Dissolving cup cover opening mechanism of automatic release rate sampling system

A sampling system and automatic release technology, applied in the direction of material inspection products, testing pharmaceutical preparations, etc., can solve the problems of cumbersome operation of the test process, affect the continuity of the test process, reduce test efficiency, etc., achieve low production costs and maintain economical performance , the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

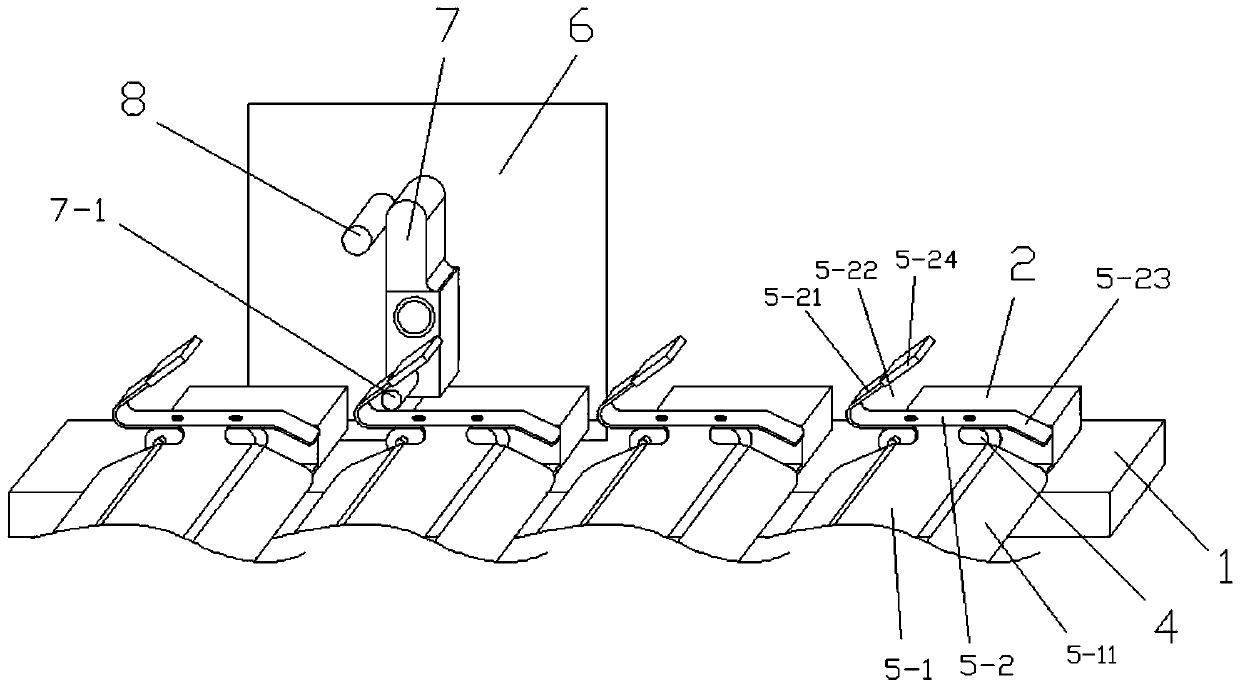

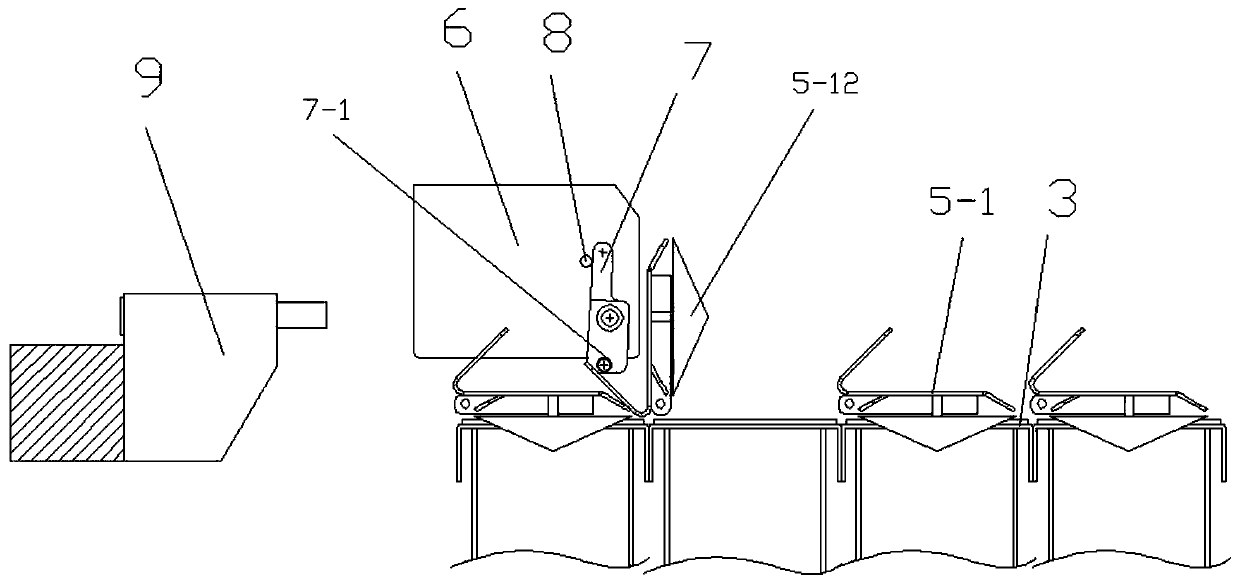

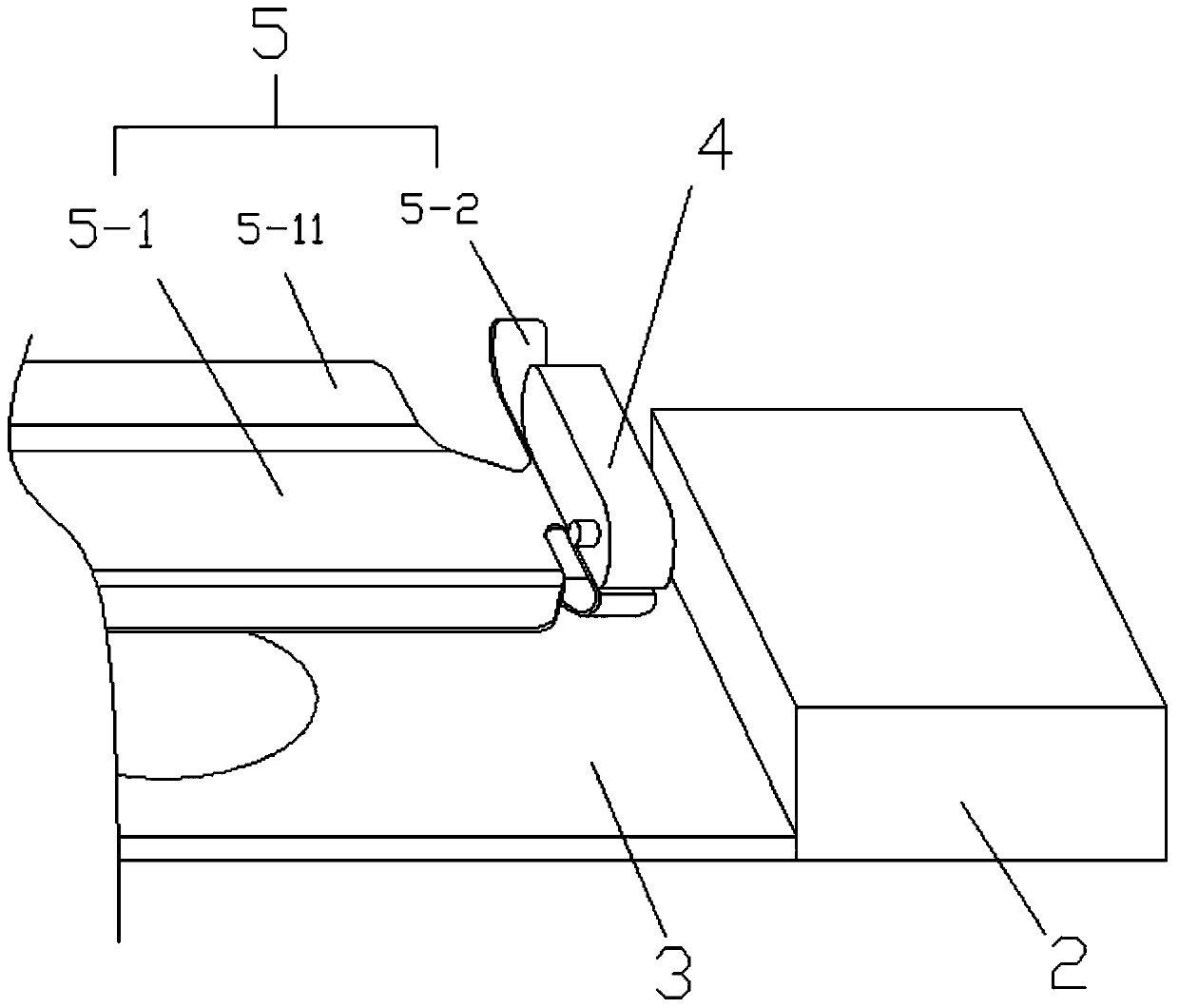

[0027] It can be seen from the accompanying drawings that a dissolving cup opening mechanism for an automatic release rate sampling system includes a horizontal plate, a dissolving cup holder fixing block, a dissolving cup holder, a rotating block, a dissolving cup cover, a dial fixing plate, a dial block, and a limiter. Rod, rebounder, the fixed block of the dissolving cup holder is arranged on the upper surface of the horizontal plate, and is fixedly connected with the horizontal plate by fasteners; the dissolving cup holder has a rectangular thin plate structure, and the dissolving cup The frame is vertically fixedly connected to the bottom end of one side of the cup-dissolving frame fixed block; the rotating block is arranged on one side of the cup-dissolving frame fixed block, and one end of the rotating block is rotationally connected with the cup-dissolving frame fixed block through a shaft The melting cup cover is arranged above the melting cup holder, the melting cup c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap