Excimer lamp

An excimer lamp and a part of the technology, applied in the field of excimer lamps, can solve the problems of changes in processing capacity of excimer lamps and reduction of illuminance maintenance rate, and achieve the effect of maintaining illuminance and suppressing the degree of illuminance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

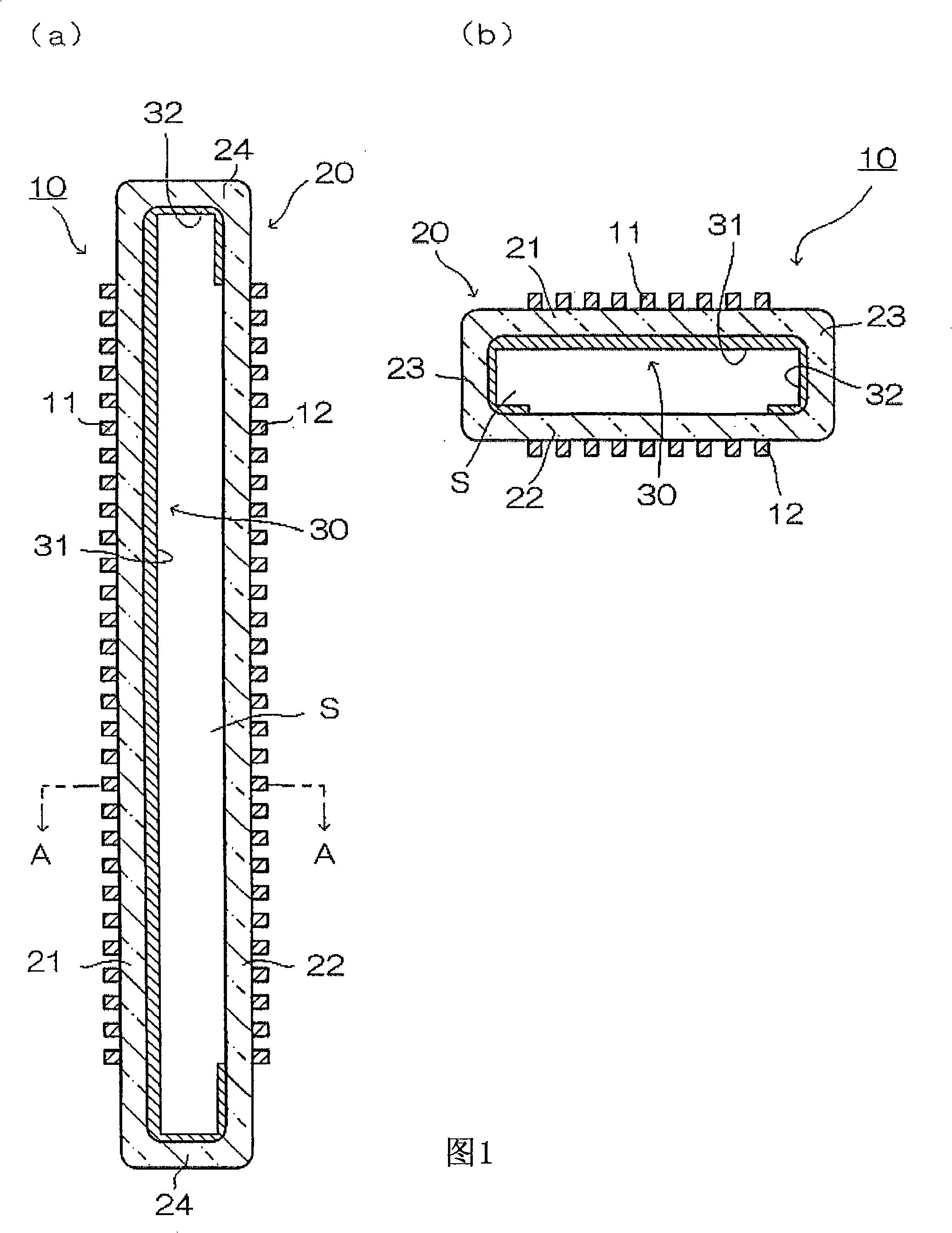

[0032] figure 1 It is an explanatory cross-sectional view showing a schematic configuration of an example of the excimer lamp 10 of the present invention. figure 1 (a) is a sectional view showing a section along the longitudinal direction of the discharge vessel 20, figure 1 (b) means figure 1 (a) Cross-sectional view of A-A' line.

[0033] The excimer lamp 10 includes a hollow long discharge vessel 20 having a rectangular cross-section whose both ends are hermetically sealed and a discharge space S is formed inside. This discharge vessel 20 comprises: an upper wall plate 21 and a lower wall plate 22 relative to the upper wall plate 21; a pair of side wall plates 23 connected to the upper wall plate 21 and the lower wall plate 22; and will be composed of these upper wall plates 21, A pair of end wall plates 24 that are sealed at both ends of the square cylindrical body formed by the lower wall plate 22 and the pair of side wall plates 23 . The discharge vessel 20 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com