Artificial crevice device for simulating crevice corrosion research in deep-sea environment

A technology for crevice corrosion and deep-sea environment, which is applied in the direction of measuring devices, preparation of test samples, weather resistance/light resistance/corrosion resistance, etc. It can solve the problems of complex devices, single gap shape, and inability to change the opening angle, etc., so as to achieve convenient operation , Simple structure, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

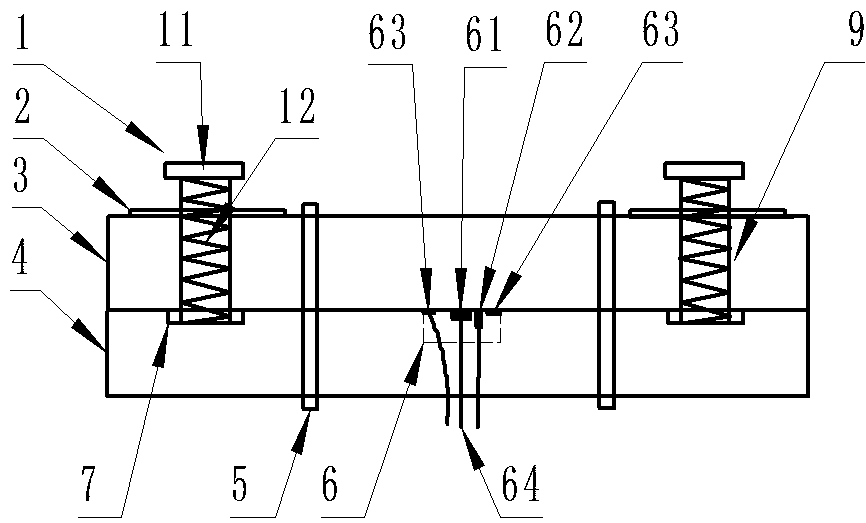

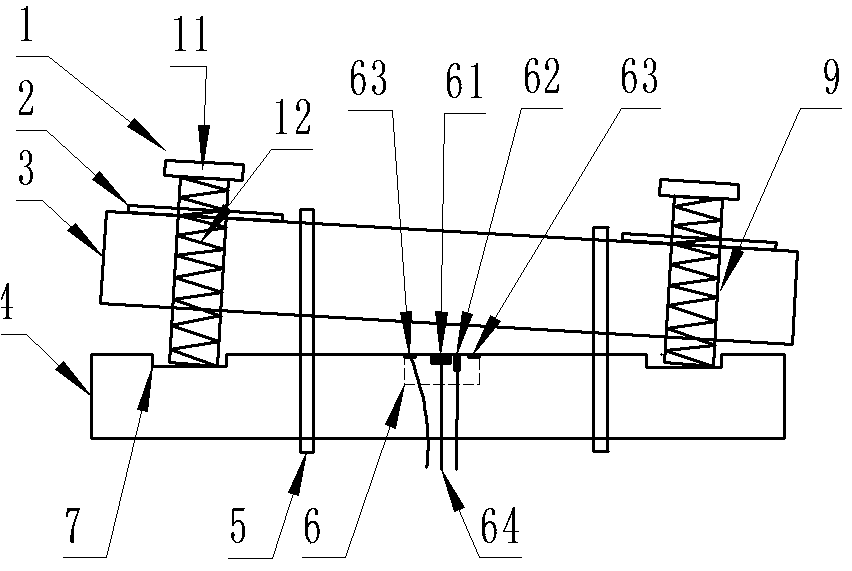

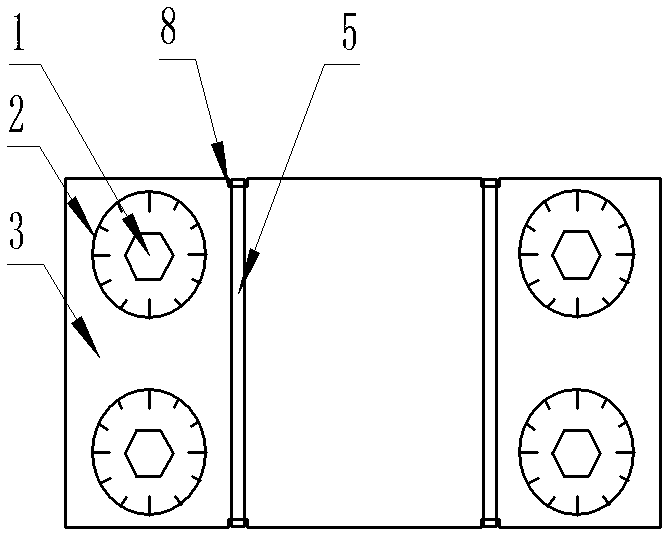

[0025] Attached below Figure 1-4 , an artificial crevice device of the present invention for simulating crevice corrosion research in a deep-sea environment will be described in detail below.

[0026] combined with figure 1, an artificial crevice device of the present invention for simulating crevice corrosion research in a deep sea environment, the device is mainly composed of a bolt 1, an angle disc 2, an upper splint 3, a lower splint 4, an elastic tightening device 5 and a solid three-electrode system 6 composition. The bolt 1 is made of hard ceramics, and the upper splint 3 and the lower splint 4 are made of hard epoxy resin. There are four threaded through holes 9 that match the bolts 1 around the upper splint 3, and two sets of elastic tightening devices 5 (such as strong rubber bands) are tightly attached to the lower splint 4 by surrounding sleeves; The hole 9 is screwed in toward the lower splint 4, so that the upper splint 3 moves in reverse relative to the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com