Clustered curing barn circulating fan variable-frequency control system

A circulating fan and frequency conversion control technology, which is applied in the field of aeronautical examination and research barns, can solve the problems of wasting electric energy, unable to adjust the air volume of tobacco leaves, increasing labor intensity and temperature control instability, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

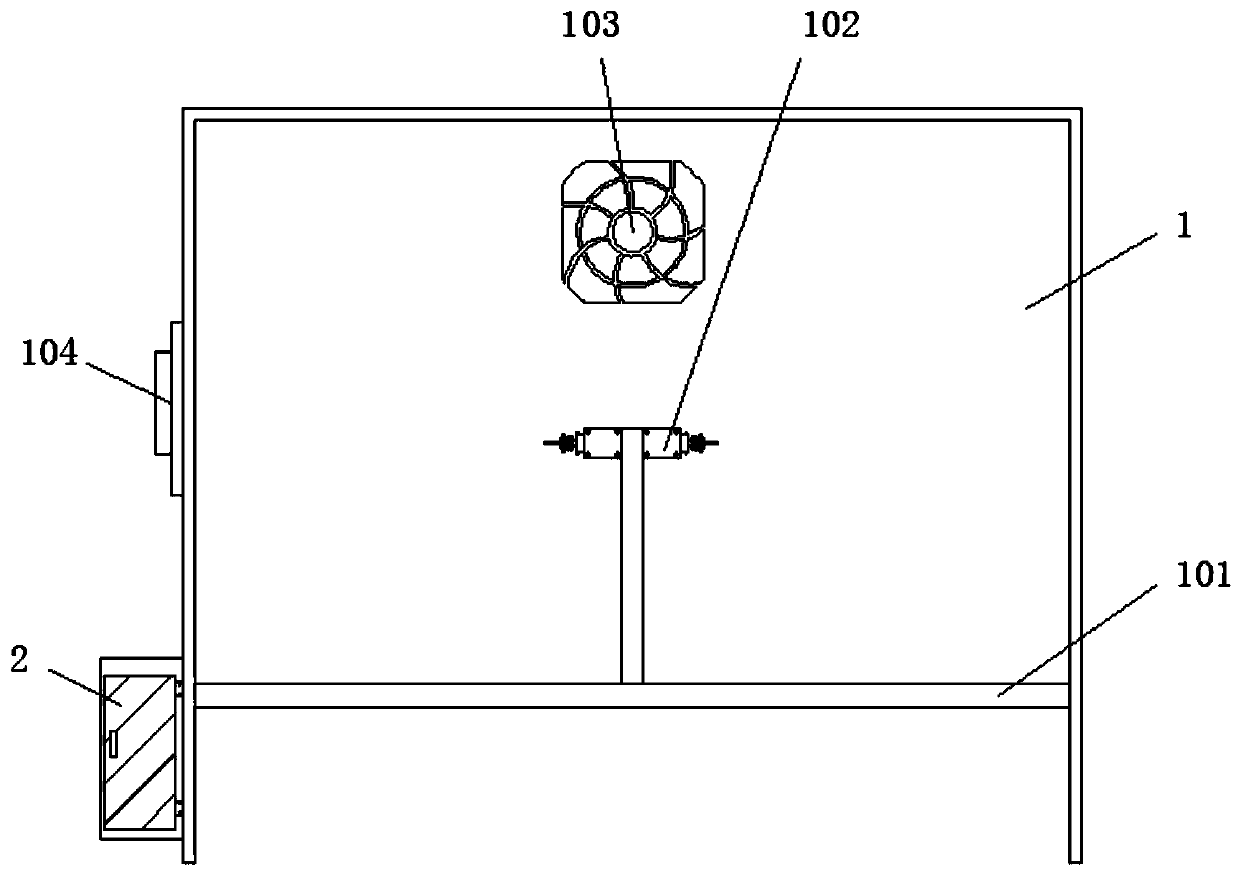

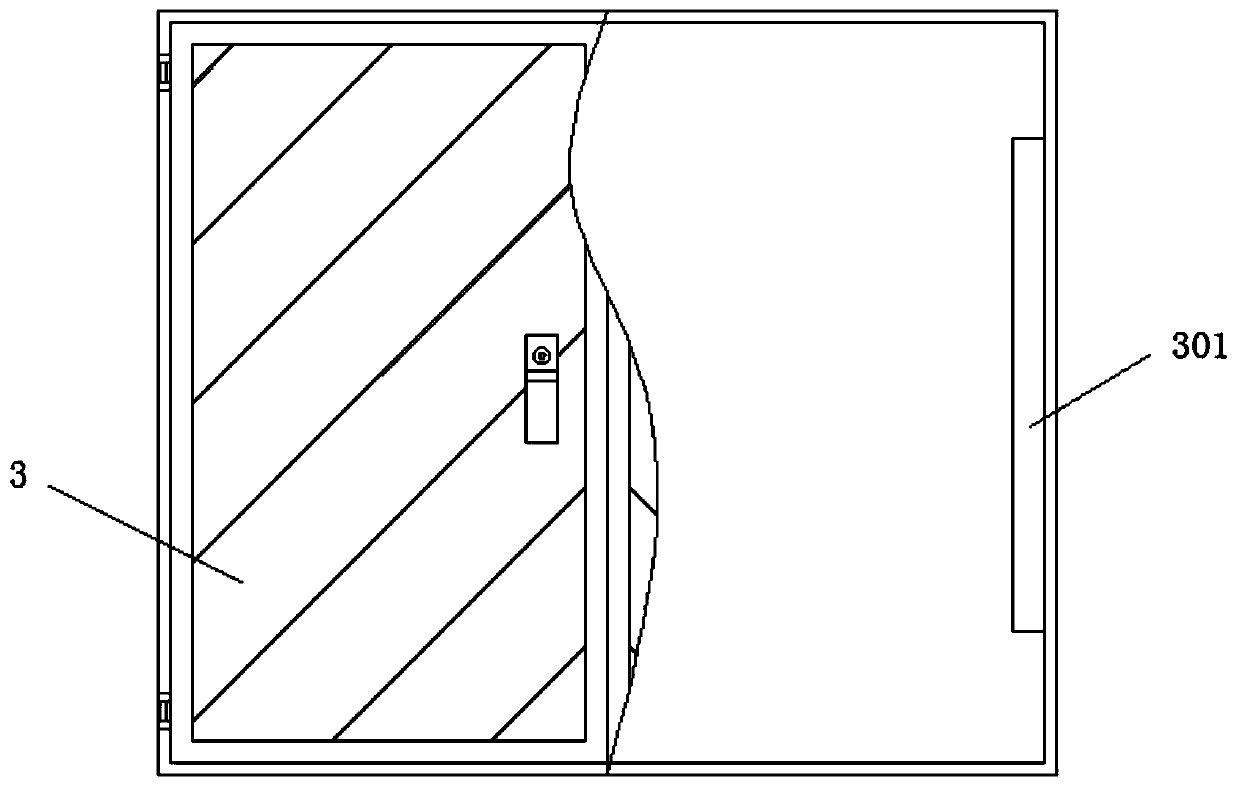

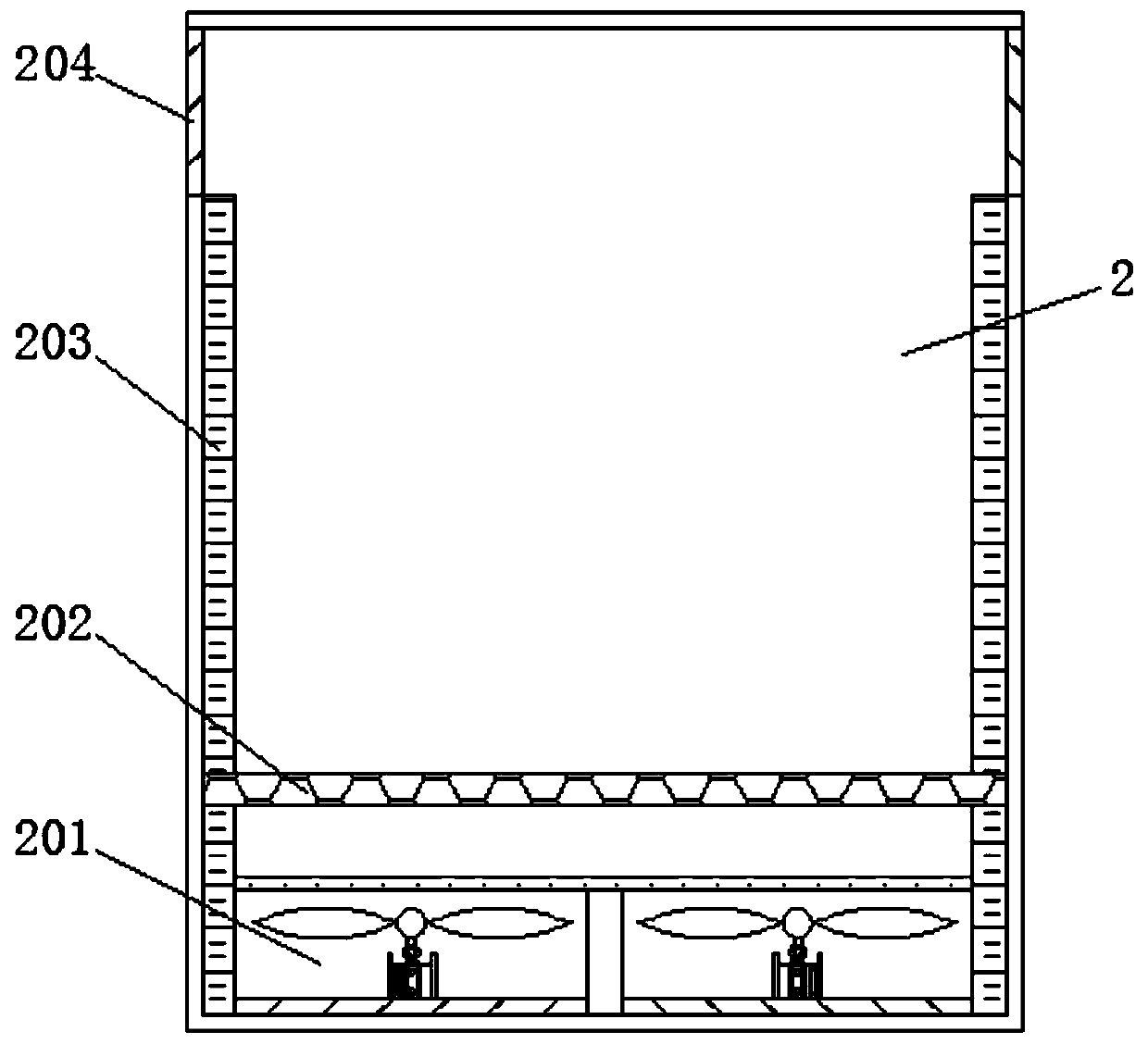

[0025] Example 1, please refer to figure 1 —4:

[0026] The baking workshop includes a cluster baking room 1, a support frame 101, a high-precision temperature probe 102, a frequency conversion fan 103, a high-precision temperature instrument 104, a control cabinet 2, a fan 201, a partition 202, an activated carbon fiber layer 203, an air outlet 204, and a machine room 3 and a display screen 301.

[0027] The inner bottom of the cluster barn 1 includes a support frame 101, and the support frame 101 and the cluster barn 1 are welded and fixed, and the two sides of the upper end of the support frame 101 are