A kind of additive manufacturing method of cast iron roll

A cast iron roll and additive manufacturing technology, which is applied in the field of metal surface treatment, can solve problems such as the inability to complete the additive manufacturing of cast iron rolls and cracks on the surface of cast iron rolls, and achieve the effects of increased service life, small heat input, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

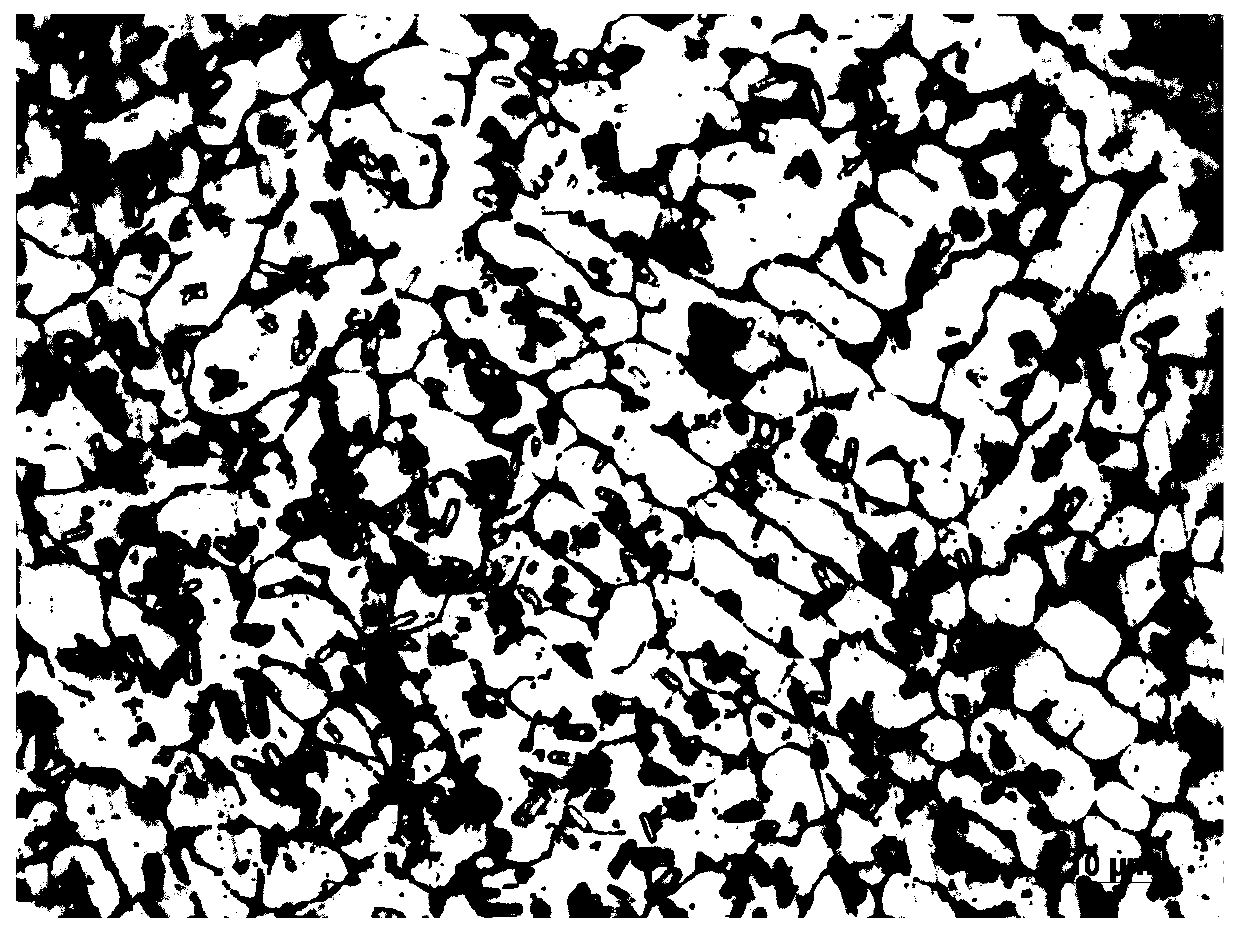

Image

Examples

Embodiment 1

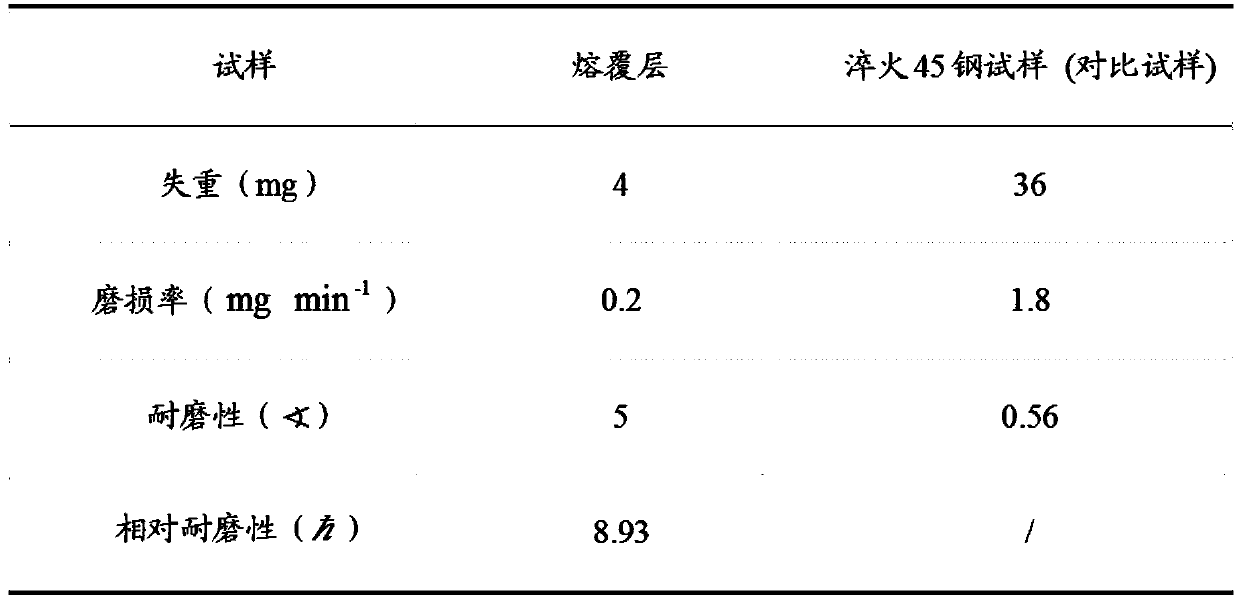

[0035] Turning to remove the wear fatigue layer on the surface of the scrapped cast iron roll, the amount of unilateral turning is 0.5mm; use absolute ethanol to clean the surface of the turned cast iron roll to remove impurities such as oil stains; conduct non-destructive testing on the cast iron roll, using magnetic particle inspection and ultrasonic flaw detection , check whether there are defects such as surface and internal cracks in the cast iron roll; after the inspection is qualified, the surface of the cast iron roll that has undergone the above pretreatment is welded by CMT technology (the welding wire adopts D506 welding wire, the diameter of the welding wire is 1.2mm, and the wire feeding speed is 4.5mm / min, welding speed is 24mm / min, torch angle is 0°, dry elongation is 12mm, gap is 1.2mm, shielding gas is 90% argon + 10% CO 2, the gas flow rate is 15L / min), through multi-layer welding, a surface weld layer is formed on the cast iron roll, so that the thickness of...

Embodiment 2

