Ore screening device with damping and noise reduction functions

A screening device and functional technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of high labor cost, low crushing efficiency, inconvenient operation, etc., and achieve the effect of good vibration effect, improved efficiency, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

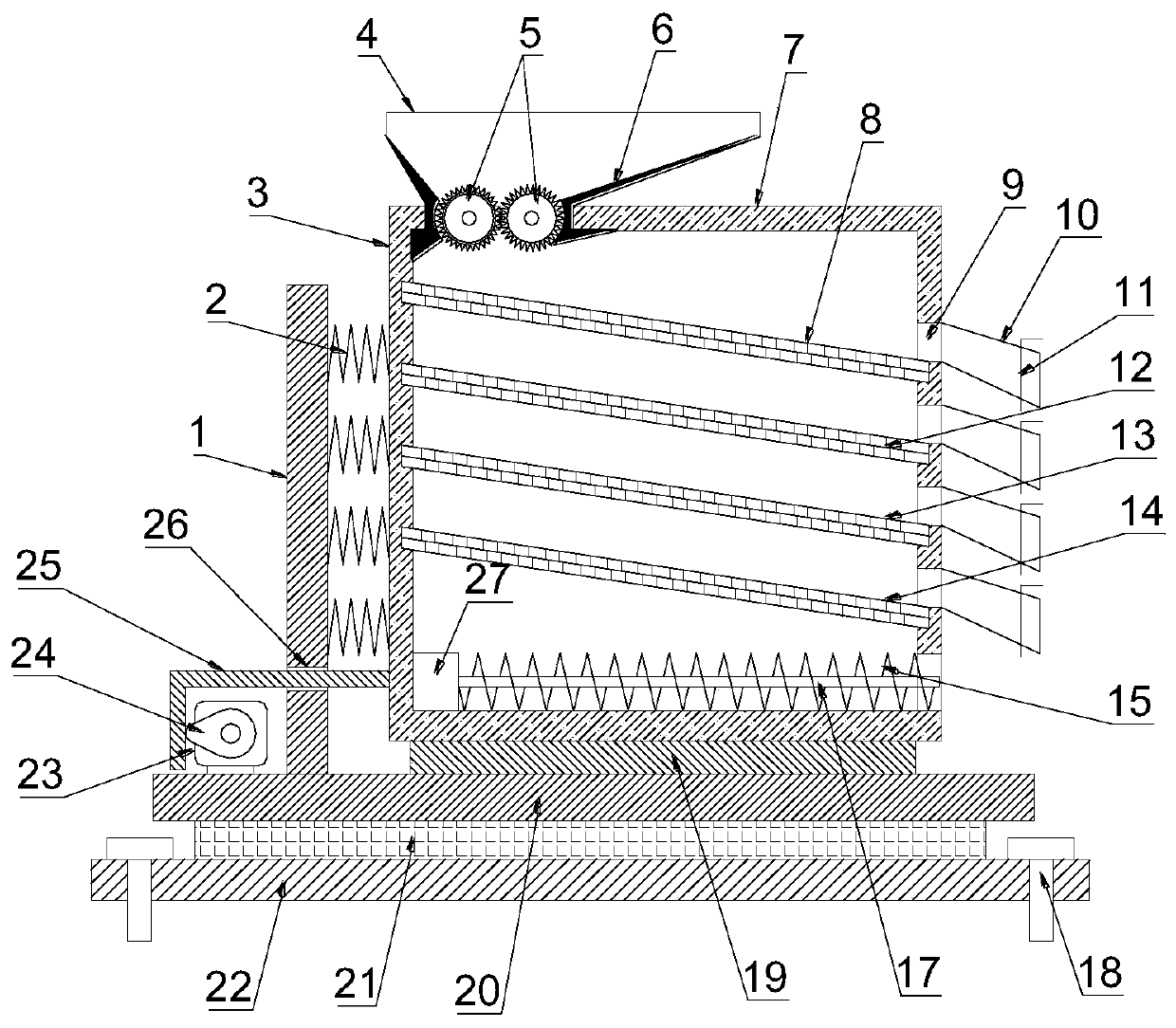

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

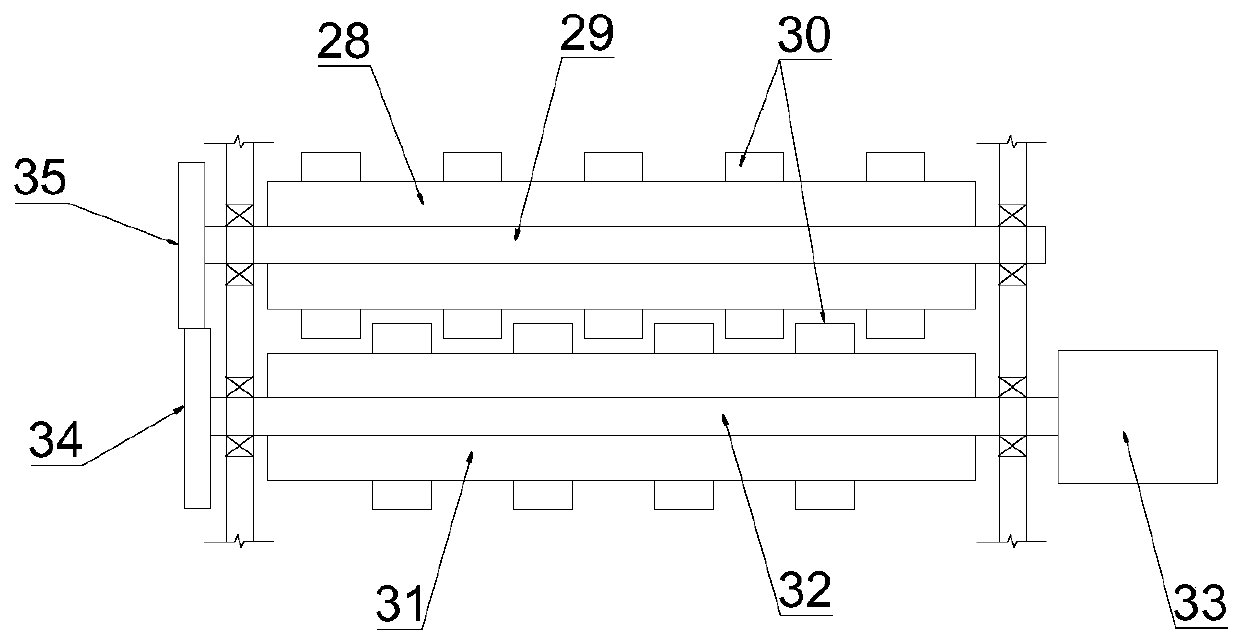

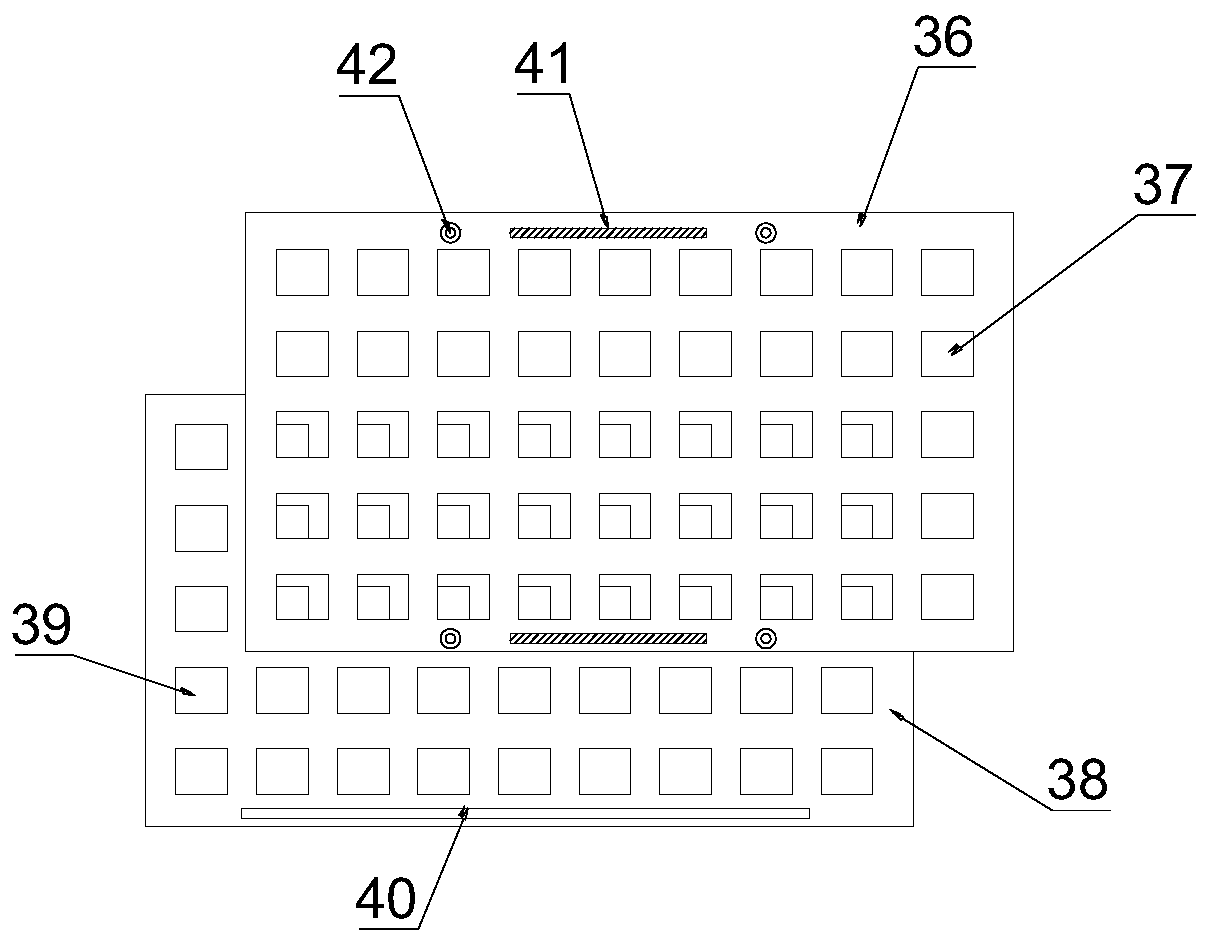

[0023] see Figure 1-4 , an ore screening device with shock and noise reduction functions, comprising a vertical plate 1, a screening box 3, a crushing roller group 5, a first screen 8, a second screen 12, a third screen 13, a fourth screen Net 14, horizontal plate 20 and L-shaped connecting rod 25, the top of the screening box 3 is connected with a box cover 7, the box cover 7 and the screening box 3 are connected by bolts, the top of the box cover 7 is connected to the feeding hopper 4, and the top of the box cover 7 is connected to the feeding hopper 4. The inner wall of the hopper 4 is provided with a wear-resistant layer 6, and the bottom of the hopper 4 is equipped with a crushing roller group 5, which includes a crushing roller 28, a roller shaft 29, crushing teeth 30, a crushing roller 2 31, and a roller shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com