provided with high-precision temperature probes 102, and the inside of the cluster barn 1 A frequency conversion fan 103 is installed, and a high-precision temperature instrument 104 is inlaid on the outside of the cluster barn 1 .

[0028] The lower end of one side of the cluster barn 1 is connected to the control cabinet 2, and the inner bottom of the control cabinet 2 is...

Embodiment 2

[0031] Example 2, please refer to Figure 5 :

[0032] The system modules include frequency conversion control system, circulation fan frequency conversion system, circulation fan controller switching system, signal integration system, alarm system and RS485 communication technology.

[0033] Frequency conversion control system: using touch screen mode, its function is;

[0034] (1) Set the speed of the variable frequency fan at a certain temperature range;

[0035] (2) Select the control system where the circulating fan is located.

[0036] Circulation fan frequency conversion system: the temperature probe is placed near the probe of the automatic control instrument in the barn, and the probe transmits the temperature signal to the integrated control system in real time. After receiving the probe signal, the integrated control system transmits the control signal to the frequency converter according to the set speed In order to precisely control the speed of the circulating...

Embodiment 3

[0041] The specific analysis of project data is as follows:

[0042] Statistical table of power consumption for single oven baking with different treatments

[0043] deal with Power consumption (degrees) Unit price (yuan) Amount (yuan) deal with 294 0.8 235.2 Control (CK) 316 0.8 252.8

[0044] It can be seen from the "Statistical Table of Electricity Consumption for Single Oven Baking with Different Treatments" that the baking room using the frequency conversion control system saves 7% of electric energy compared with the conventional baking room, which can show that the use of the frequency conversion control system has energy-saving effects.

[0045] Quality Appraisal Table of Tobacco Leaf Appearance of Different Treatments (Middle Leaf)

[0046] deal with Maturity Oil identity structure color Chroma deal with Mature many medium loose Orange+ concentrated Control (CK) Mature Have medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com