linear vibration feeder 3113, which is fixedly connected with the input track 3112, and feeds the ratchet 3 on the input track 3112; when the ratchet 3 on the setting surface passes through the screening hole 3110, it turns over and falls into the vibration plate 1 310 The vibrating plate 310 is a commonly used feeding device in the field of material transmission, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com