Body height control method for pipe rack inspection robot

A technology for inspection robots and pipe galleries, applied to manipulators, program-controlled manipulators, manufacturing tools, etc., to achieve the effect of shortening inspection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

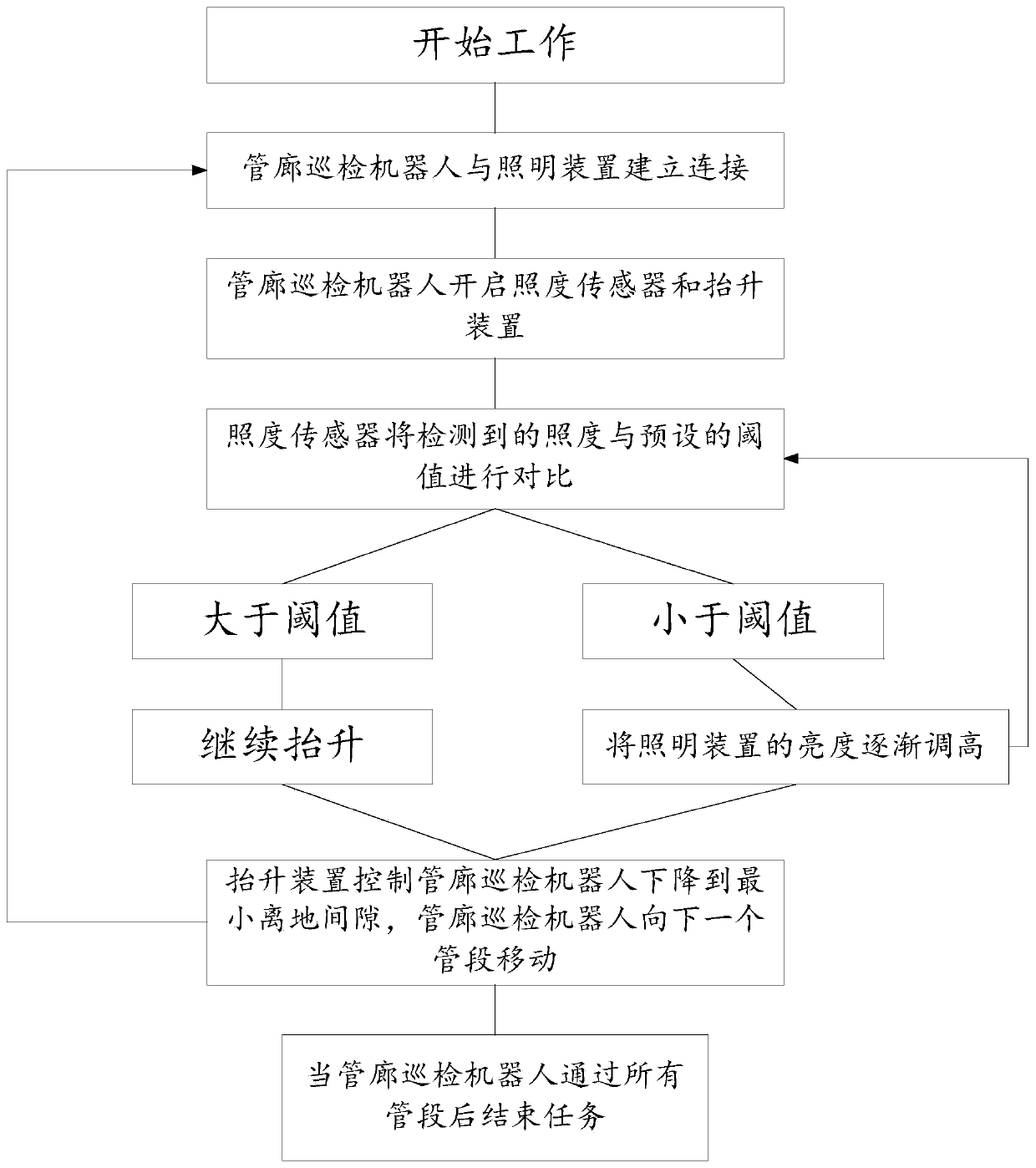

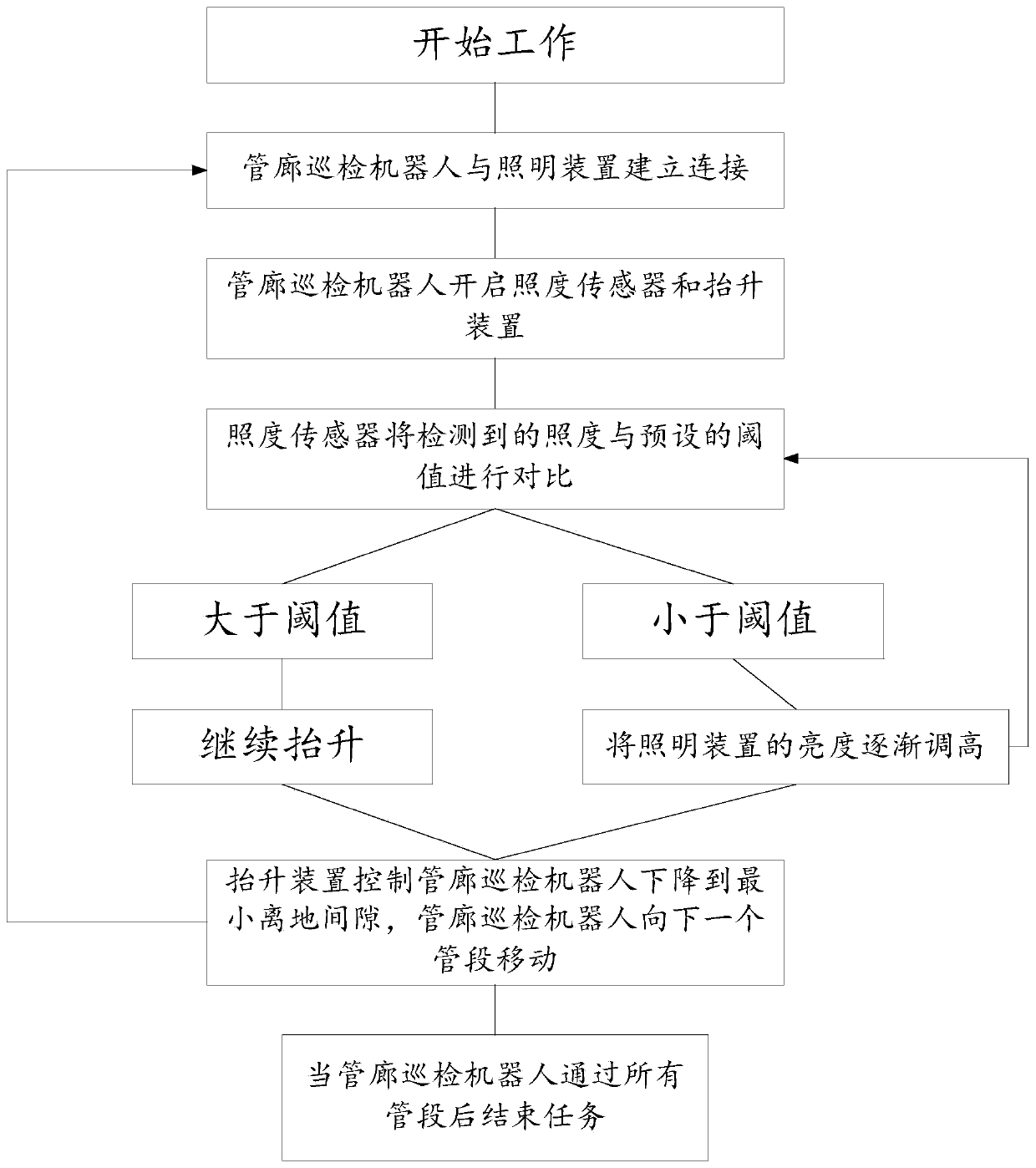

[0029] A method for controlling the height of a pipe gallery inspection robot, comprising a pipe gallery inspection robot with an illuminance sensor, the pipe gallery inspection robot is also provided with a lifting device, and the lifting device is used to adjust the height of the pipe gallery inspection robot Ground clearance, the inspection robot of the pipe gallery and the lighting device in the pipe gallery are equipped with wireless communication devices, and the lighting device is matched with the wireless communication device one by one, and the following steps are also included:

[0030] S1. The pipe gallery inspection robot enters the pipe gallery and starts working;

