Canal valve for modern agricultural production

A technology for water channels and valves, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of pollution and waste, poor lubricating effect of lubricating oil, etc., and achieve the effect of ensuring purity, good lubricating effect, and improving lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

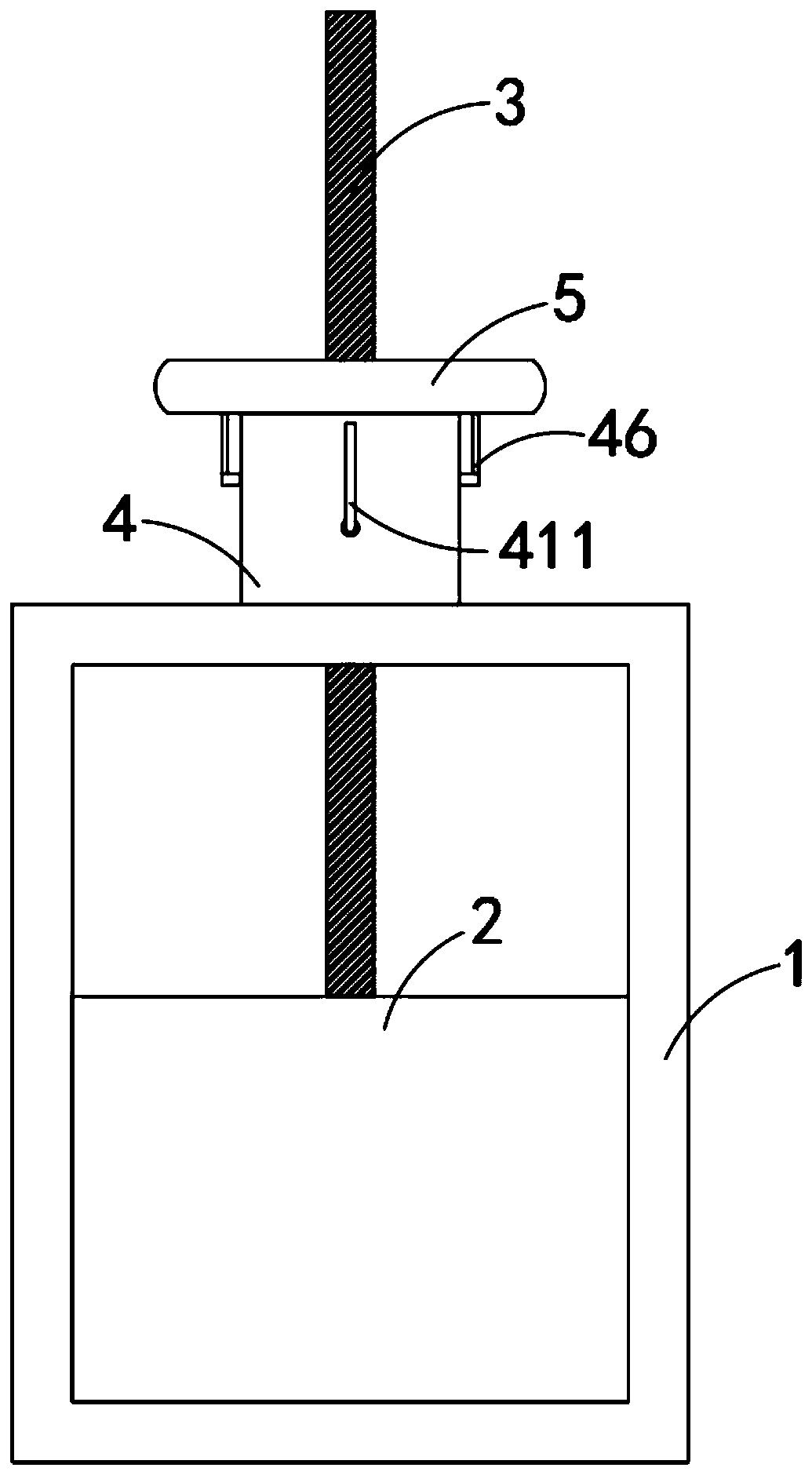

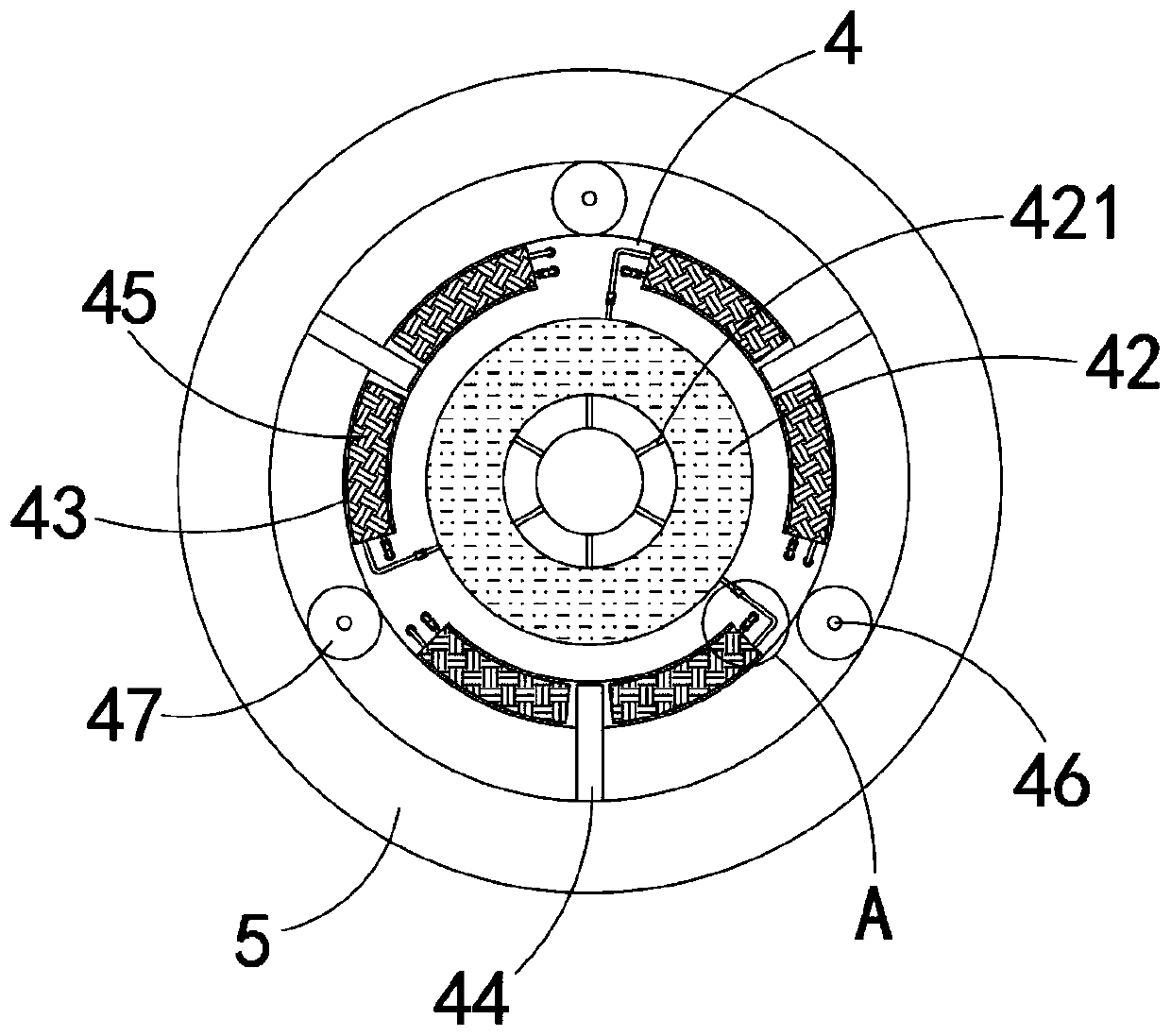

[0028] Such as Figure 1-4 As shown, a modern agricultural production canal valve includes a valve frame 1, a valve plate 2, a threaded rod 3, a rotating sleeve 4 and a rotating ring 5, the lower end of the rotating sleeve 4 is rotatably connected to the upper end of the valve frame 1, and the rotating The sleeve 4 is provided with a thread groove, the threaded rod 3 runs through the rotating sleeve 4 and is threadedly connected with the rotating sleeve 4, and the rotating sleeve 4 is provided with:

[0029] The liquid storage chamber 41, the side wall of the liquid storage chamber 41 is fixedly connected with an oil inlet pipe 411, and the oil inlet pipe 411 communicates with the lower bottom of the oil storage chamber 41;

