Bearing assembly dimensional stability control method

A technology of dimensional stability and bearing components, which is applied in the field of bearing manufacturing, can solve the problems that the residual stress and structural stability of bearing components affect the bearing life, affect the dimensional accuracy and life of the bearing, and cannot be effectively solved, achieving significant practical application value , Improve organizational stability, and ease of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

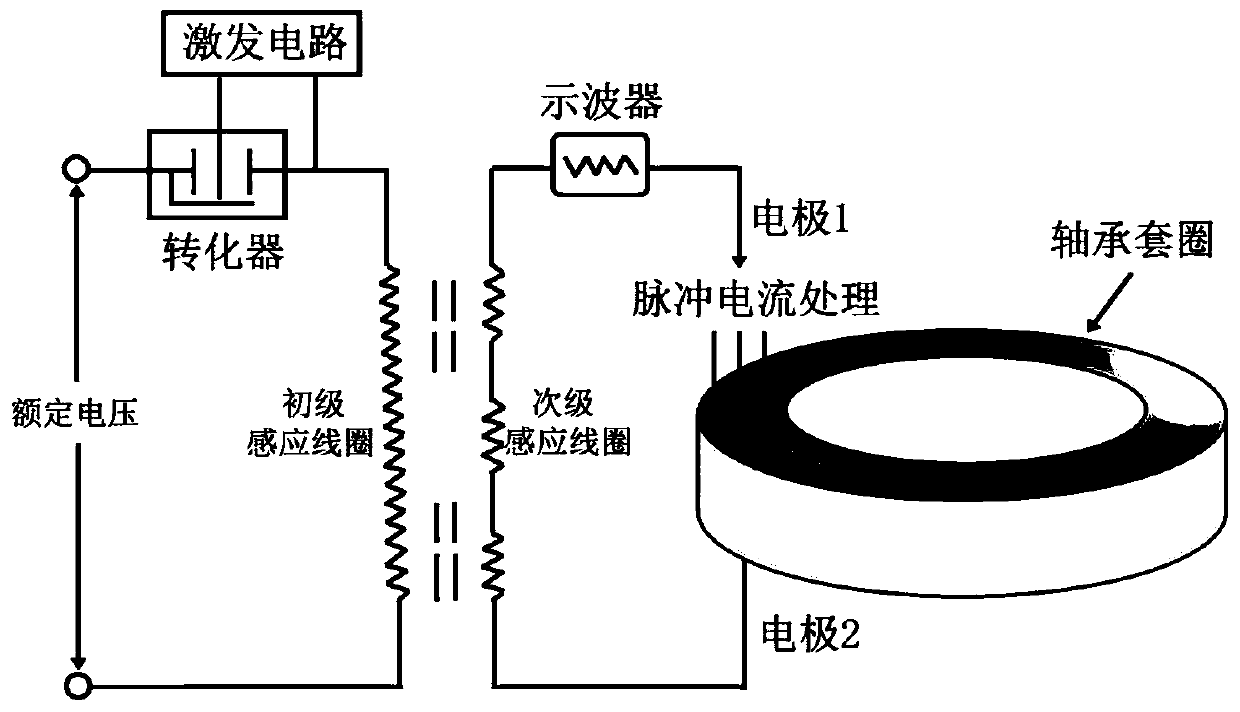

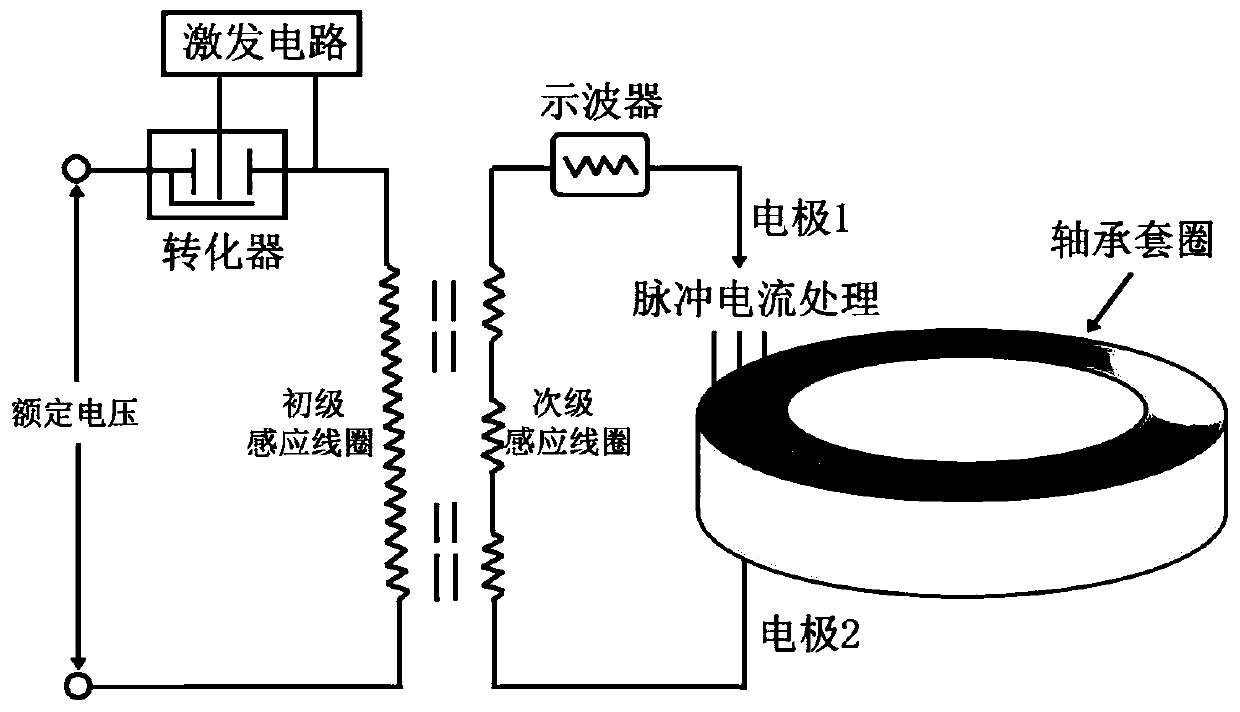

[0033] Taking a quenched and tempered bearing ring of a certain type made of GCr15 as an example, the dimensional stability control method is realized according to the following steps:

[0034] S1. Grind and polish the upper and lower end surfaces of the GCr15 bearing ring after quenching and tempering, and then clamp the bearing ring in the middle of the copper electrode rod of the pulse current generator, so that the upper and lower end surfaces are in contact with the two electrode rods;

[0035] S2. Divide the bearing ring into 8 areas along the circumferential direction, and set the pulse current density to 5kA / cm 2 , the action time of a single pulse current is 0.02s, and the number of electric pulses in a continuous pulse current treatment is 6. The continuous pulse current treatment is performed on the bearing ring. After a continuous pulse current treatment is completed, continue after a gap of 5s Perform the next continuous pulse current treatment on the same partiti...

Embodiment 2

[0040] Taking the quenched and tempered bearing ring of a certain type of M50 material as an example, the dimensional stability control method is realized by the following steps:

[0041] S1. Grind and polish the upper and lower end surfaces of the M50 bearing ring after quenching and tempering, and then clamp the bearing ring in the middle of the copper electrode rod of the pulse current generator, so that the upper and lower end surfaces are in contact with the two electrode rods;

[0042] S2. Divide the bearing ring into 32 areas along the circumferential direction, and set the pulse current density to 12kA / cm 2 , the action time of a single pulse current is 0.02s, and the number of electric pulses in one continuous pulse current treatment is 12. Continuous pulse current treatment is performed on the bearing ring. Perform the next continuous pulse current treatment on the same partition of the bearing ring, and perform 8 consecutive pulse current treatments on the same part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com