On-board wet spraying manipulator system and use method thereof

A technology of manipulator and wet spraying, which is applied in the fields of construction, building structure, and building materials processing. It can solve the problems of large arm drive cylinder and forearm drive cylinder with large force, inability to realize 360-degree rotating spray, insufficient degree of freedom, etc. problems, to achieve stable and reliable support and transmission, reduce strength requirements, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

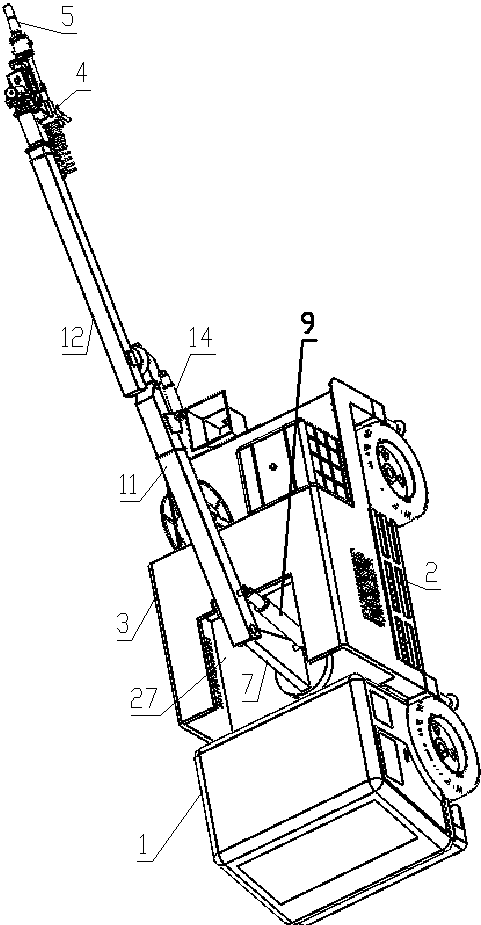

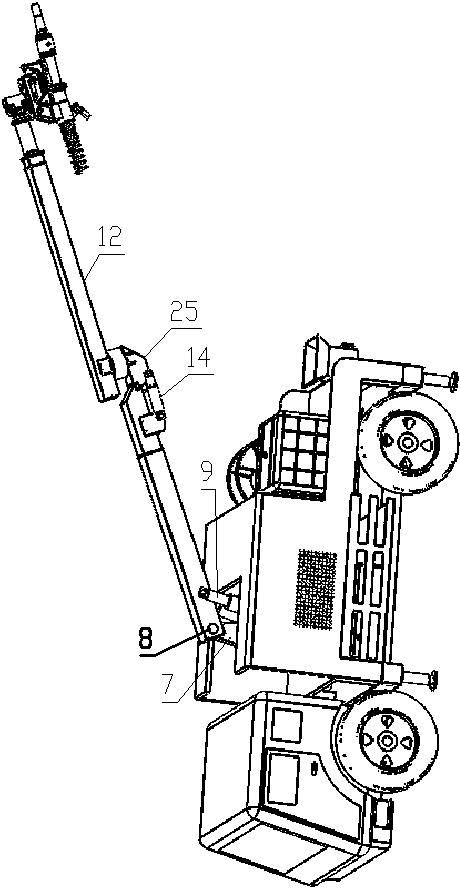

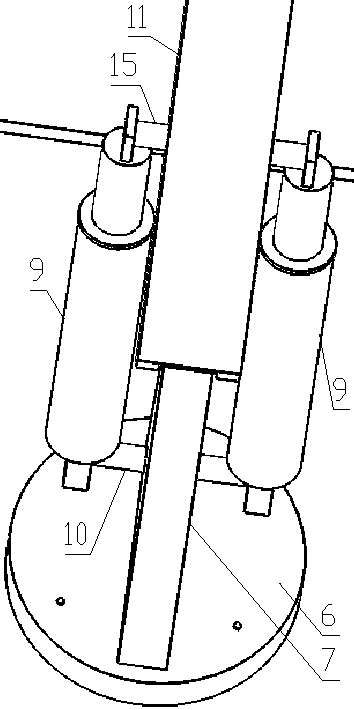

[0050] like Figure 1 to Figure 6 As shown, the vehicle-mounted wet spray manipulator system of the present invention comprises a transport vehicle 1, a frame 3 is provided on the base plate 2 of the transport vehicle 1, and a cantilever mechanism, a stirring mechanism, a conveying mechanism and a spray mechanism 4 are provided on the frame 3, and the spray mechanism 4 includes a nozzle 5 for spraying concrete slurry; the direction in which the transport vehicle 1 travels forward is the forward direction;

[0051] The stirring mechanism includes a stirring device and a slurry storage container connected with the stirring device;

[0052] The conveying mechanism includes a concrete pump 16, a slurry delivery hose, an air compressor 17, an accelerator storage container and a suction pump 18 for conveying the accelerator;

[0053] The inlet of the concrete pump 16 is connected with the slurry storage container, and the outlet of the concrete pump 16 is connected with the slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com