Quasi-zero stiffness vibration isolator based on magnetic attraction component and vehicle

A quasi-zero stiffness, vibration isolator technology, applied in the direction of shock absorbers, magnetic springs, shock absorber-spring combinations, etc., can solve the problems of large reserved space, too many parts of the vibration isolator, etc., to improve reliability performance, simple structure, and the effect of improving the vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

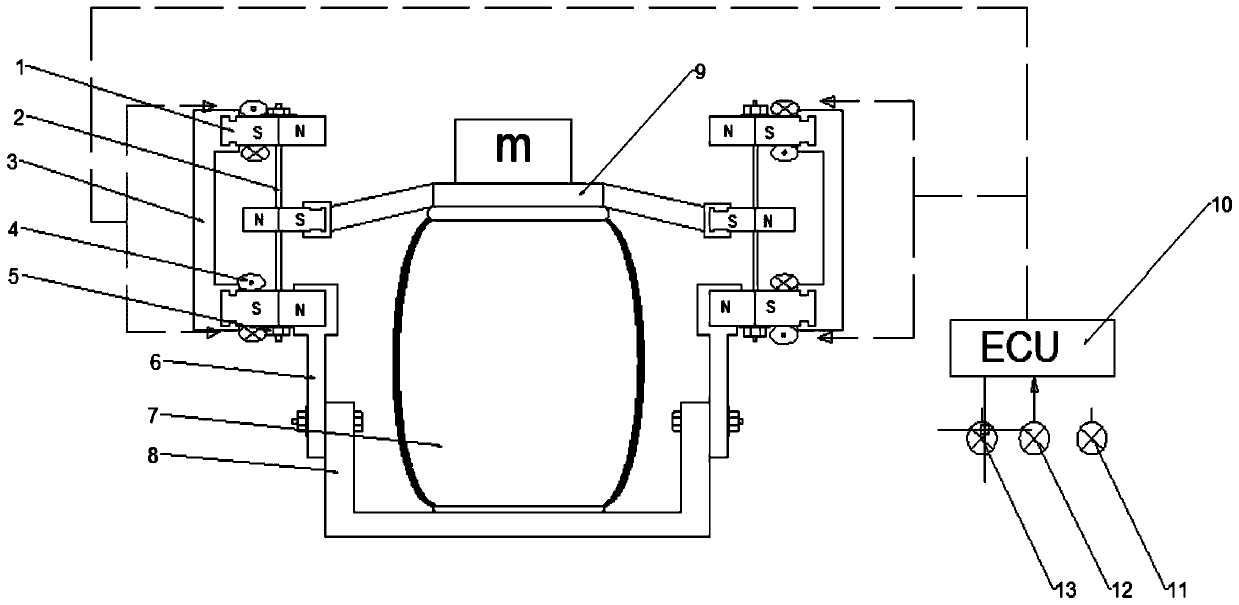

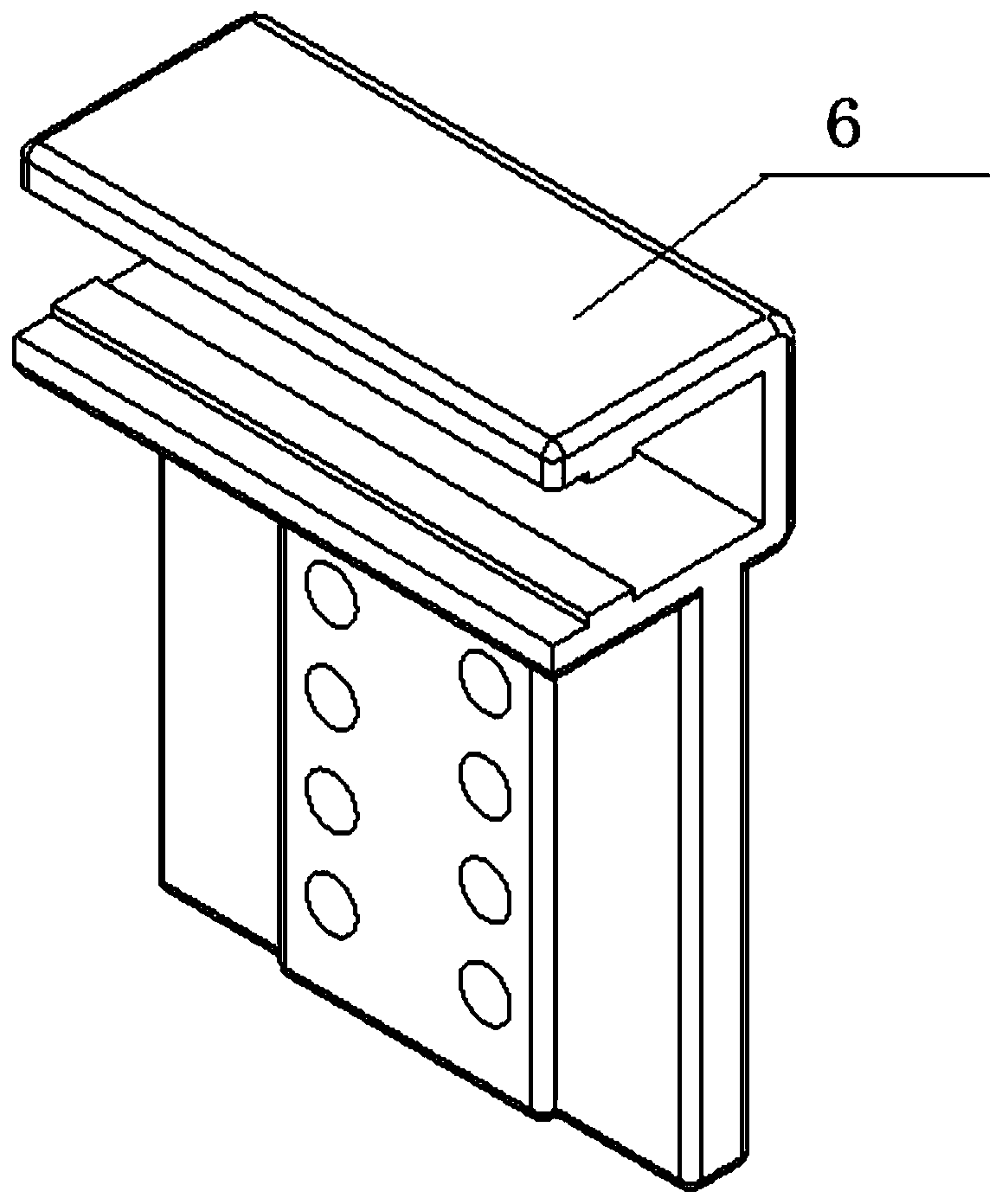

[0043] Such as figure 1 As shown, a quasi-zero stiffness vibration isolator based on magnetic attraction components, including a magnetic spring mechanism and an air spring 7;

