Whole-row transplantation device for glass slides

A technology of glass slides and equipment, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, troublesome replacement, labor and time consumption, etc., and achieve labor saving and good market application value , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

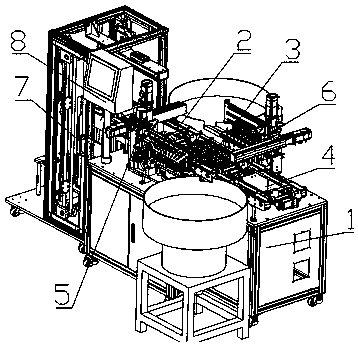

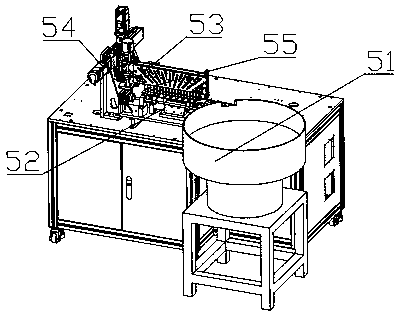

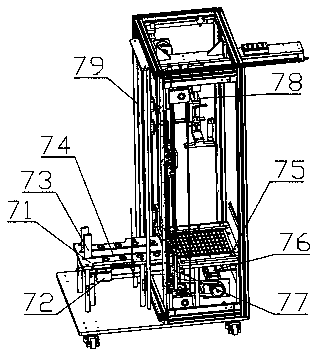

[0032] Such as figure 1 , figure 2 As shown, Embodiment 1 of the present invention: a slide transplanting equipment in a row, including a frame 1, a left arrangement mechanism 5, a right arrangement mechanism 6, a tray loading mechanism 7, a waiting station 2, The sheet arrangement station 3 and the discharge station 4, the waiting station 2, the sheet arrangement station 3, and the discharge station 4 are arranged on the frame side by side from the feed end to the discharge end of the frame 1 in sequence. 1, the tray loading mechanism 7 is located on the left side of the feed end of the frame 1 and adjacent to the waiting station 2, and the tray loading mechanism 7 will be used to place the load The empty tray of the glass slides is transported to the waiting station 2, and the left side arrangement mechanism 5 and the right side arrangement mechanism 6 are both arranged on the platform of the frame 1, and are respectively located at the arrangement station 3 The left and ...

Embodiment 2

[0042] Embodiment 2 of the present invention: the difference from Embodiment 1 is that the left side alignment mechanism 5 and the right side alignment mechanism 6 do not work synchronously. Since the distance between the suction units 5521 of the material picking part 55 can be controlled by moving the positioning assembly 551, Therefore, when slides of two different sizes need to be placed on the empty tray, the arrangement mechanism 5 on the left side controls the suction assembly 552 by moving the positioning assembly 551 to complete the arrangement and placement of the slides with small sizes. The right side alignment mechanism 6 controls the suction assembly 552 by moving the positioning assembly 551 to complete the arranging action of the slides with large specifications and sizes.

[0043] The working principle of the present invention is as follows: place the empty tray for placing glass slides on the conveying platform 71, and the moving slider of the magnetically cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com