[0042] The wear and fatigue layer on the surface of the scrapped cast iron roll is removed by turning, and the amount of unilateral turning is 1mm; the surface of the cast iron roll after turning is cleaned with absolute ethanol to remove impurities such as oil stains; non-destructive testing is carried out on the cast iron roll, using magnetic particle inspection and ultrasonic flaw detection, Check whether there are defects such as surface and internal cracks in the cast iron roll; after the inspection is qualified, the surface of the cast iron roll that has undergone the above pretreatment is welded by CMT technology (the welding wire adopts D506 welding wire, the diameter of the welding wire is 1.2mm, and the wire feeding speed is 4.5mm / min. The welding speed is 30mm / min, the torch angle is 0°, the dry elongation is 15mm, the gap is 1.2mm, and the shielding gas is 90% argon + 10% CO 2 , the gas flow rate is 15L / min), through multi-layer welding, a surface welding layer is f...

Embodiment 3

[0044] Turning to remove the wear fatigue layer on the surface of the scrapped cast iron roll, the amount of unilateral turning is 0.5mm; use absolute ethanol to clean the surface of the turned cast iron roll to remove impurities such as oil stains; conduct non-destructive testing on the cast iron roll, using magnetic particle inspection and ultrasonic flaw detection , check whether there are defects such as surface and internal cracks in the cast iron roll; after the inspection is qualified, the surface of the cast iron roll that has undergone the above pretreatment is welded by CMT technology (the welding wire adopts D506 welding wire, the diameter of the welding wire is 1.2mm, and the wire feeding speed is 4.5mm / min , the welding speed is 26mm / min, the torch angle is 0°, the dry elongation is 13mm, the gap is 1.2mm, and the shielding gas is 90% argon + 10% CO 2 , the gas flow rate is 15L / min), through multi-layer welding, a surface welding layer is formed on the cast iron ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com