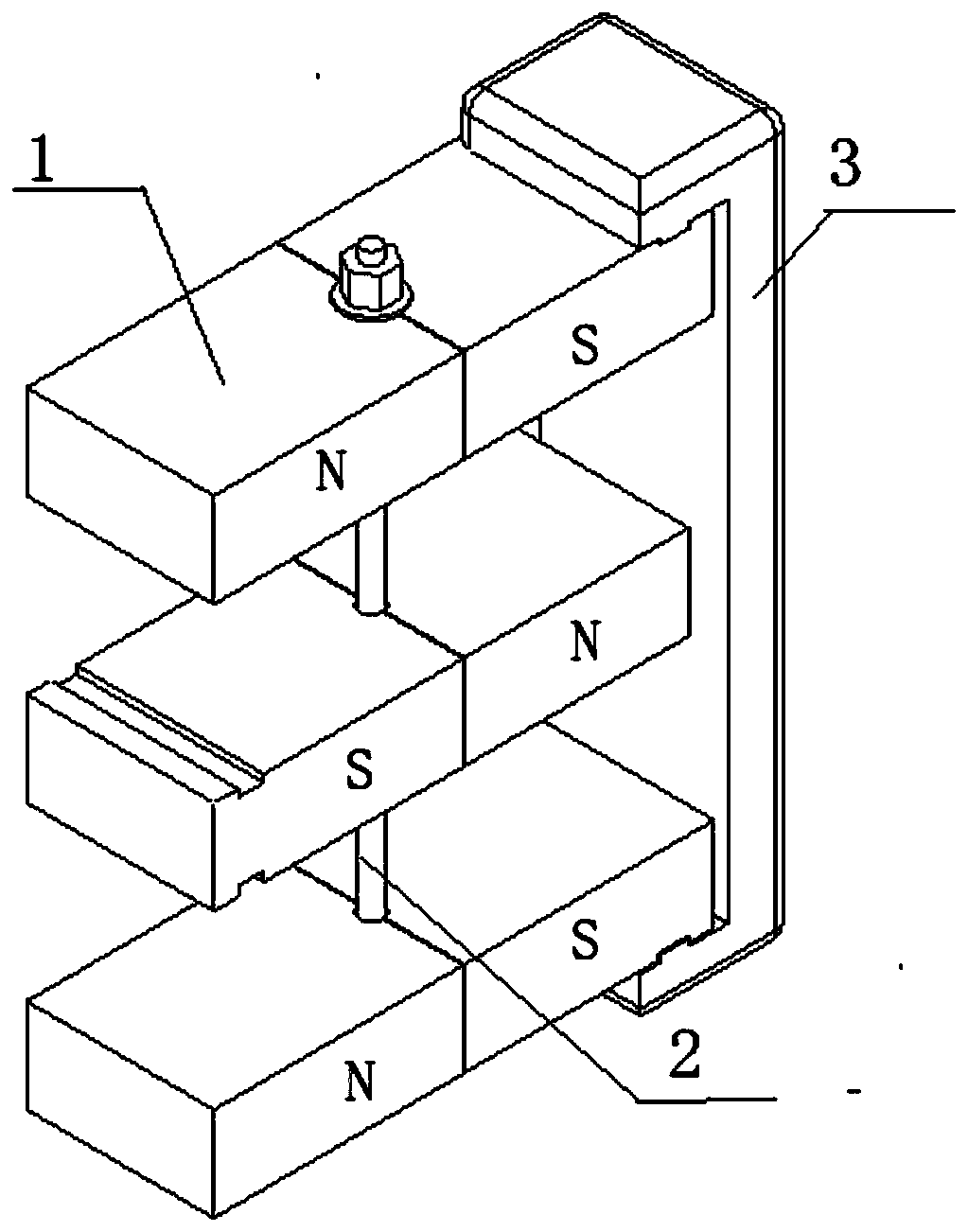

[0044] The magnetic spring mechanism is symmetrically arranged on both sides of the air spring 7 along the axis of the air spring 7; the magnetic spring mechanism includes 3n permanent magnets 1, and n is a positive integer. In this embodiment, the number of permanent magnets 1 There are 3 permanent magnets 1, and the 3 permanent magnets 1 are installed on the guide tube 2 in the longitudinal direction, and move linearly along the guide tube 2, and the adjacent permanent magnets 1 are opposite to each other at different stages; the uppermost permanent magnet 1 and the lowermost permanent magnet One end of the permanent magnet 1 is connected, the other end of the lowest permanent magnet 1 is connected with the base plate of the air spring 7 , and the middle permanent magnet 1 is connected with the upper...

Embodiment 2

[0073] A vehicle includes the quasi-zero-stiffness vibration isolator based on the magnetic attraction component described in Embodiment 1, so it has the beneficial effects of Embodiment 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com