Steel structure plant adapting to terrain

A technology for steel structures and workshops, applied in building components, building structures, floor slabs, etc., can solve the problems of prolonged construction period of workshops, consumption of large financial and material resources, and unfavorable rapid construction and commissioning of workshops, so as to shorten construction costs and reduce dust pollution. , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

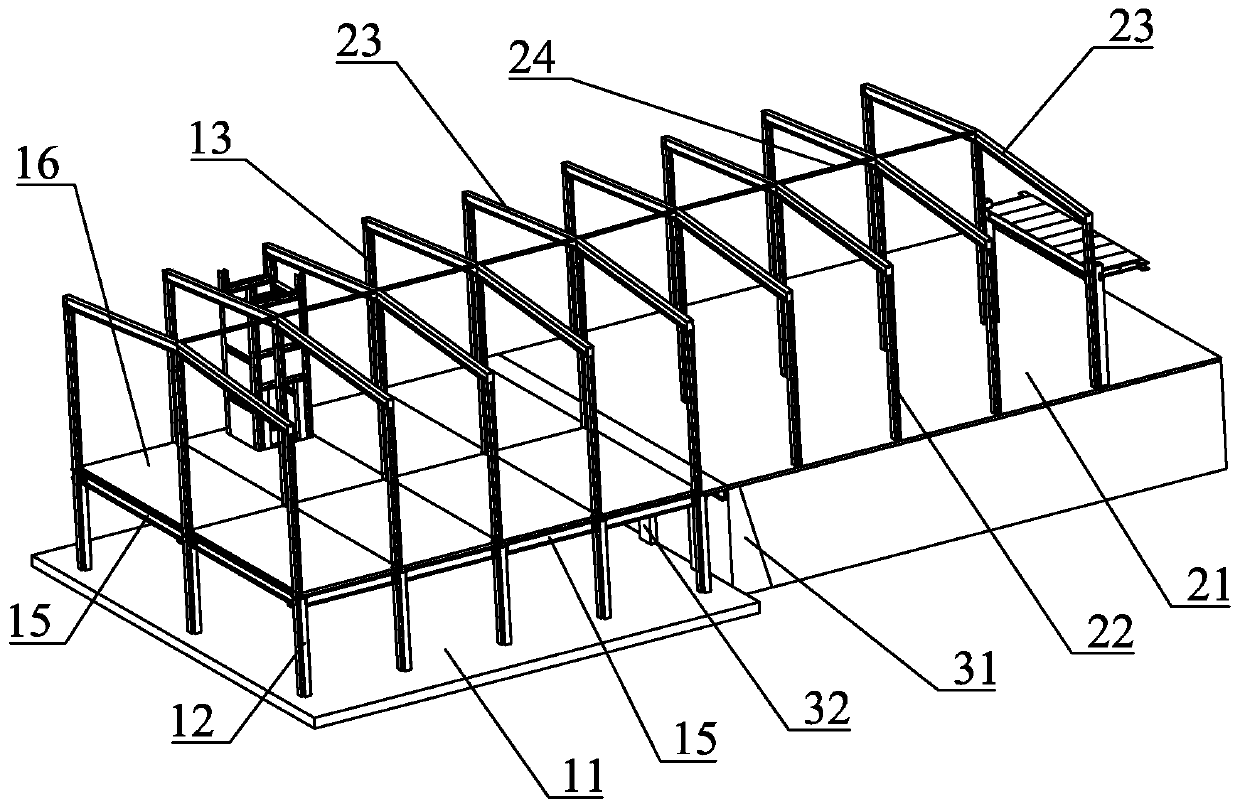

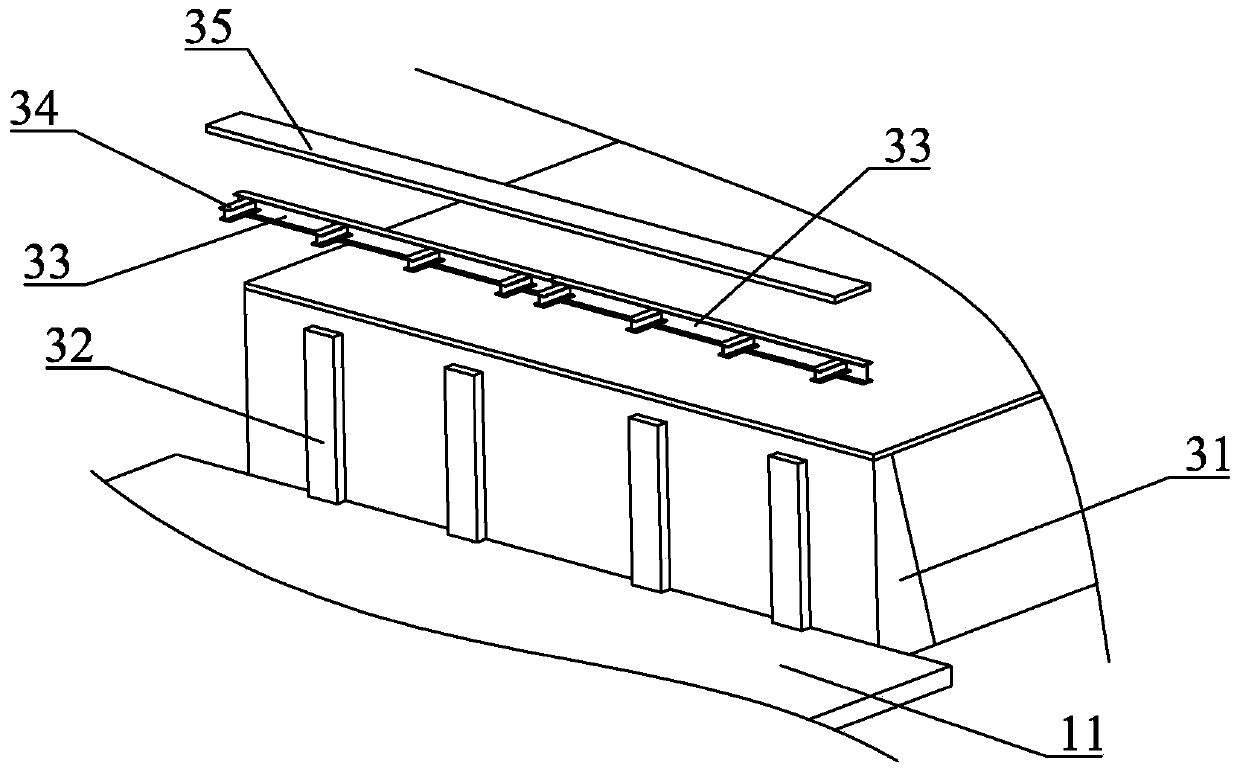

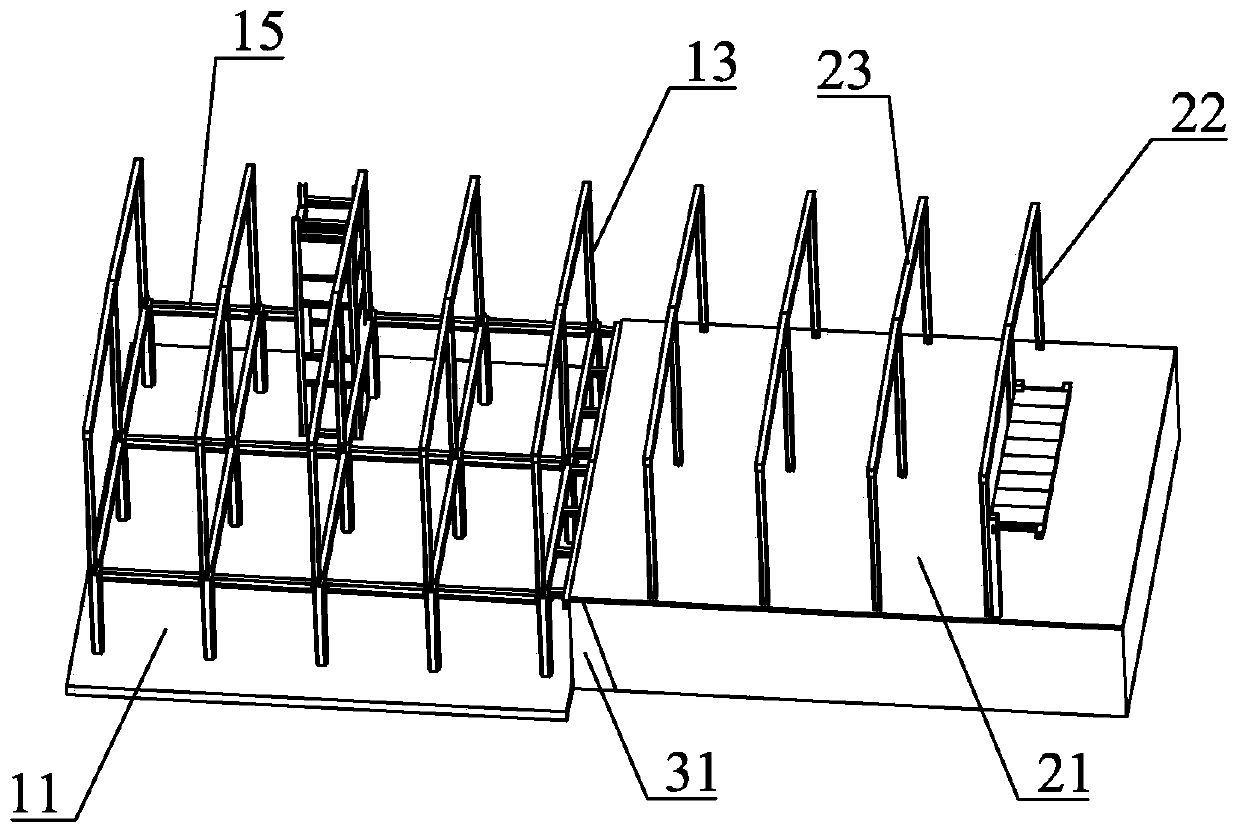

[0053] Such as Figure 1 to Figure 23 As shown, it is a steel structure factory building adapted to the terrain according to the present invention, which includes the first building body built in the flat area, the second building body built in the mountainous area, and the barrier set on the section of the mountainous area. Earth wall 31; the first building body includes a first floor layer 11 arranged in a flat area, a first-floor column 12 made of steel, a second-floor column 13 and a supporting steel plate welded to the top of the first-floor column 12 14. The bottom of the second-floor column 13 is welded on the supporting steel plate 14; the upper part of the first-floor column 12 is fixedly connected with a first beam 15, and the first beam 15 is provided with a first floor 16; Described second building...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com