Three-dimensional group cooperative coal caving simulation device for fully mechanized caving face and experimental method

A fully-mechanized caving face and simulation device technology, applied in the field of three-dimensional group collaborative coal caving simulation devices in fully mechanized caving face, can solve problems such as low coal caving efficiency, limited area of coal caving outlet, and low top-coal recovery rate. To avoid boundary effects, improve coal discharge efficiency, and optimize coal discharge process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

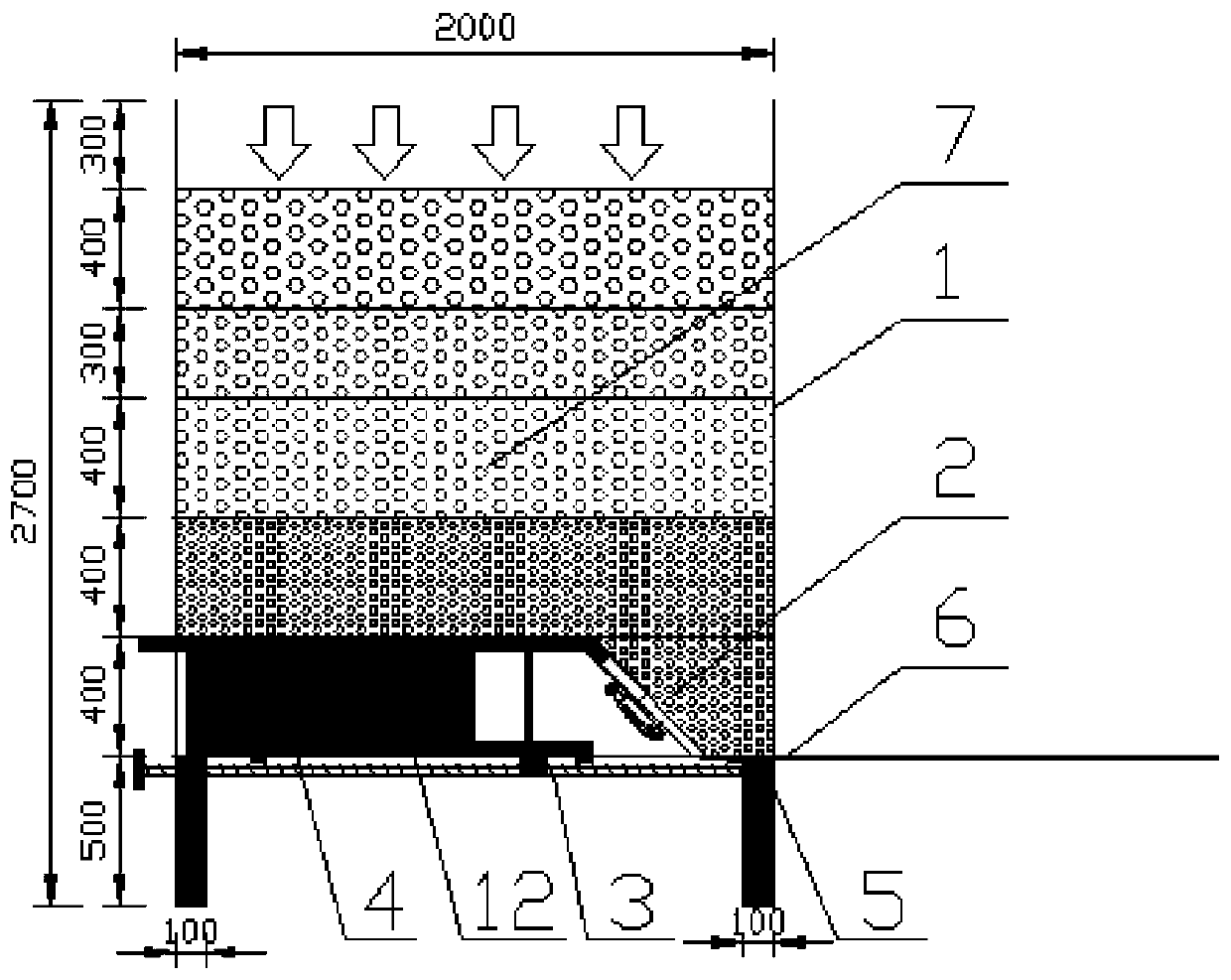

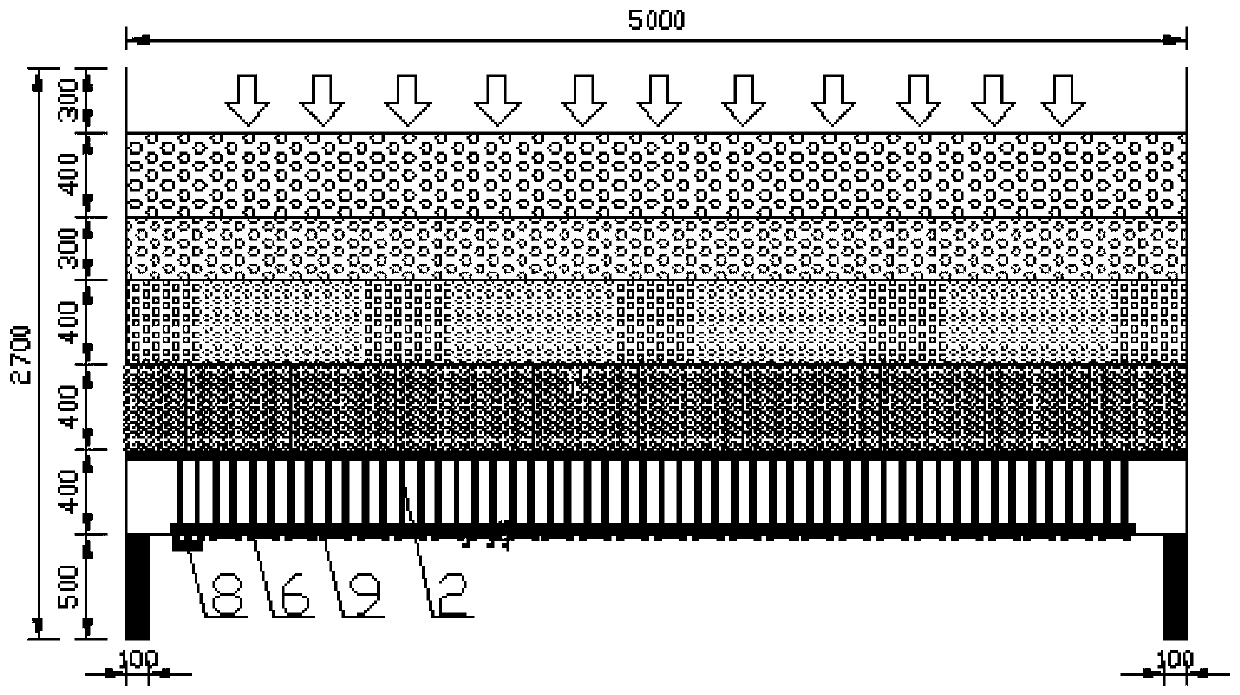

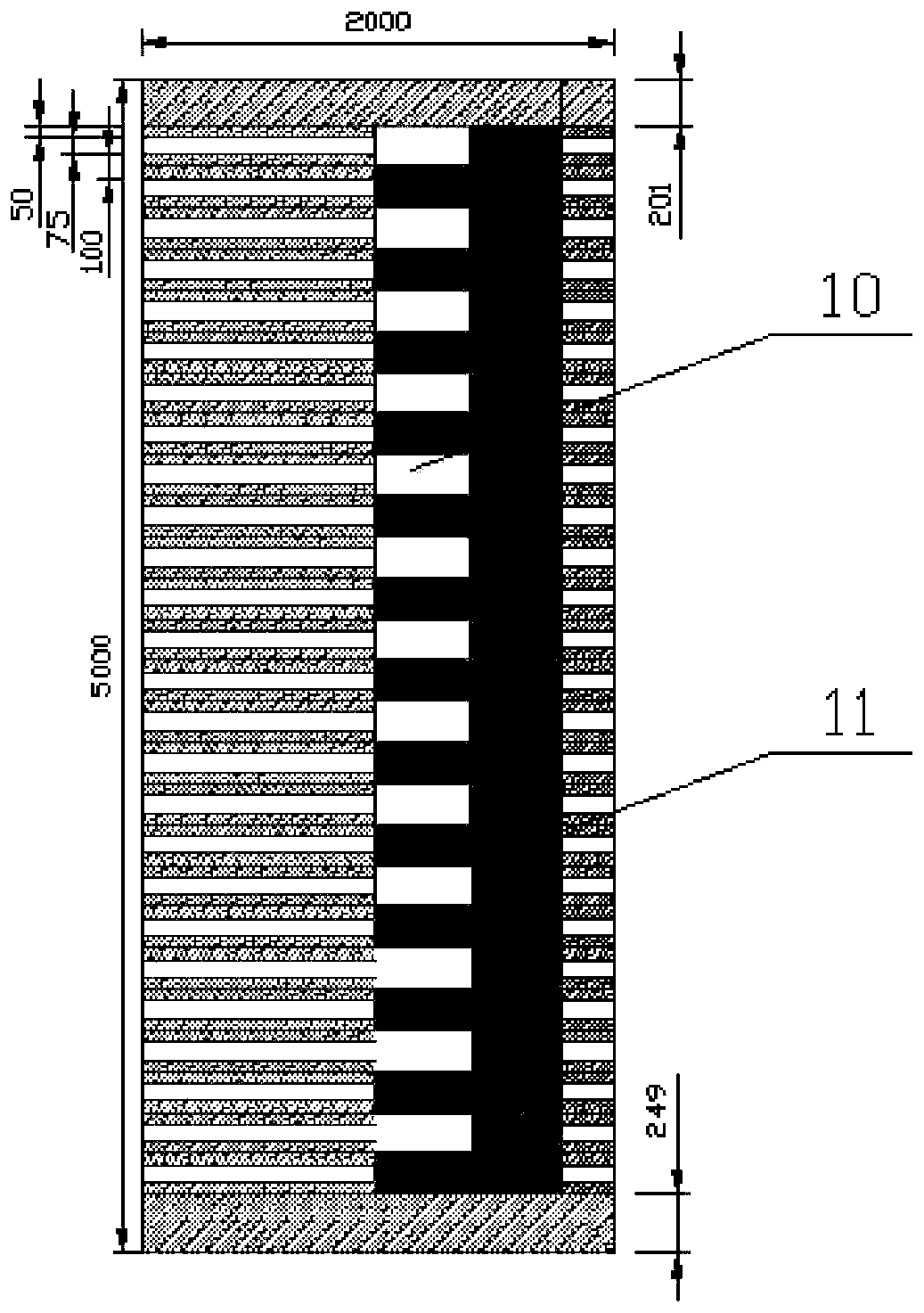

[0066] see Figure 1-7 , in an embodiment of the present invention, a three-dimensional group cooperative coal caving simulation device for a fully mechanized caving face, which includes an experimental device frame 1, a hydraulic support 2, a screw rod 3, a foam support body 4, a closed insert plate 6, and a simulated top coal The bulk material of gangue 7, the nut structure at the bottom of the hydraulic support 8, the closed plate carrier structure 9, the coal discharge step distance partition 12, the hydraulic oil pump 15, and the controller 16; it is characterized in that the hydraulic support 2 is set in the experimental device on the bottom plate of frame 1,

[0067] One side of the bottom plate of the experimental device frame 1 is also provided with a foam support body 4, and the foam support body 4 is supported with the coal step spacing partition 12;

[0068] The closed board carrier structure 9 is welded on the bottom plate of the experimental device frame 1; and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com