Preparation method of thermally reversible color-changing composites based on polydiacetylene and metal-organic framework compounds

A technology of metal-organic framework and composite materials, which is applied in the field of preparation of thermally reversible discoloration materials, can solve the problems that sensors cannot be reused and have little practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

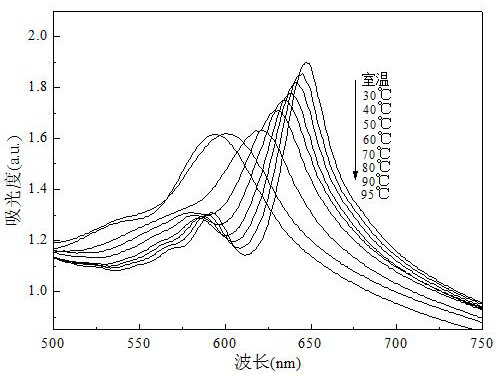

[0016] Example 1. Preparation and performance of poly(PCDA) / MOF-177 composite material

[0017] (1) Preparation of poly(PCDA) / MOF-177 composites

[0018] Weigh 0.475 g Zn(NO 3 ) 2 ·6H 2 O and 0.095 g H 3 Add 30 mL of DMF to BTB in a beaker, stir at room temperature for 30 min, the solution turns slightly yellow after being completely dissolved; pour the mixed solution into a 50 mL polytetrafluoroethylene reactor, degas under vacuum for 20 min, and release the gas. After 3 consecutive times, the reaction kettle was gently placed in an oven and reacted at 85°C for 48 h; at the end of the reaction, light yellow crystals were precipitated, filtered with suction, washed with a small amount of DMF ultrasonically for 3 times, and dried in vacuum at 65°C for 24 h. Obtained 0.144g MOF-177;

[0019] Weigh 8 mg of purified 10,12-pentacosadiynoic acid (PCDA), dissolve it in 3 mL of dimethyl sulfoxide, add 7 mL of deionized water to obtain PCDA solution; take 3 mg of MOF-177, Dispers...

Embodiment 2

[0022] Example 2. Preparation and reversible thermochromic properties of poly(TCDA) / MOF-177 composites

[0023] (1) Preparation of poly(TCDA) / MOF-177 composites

[0024] Weigh 8 mg of purified 10,12-trisosadiynoic acid (TCDA), dissolve it in 3 mL of dimethyl sulfoxide, add 7 mL of deionized water to obtain TCDA solution; take 3 mg of MOF-177, Disperse in 10 mL deionized water to obtain MOF-177 solution; then mix TCDA solution and MOF-177 solution, sonicate at 65-80°C for 30-60 min, cool to room temperature, and stand at low temperature for 10-16 h to obtain white suspension; it was irradiated and polymerized under ultraviolet light with a wavelength of 254 nm for 10 min to obtain a blue suspension—poly(TCDA) / MOF-177.

[0025] The test results of reversible thermochromic properties show that poly(TCDA) / MOF-177 has similar thermal reversible discoloration properties as poly(PCDA) / MOF-177.

Embodiment 3

[0026] Example 3. Preparation and reversible thermochromic properties of poly(HDDA) / MOF-177 composites

[0027] (1) Preparation of poly(HDDA) / MOF-177 composites

[0028] Weigh 8 mg of purified 5,7-hexadecadiynoic acid (HDDA), dissolve it in 4 mL of dimethyl sulfoxide, add 6 mL of deionized water to obtain HDDA solution; take 3 mg of MOF-177, and disperse in 10 mL of deionized water to obtain MOF-177 solution; then mix HDDA solution and MOF-177 solution, sonicate at 65-80°C for 30-60 min, cool to room temperature, and stand at low temperature for 10-16 hours to obtain a white suspension; It was irradiated and polymerized under ultraviolet light with a wavelength of 254 nm for 10 min to obtain a blue suspension—poly(HDDA) / MOF-177.

[0029] The test results of reversible thermochromic properties show that poly(HDDA) / MOF-177 and poly(PCDA) / MOF-177 have similar thermally reversible discoloration properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com