[0031] S2. The pipe gallery inspection robot stops moving after entering the pipe section where the first lighting device is located, and the wireless communication device of the pipe gallery inspection robot establishes a connection with the wireless communication device of the first lighting device; ...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the wireless communication device uses NFC technology for communication. NFC is an emerging technology. Devices using NFC technology can exchange data when they are close to each other. It is evolved from the integration of non-contact radio frequency identification RFID and interconnection technology. By integrating sensing on a single chip With the functions of type card reader, inductive card and point-to-point communication, mobile terminals are used to realize applications such as mobile payment, electronic ticketing, access control, mobile identification, and anti-counterfeiting.

[0040] Further, in the step S6, the pipe gallery inspection robot moves to the next pipe section, and disconnects from the wireless communication device of the previous pipe section after entering the next pipe section. After the corridor inspection robot is disconnected, adjust the brightness of the lighting device connect...

Embodiment 3

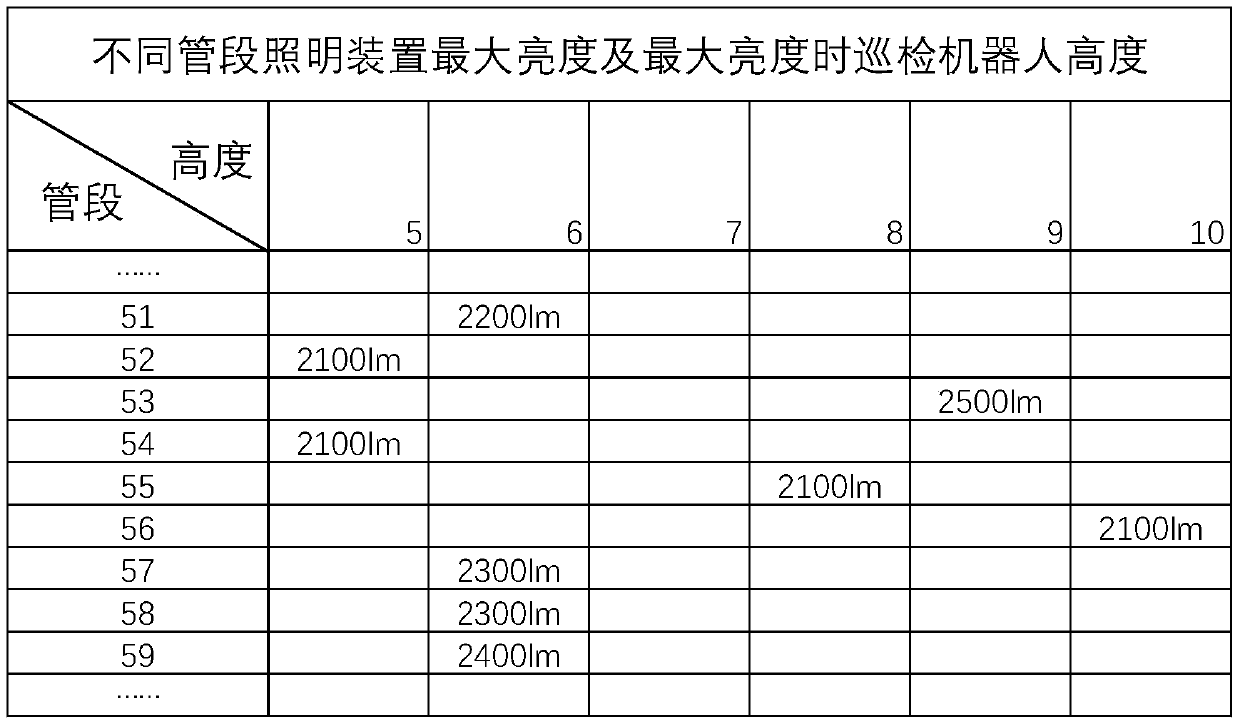

[0045] A kind of data tested in actual work, the illuminance is 0.2lx when the minimum illuminance of all lighting devices is adjusted, and the illuminance threshold detected by the illuminance sensor is 100lx, as shown in Table 1, this device has been used in multiple Different illuminance adjustments are made at heights.

[0046] Table 1: The maximum brightness of different pipe section lighting devices and the height of the inspection robot at the maximum brightness

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com