A car wash brush

A car washing and brush technology, applied in brushes, brushes, applications, etc., can solve the problems of car body surface paint damage, incomplete equipment functions, and high waste water treatment costs, achieving low production costs, complete functions, and low costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

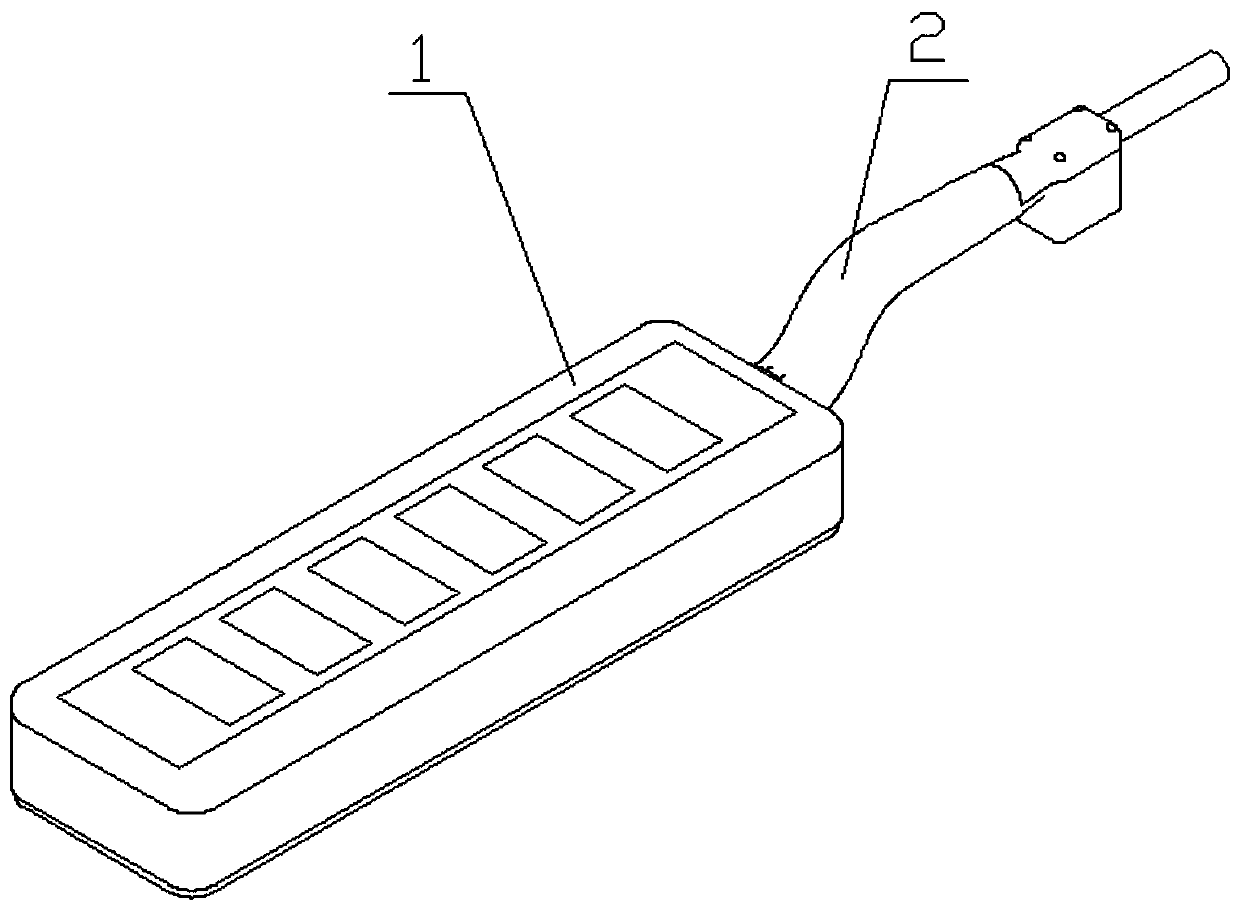

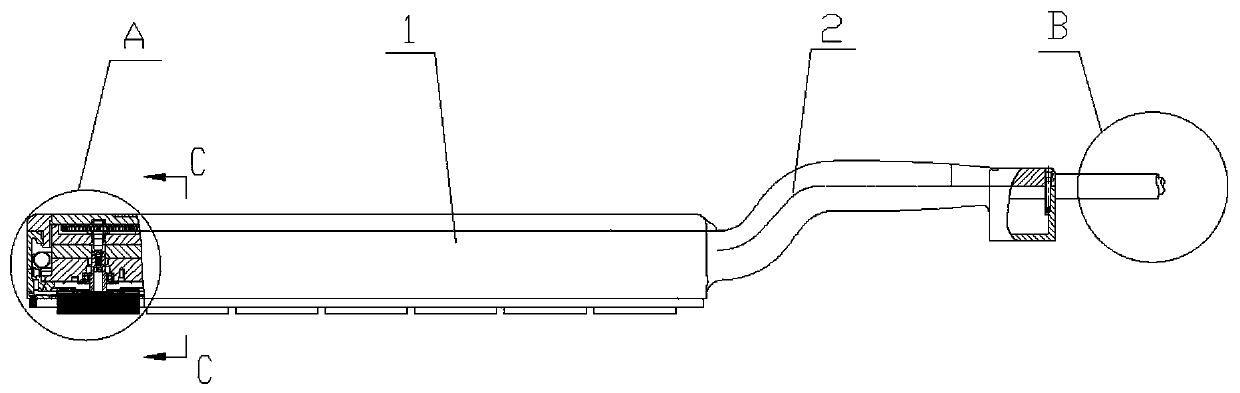

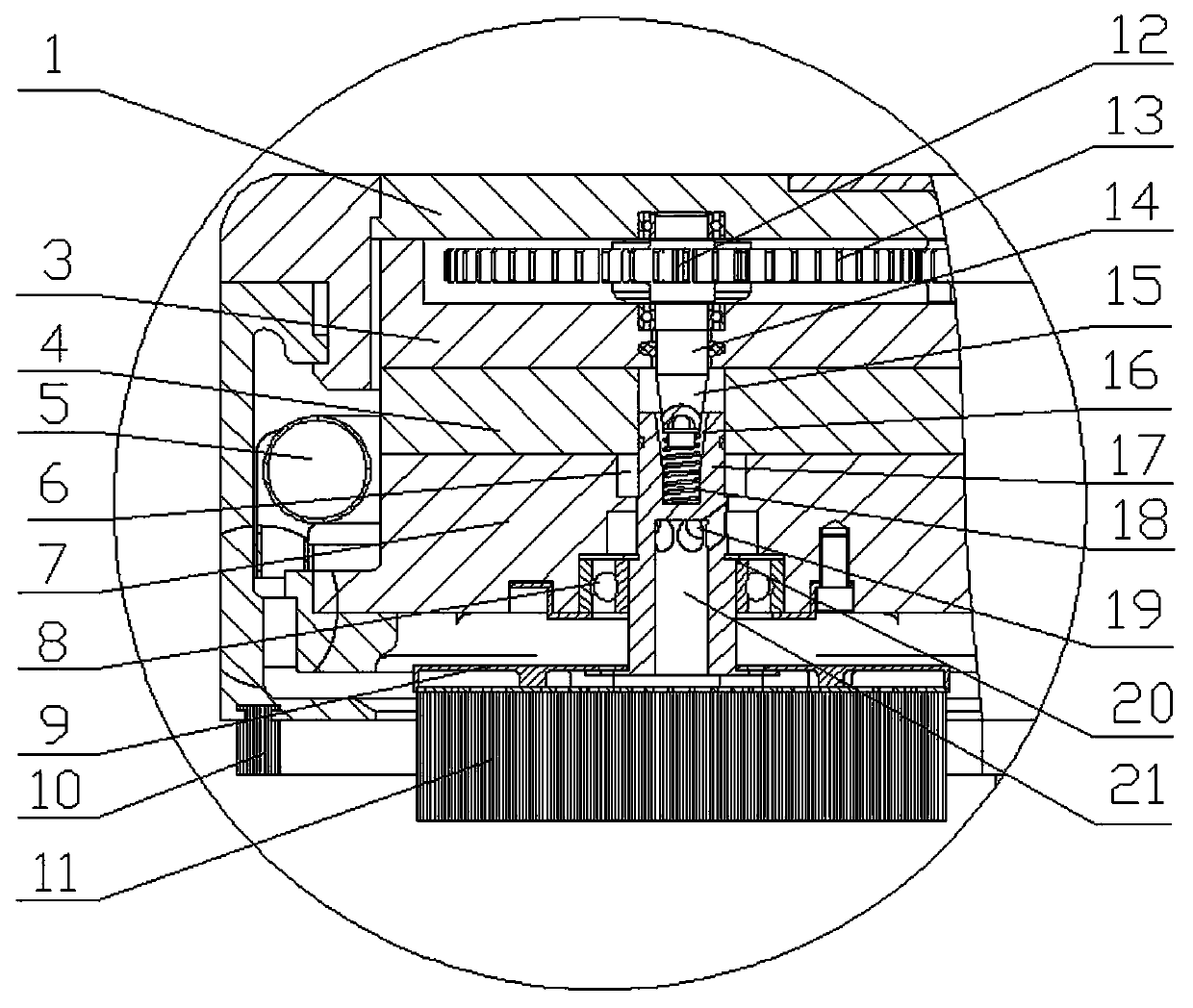

[0029] Such as figure 1 As shown, a brush for car washing of the present invention includes a rectangular box-shaped brush body 1 and a brush handle 2 arranged at one end of the brush body 1 to facilitate holding. The brush body 1 has a cavity with an open bottom. The cavity of the brush body 1 is provided with a plurality of rotatable brush core mechanisms, a turbine drive mechanism that drives the plurality of brush core mechanisms to rotate through a gear transmission mechanism, and a turbine drive mechanism for adsorbing sewage The adsorption mechanism. The worm gear drive mechanism is connected to the high-pressure water pump, which is used to evenly distribute the high-pressure water to the brush heads everywhere, and convert the high-pressure energy of the water into the rotating mechanical energy required by the brush head, so that the rotating brush head cooperates with the high-pressure water. car wash. The adsorption mechanism is connected with the water pump to suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com