Oil-gas separation device which is arranged outside automobile fuel tank

A separation device and fuel tank technology, applied in the direction of power devices, separation methods, liquid degassing, etc., can solve the problems of high cost and inconvenient installation, and achieve reduced production and processing costs, convenient overall operation, and ingenious overall design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

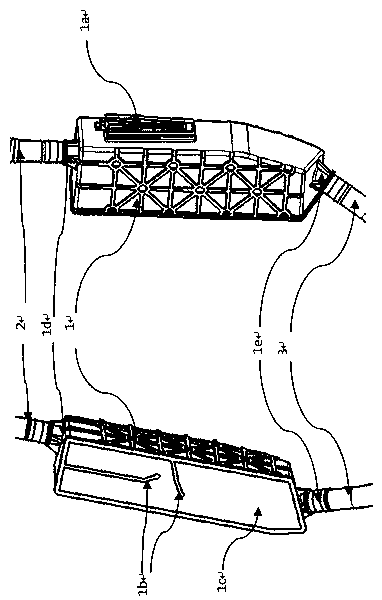

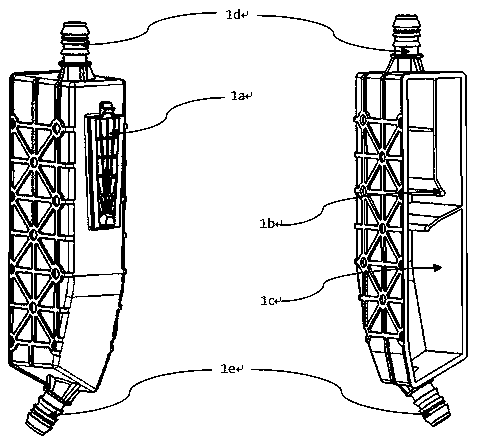

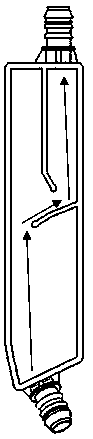

[0021] Embodiment 1: see Figure 1-Figure 7 , an oil-air separation device with an external fuel tank of an automobile, the oil-air separation device includes a main body 1 and an upper connecting pipeline 2 and a lower connecting pipeline 3 arranged at both ends of the main body 1, and the main body 1 includes a buckle fixing structure 1a, grid structure 1b, sealing cover plate 1c, and oil and gas inlet and outlet channels 1d and 1e, the buckle structure 1a, internal grille 1b, oil and gas inlet and outlet channels are integrally injection molded with the body 1, and the sealing cover plate 1c is welded and fixed In body 1. The overall shape of the cover coincides with the welding surface of the oil-gas separation body. There are a number of limit protrusions on the inside of the cover to facilitate the welding and positioning of the cover and the body, and the protrusions and the cover are integrally formed by injection molding. The oil-air separation device is set outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com