Control Mechanism and Method for Smooth Switching of Combine Harvester's Forward Speed

A combine harvester, advance speed technology, applied to harvesters, agricultural machinery and implements, cutters, etc., can solve problems that are not conducive to harvesting operations of harvesters, hydraulic system impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

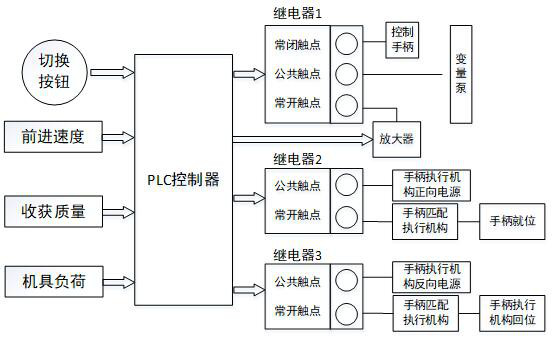

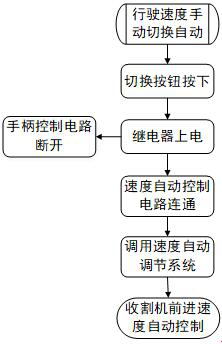

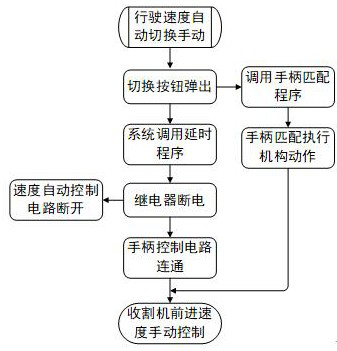

[0020] Such as figure 1 As shown, the control mechanism for the smooth switching of the forward speed of the combine harvester includes a switch button, a control handle, a first relay, a second relay, a third relay, a PLC controller, an amplifier, and a handle matching actuator, which are used to obtain the forward speed, The PLC controllers for harvesting quality and implement load are respectively connected to the switching button, the first relay, the second relay, the third relay and the amplifier, and each relay is respectively provided with a common contact, a normally open contact and a normally closed contact; One relay is respectively connected with the control handle, the variable pump, and the amplifier; the second relay is respectively connected with the forward power supply of the handle actuator and the handle matching actuator used to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com