Light transmissive material and lamp, and gas treating device and gas treating method

A technology of gas treatment and light transmission, which is applied in the direction of gas treatment, separation methods, gas discharge lamps, etc., can solve the problems of ultraviolet illuminance reduction, illuminance reduction, etc., and achieve the effect of suppressing the reduction of illuminance and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

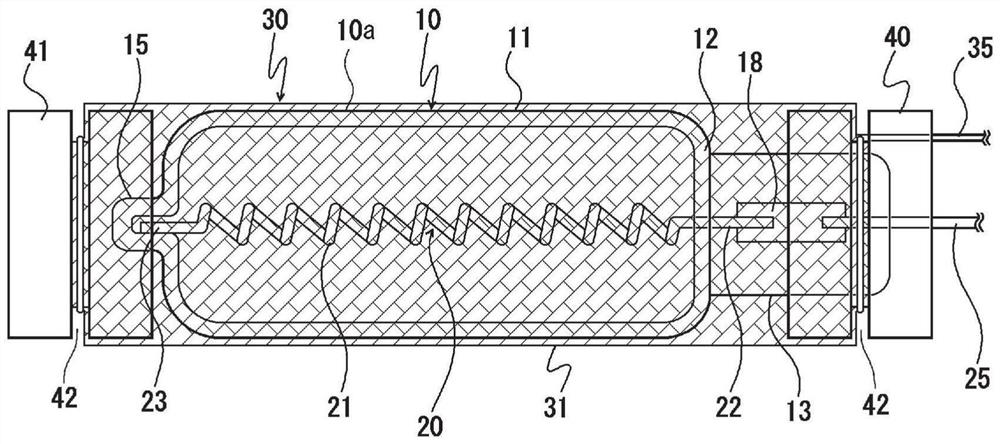

[0115] according to figure 1 With the structure, excimer discharge lamps with the following specifications were manufactured.

[0116] Light-emitting tube (10):

[0117] Material of glass substrate = silica glass

[0118] The material of the surface layer = nano-silica particles with an average particle size of 10nm

[0119] The outer diameter of the light emitting part (11) = 16mm

[0120] The inner diameter of the light emitting part (11) = 14mm

[0121] The length of the light emitting part (11) = 130mm

[0122] Inner electrode (20):

[0123] Material = Tungsten

[0124] Single wire diameter = 0.3mm

[0125] Outer electrode (30):

[0126] Material = stainless steel (SUS304)

[0127] Single wire diameter = 0.2mm

[0128] Enclosed gas:

[0129] Gas Type: Xenon

[0130] Enclosed pressure: 20kPa

[0131] Rated voltage: 4kV

[0132] In the above, the surface layer in the arc tube is formed as follows.

[0133] Inner diameter is 90mm, length is the cylindrical cont...

Embodiment 2

[0136] An excimer discharge lamp having the same specifications as in Example 1 was produced except that nano-silica particles having an average particle diameter of 50 nm were used as nano-silica particles.

[0137] The surface roughness Ra of the outer surface of the arc tube was measured in the same manner as in Example 1 and found to be 12.1 nm.

Embodiment 3

[0139] An excimer discharge lamp having the same specifications as in Example 1 was produced except that the surface layer in the arc tube was formed as follows.

[0140] By immersion method, the dispersion liquid that the average particle diameter is 10nm nano-silica particles is dispersed in the ratio of 30% by mass is applied to the outer surface of the glass substrate that constitutes the arc tube, and left to dry for 72 hours. This forms a skin on the outer surface of the glass substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com