Novel underwater submerged arc welding device and welding method

A submerged arc welding, a new technology, applied in the direction of welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of obvious quenching effect of weld seam, reduce the mechanical properties of welded joints, etc., and achieve suitable for large-scale promotion and application, low cost, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

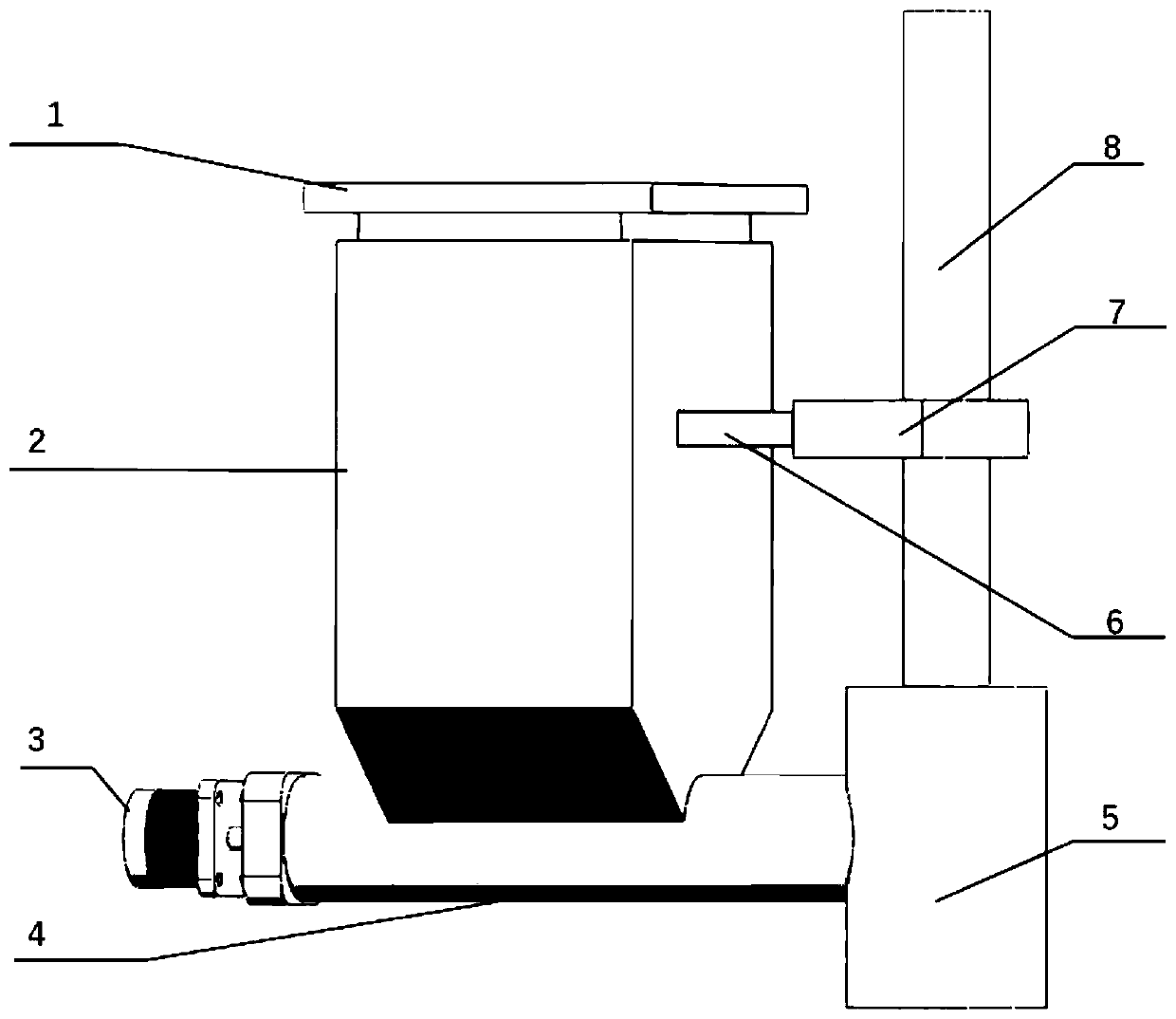

[0029] A new type of underwater submerged arc welding device, including a solder box and a sleeve. Solder is provided in the solder box. A solder delivery pipe is provided at the bottom of the solder box. One end of the solder delivery pipe is connected to the sleeve, and the other end of the solder delivery pipe is provided with a step There is an auger inside the feeder motor and the solder conveying pipe, and the auger is connected with the stepping motor; the top of the sleeve is connected with the gun barrel of the welding torch, and the lower part of the welding torch is annularly nested inside the sleeve. By adjusting the rotation speed of the stepping motor, the control of the solder conveying speed can be realized, and the purpose of controlling the solder coverage thickness of the welding zone can be further achieved.

[0030] The solder is a viscous liquid water-resistant solder, and its components include HJ350 submerged arc flux and epoxy resin with a weight ratio ...

Embodiment 2

[0033] A new type of underwater submerged arc welding device, its structure is as described in Example 1, the difference is that in order to prevent the solder box from entering water, a cover is provided on the top of the solder box, and a rubber ring is provided between the cover and the solder box . The stepper motor is also waterproofed and sealed.

Embodiment 3

[0035] A new type of underwater submerged arc welding device, its structure is as described in Embodiment 1, the difference is that the gun barrel of the welding torch is fixedly connected with the solder box through the connecting plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com