Square ceramic tube shell and preparation process

A ceramic tube shell and preparation process technology, which is used in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the failure of tube-shell welding, failure of temperature shock resistance, and uneven welding stress distribution of square ceramic tube-shell And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

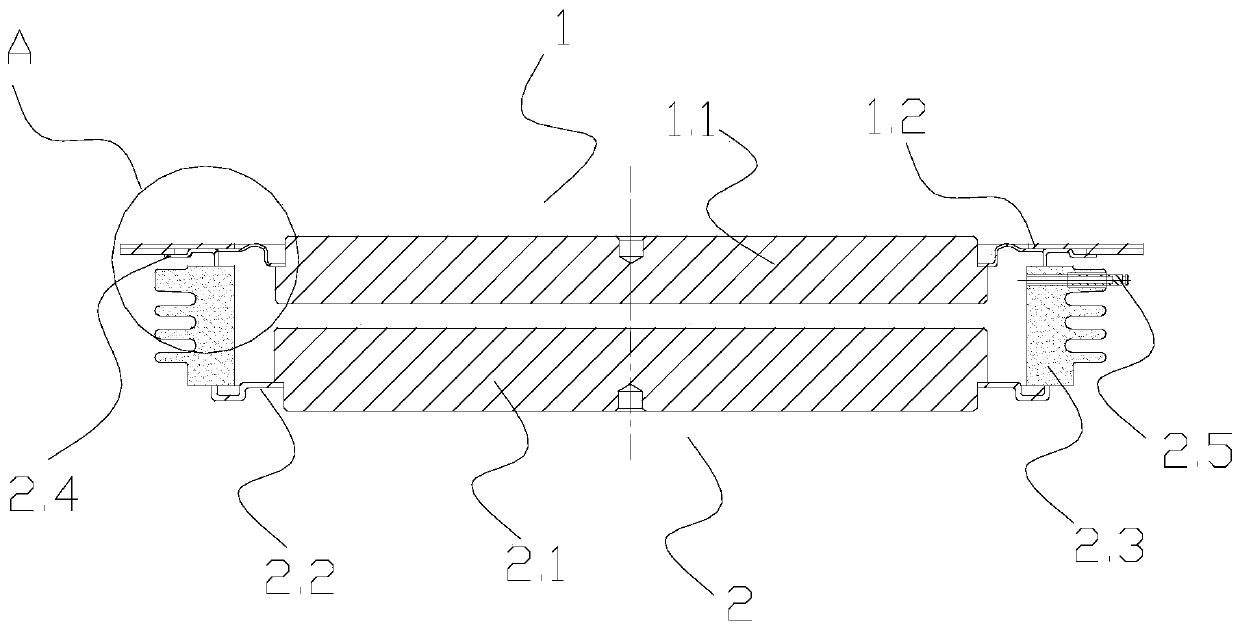

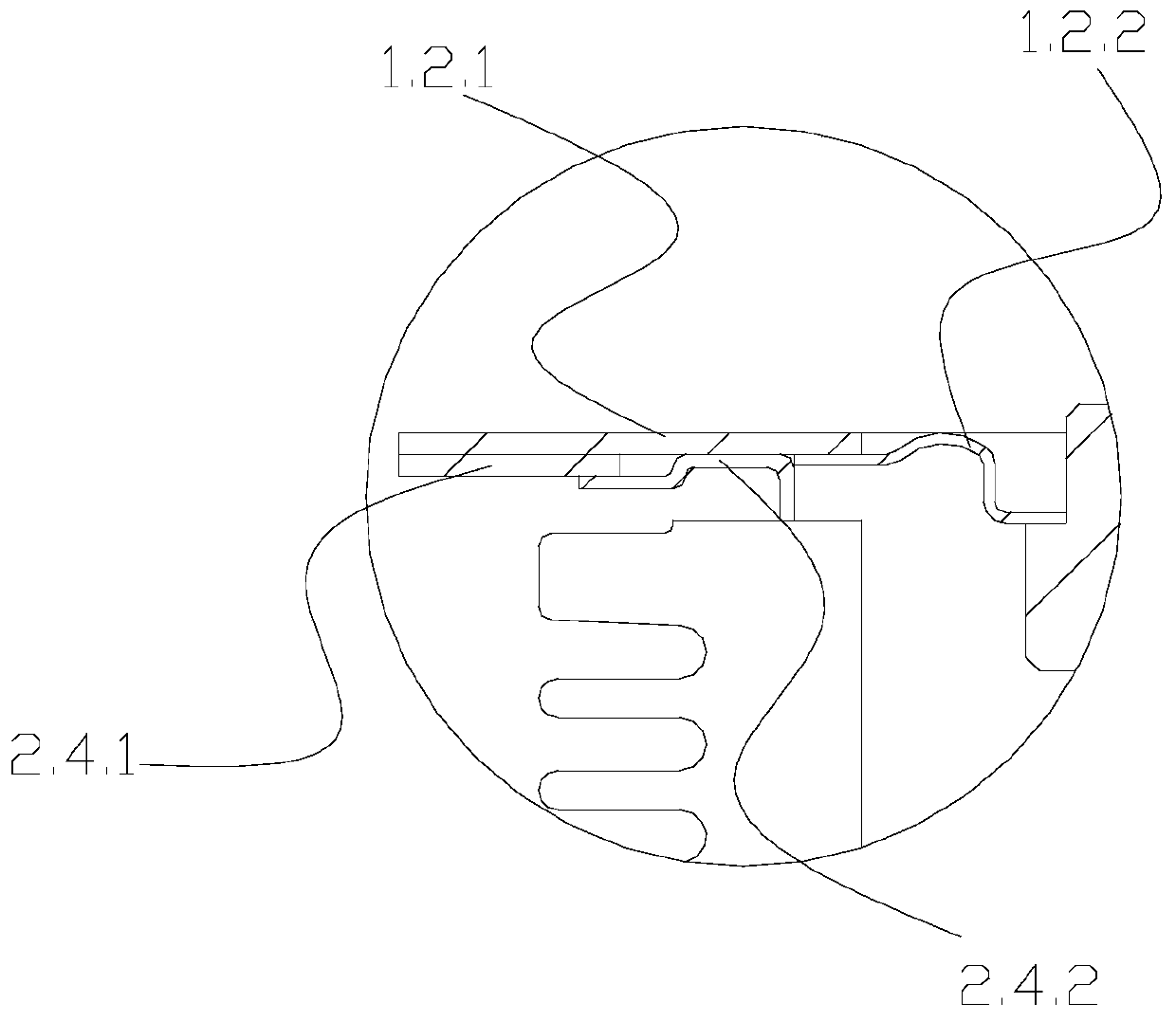

[0022] Such as figure 1 , as shown in 2, a square ceramic shell in the present embodiment includes a loam cake 1 and a ceramic base 2, the loam cake 1 is placed on the ceramic base 2, and the loam cake 1 includes a cathode square electrode 1.1 and cathode split flange 1.2, the cathode split flange 1.2 is concentrically welded on the outer edge of the cathode square electrode 1.1, and the cathode split flange 1.2 includes a cathode thick ring 1.2.1 and a cathode thin ring 1.2.2 The inner edge of the cathode thick ring 1.2.1 is concentrically welded to the outer edge of the cathode thin ring 1.2.2, and the inner edge of the cathode thin ring 1.2.2 is concentrically welded to the outer edge of the cathode square electrode 1.1.

[0023] The ceramic base 2 includes an anode square electrode 2.1, an anode sealing ring 2.2, a square ceramic ring 2.3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap