Quasi-continuous laser drilling and cutting process for amorphous alloy

An amorphous alloy, laser drilling technology, applied in laser welding equipment, metal processing equipment, manufacturing tools and other directions, can solve problems affecting material properties, adverse effects, etc., to reduce the amount of slag, save resources, and improve cutting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

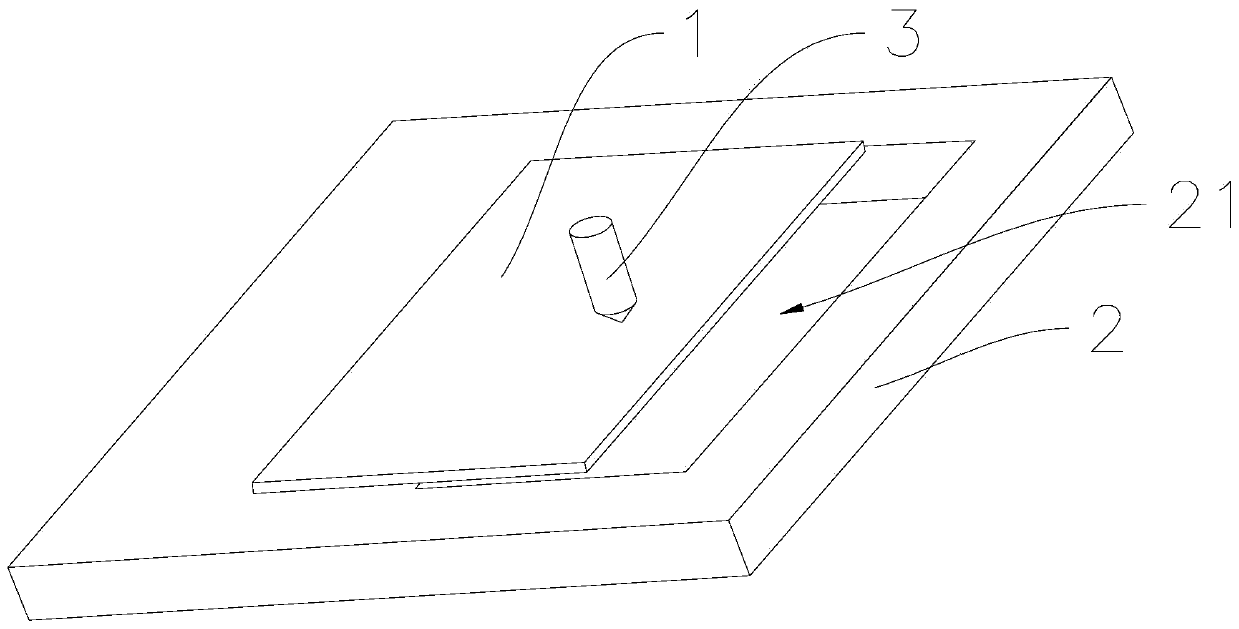

[0033] Example 1

[0034] The thickness of the amorphous alloy 1 to be cut is 0.6mm, the groove depth is 20mm, and the width is 10mm. The quasi-continuous laser frequency emitted by the quasi-continuous laser 3 is 450Hz, the power is 500W, the cutting speed is 40mm / s, and the cooling inert atmosphere is Nitrogen. The diameter of each hole formed in the punching and cutting process is 20 μm, and the distance between two adjacent holes is 5 μm.

[0035] Cutting result: There is no slag and burr in the cutting seam, and there is no slag splash on the finished amorphous alloy product.

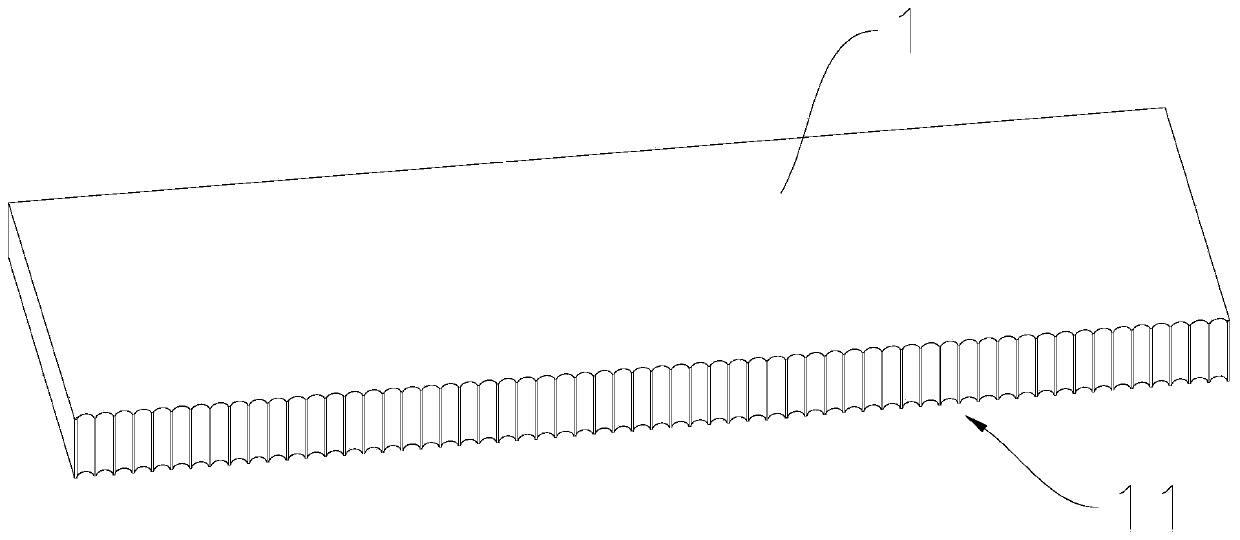

[0036] Such as image 3 with 4 As shown, the slit obtained by punching and cutting in Example 1 is wavy, which is a shape formed by punching and cutting. The slit is bright and non-oxidized, without dross and burrs.

[0037] Such as Figure 5 As shown, there is no slag splashing on the amorphous alloy product obtained by punching and cutting in Example 1.

Example Embodiment

[0043] Example 2

[0044] The thickness of the amorphous alloy 1 to be cut is 2mm, the groove depth is 20mm, and the width is 15mm. The quasi-continuous laser frequency emitted by the quasi-continuous laser 3 is 400Hz, the power is 1200W, the cutting speed is 35mm / s, and the cooling inert atmosphere is nitrogen. . The diameter of each hole formed in the punching and cutting process is 30 μm, and the distance between two adjacent holes is 3 μm.

[0045] Cutting result: There is no slag and burr in the cutting seam, and there is no slag splash on the finished amorphous alloy product.

Example Embodiment

[0046] Example 3

[0047] The thickness of the amorphous alloy 1 to be cut is 0.5mm, the groove depth is 10mm, and the width is 5mm. The frequency of the quasi-continuous laser 3 is 2000Hz, the power is 100W, the cutting speed is 50mm / s, and the cooling inert atmosphere is Nitrogen. The diameter of each hole formed in the punching and cutting process is 10 μm, and the distance between two adjacent holes is 10 μm.

[0048] Cutting result: There is no slag and burr in the cutting seam, and there is no slag splash on the finished amorphous alloy product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap