Pipeline type gasification device

A gasification device, pipeline technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of short reaction stroke, large space occupation, unreacted space utilization, etc., to extend the reaction stroke , convenient for precise control and the effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

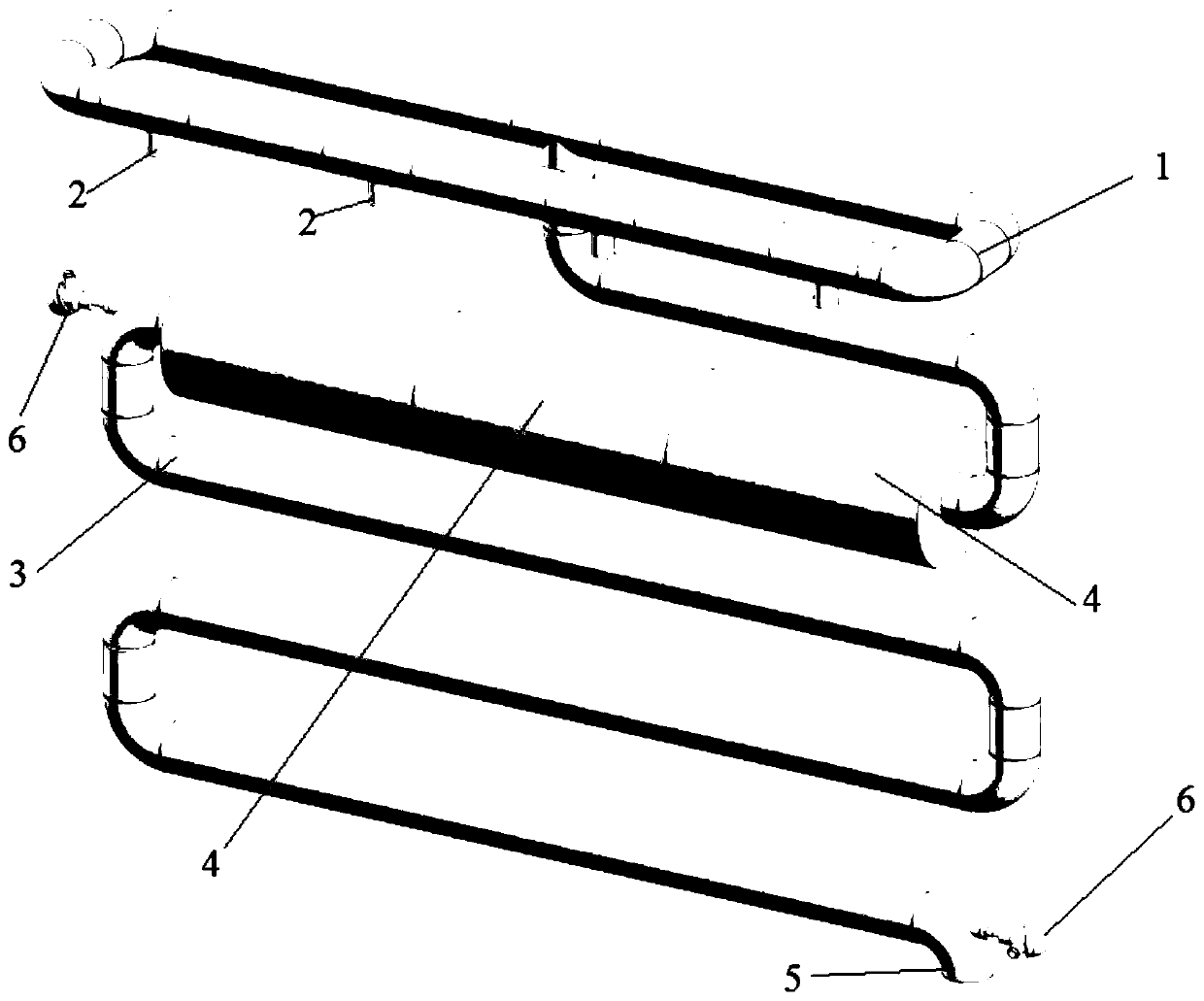

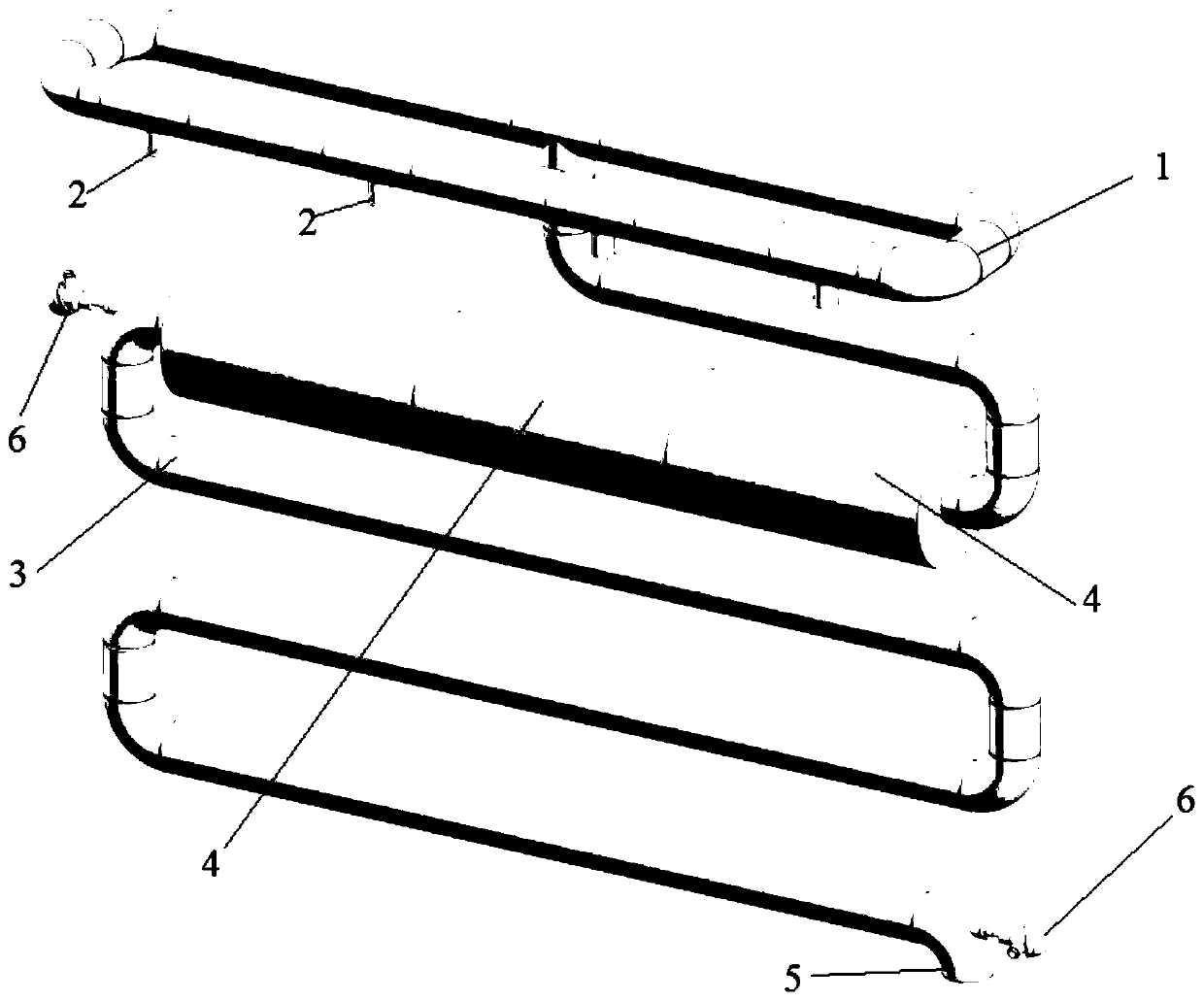

[0058] figure 1 A schematic structural diagram of a pipeline gasification device according to an embodiment of the present invention is shown.

[0059] The pipeline gasification device of this embodiment is used in the production process of coal-to-methane gas. In this process, after the primary preparation of methane gas, the generated methane gas and insufficiently reacted mixed gas are sent to the gasification system of the present invention. Pipeline gasification device, further gasification reaction, increase methane yield.

[0060] Such as figure 1 As shown, the pipeline gasification device includes:

[0061] An annular pipeline 1, on which a plurality of inlets 2 are equidistantly arranged;

[0062] A reaction pipeline 3, the reaction pipeline 3 is communicated with the annular pipeline 1, and the other end of the reaction pipeline 3 is provided with an air outlet 5;

[0063] Multiple sets of heating jackets 4, the heating jackets 4 are set on the reaction pipeline ...

Embodiment 2

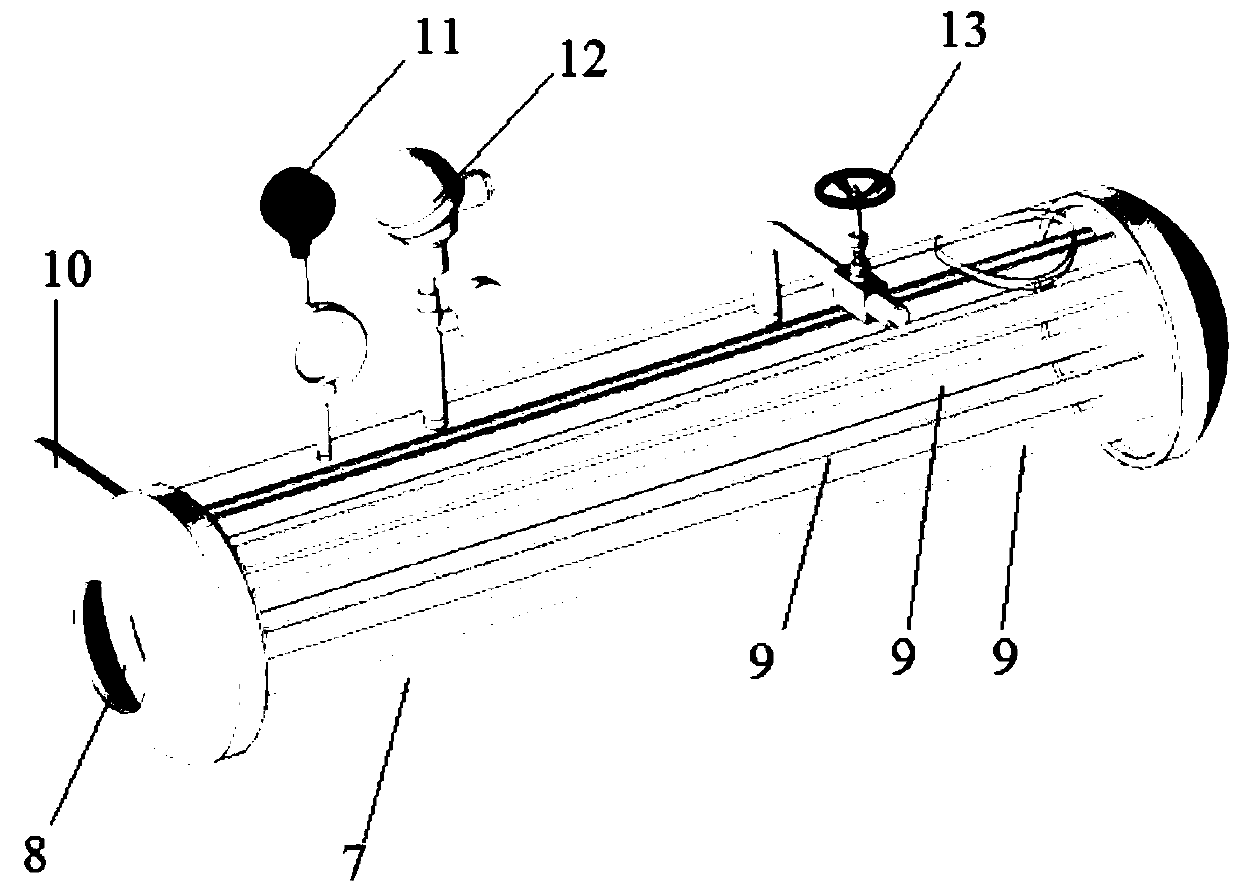

[0069] figure 1 A schematic structural diagram of a pipeline gasification device according to an embodiment of the present invention is shown. figure 2 A schematic structural diagram of a cooling tank according to an embodiment of the present invention is shown.

[0070] Such as Figure 1-Figure 2 As shown, the pipeline gasification device includes:

[0071] An annular pipeline 1, a plurality of inlets 2 are arranged at equal intervals on the annular pipeline 1;

[0072] A reaction pipeline 3, the reaction pipeline 3 is connected to the annular pipeline 1, and the other end of the reaction pipeline 3 is provided with an air outlet 5;

[0073] Multiple sets of heating jackets 4, 4 sets of heating jackets are set on the reaction pipeline 3;

[0074] The temperature sensor 6 and the pressure sensor, the temperature sensor 6 and the pressure sensor are arranged on the reaction pipeline 3;

[0075] The controller controls the heating jacket 4 to work according to the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com