Pulp block removal equipment for tow used in chemical fiber spinning production

A pulp block and tow technology is applied in the field of pulp block removal equipment for tow used in chemical fiber spinning production, and can solve the problems of low efficiency, difficult treatment, and influence on pulp block removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

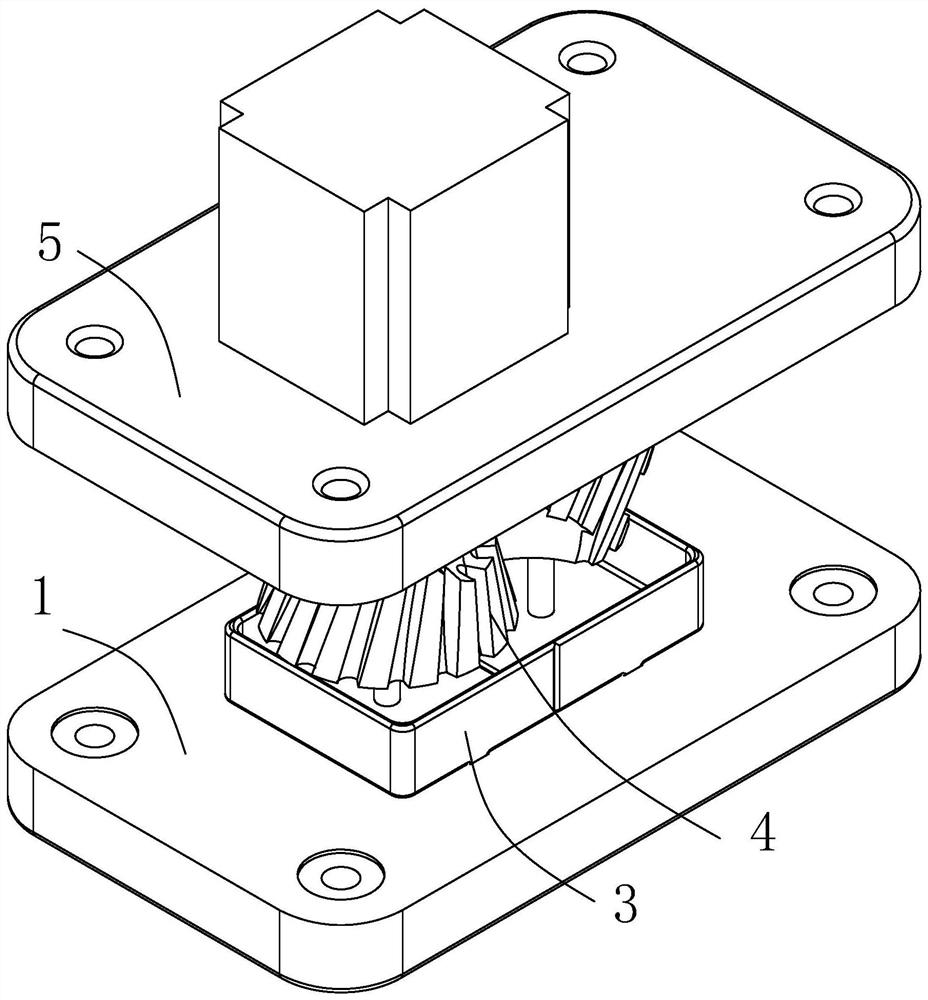

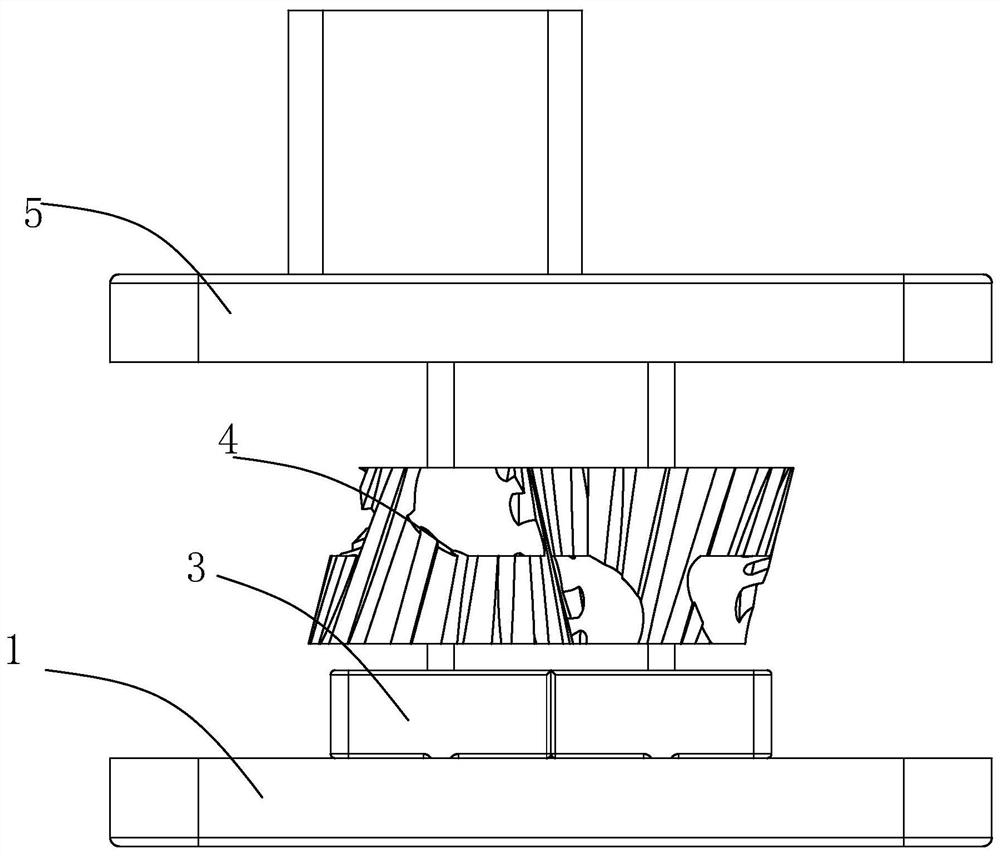

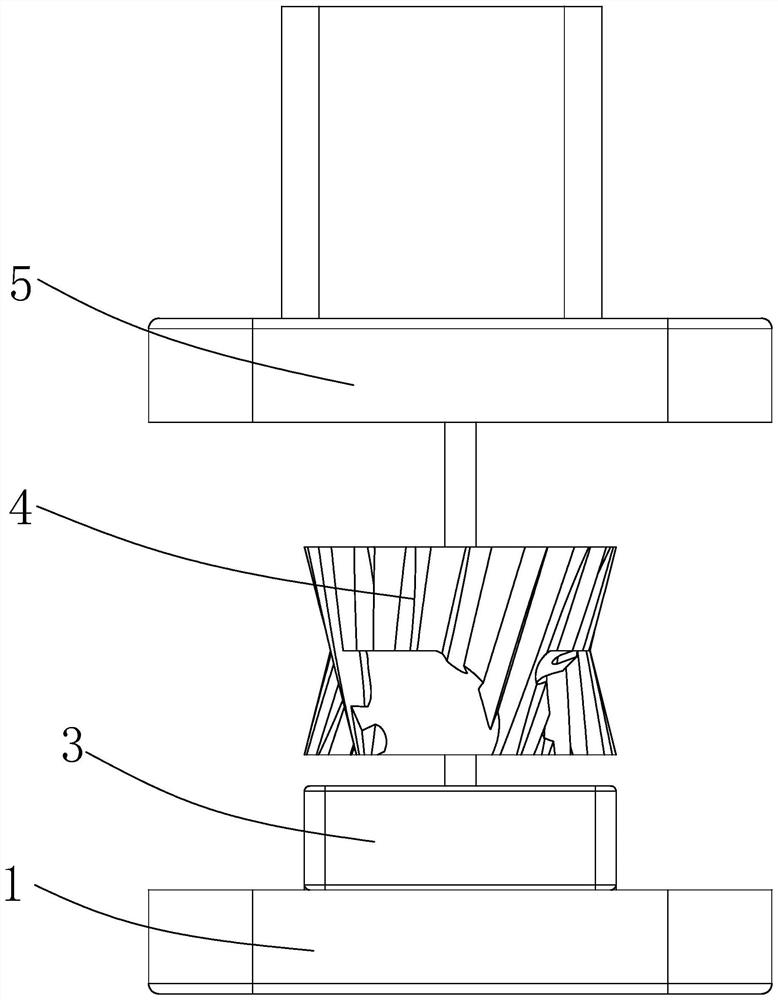

[0037] Such as Figure 1-8 As shown, the present invention provides a technical solution: a slurry block removal device for a filament beam of a chemical fiber spinning, including mounting plate A1, two mounting grooves 2, collecting device 3, slurry block removal device 4, and mounting plate B5. The two mounting grooves 2 are symmetrically opened on the upper surface of the mounting plate A1, and the bottom portion of the collecting device 3 is connected between the mounting groove 2, and the slurry block removal device 4 is disposed between the mounting plate B5 and the collecting device 3, the mounting plate A1 is installed. On the winding machine, and, the removal is performed by the slurry block removal device 4, and the collection of the selection device 3 can be achieved, and the four angles of the mounting plate A1 and the mounting plate B5 can be installed. The bolt slot 6 is used for easy installation operation.

[0038] The collecting device 3 includes two collecting cas...

Embodiment 2

[0041] Such as Figure 1-8 As shown, in the basis of the first example, the present invention provides a technical solution: there is a spacing between the two cone braking heads 403, and its spacing ensures normal movement of the wire beam, and it is not easy to break the wire beam, which is easy to break The removal of a slurry block is performed.

Embodiment 3

[0043] Such as Figure 1-8As shown in the basis of the first embodiment, the present invention provides a technical solution: the number of recessed portions 404 is six, and three recessed portions 404 are group, each set of three recesses 404. Symmetrical setting with the central axis of the taper tooth grinding head 403.

[0044] The vertical depth of the recessed portion 404 is slightly less than one-half of the height of the cone joining head 403, ensuring that the steering beam located at the center can be taken out to remove the slurry block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com