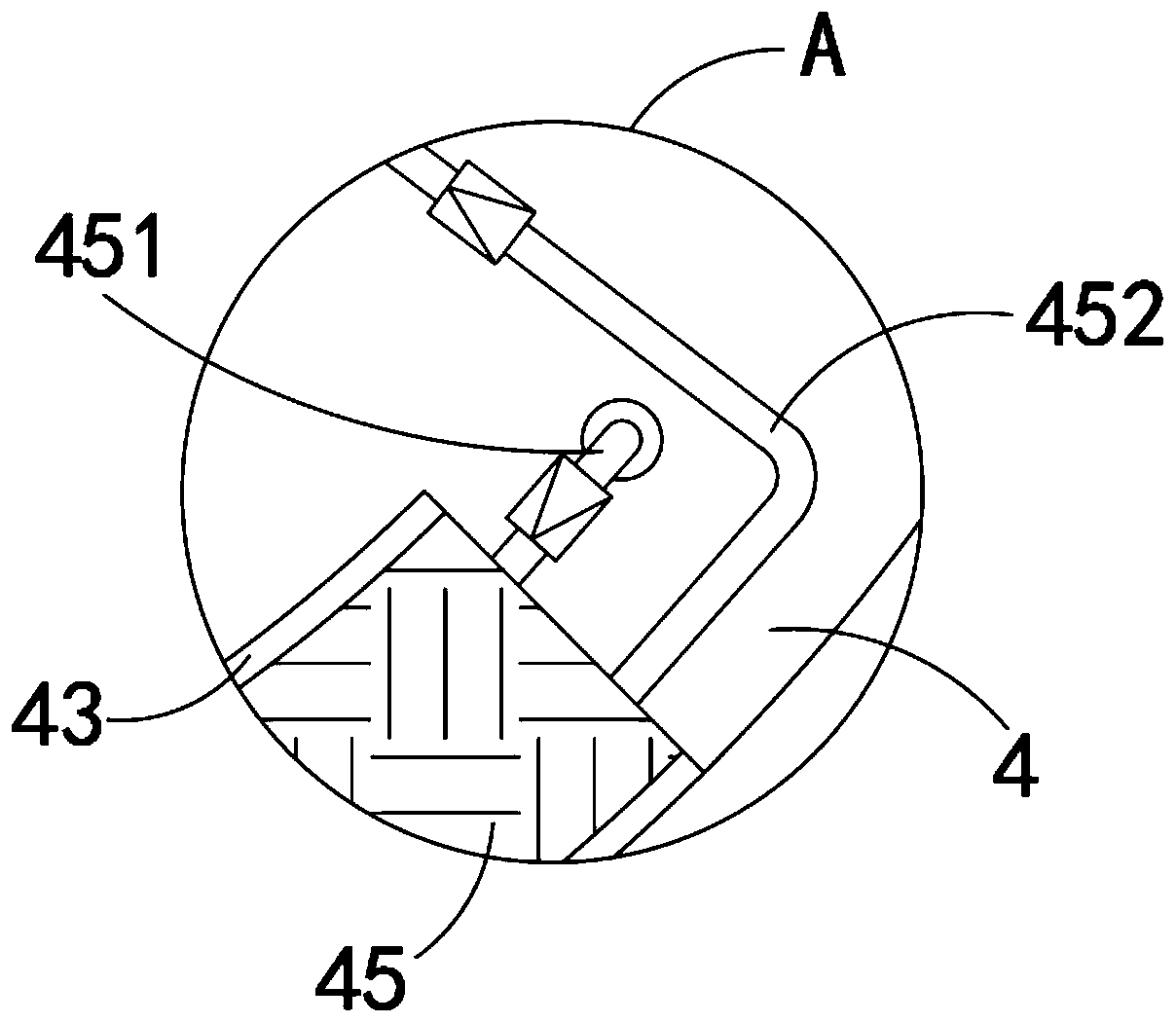

[0030] Two annular temporary storage chambers 42, two annular temporary storage chambers 42 are respectively arranged on the upper and lower sides of the liquid storage chamber 41, and the side walls of the annular temporary storage chambers 42 are provid...

Embodiment 2

[0036] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is: the input end of the oil inlet pipe 411 is bent to a horizontal state, and the input end of the oil inlet pipe 411 is rotatably connected with an L-shaped joint 412, and the oil inlet pipe 411 is made of transparent material , The pipe wall of the oil inlet pipe 411 is provided with a scale line, which can facilitate the observation of the remaining oil in the oil storage chamber 41 .

[0037] In this embodiment, by setting the L-shaped joint 412, the opening of the L-shaped joint 412 faces downward in the non-oiling state, so as to prevent dust or other sundries from entering the oil storage chamber 42, so as to ensure the purity of the lubricating oil. Improve the lubrication effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com