High-development karst area superfine hole pile construction method

A construction method and karst technology, applied in the direction of sheet pile wall, foundation structure engineering, foundation structure test, etc., can solve the problems of construction period, uncontrollable cost, uncontrollable backfill quantity, occurrence of engineering accidents, etc., and achieve convenient and fast quality , The effect of small environmental factors and tight construction schedule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

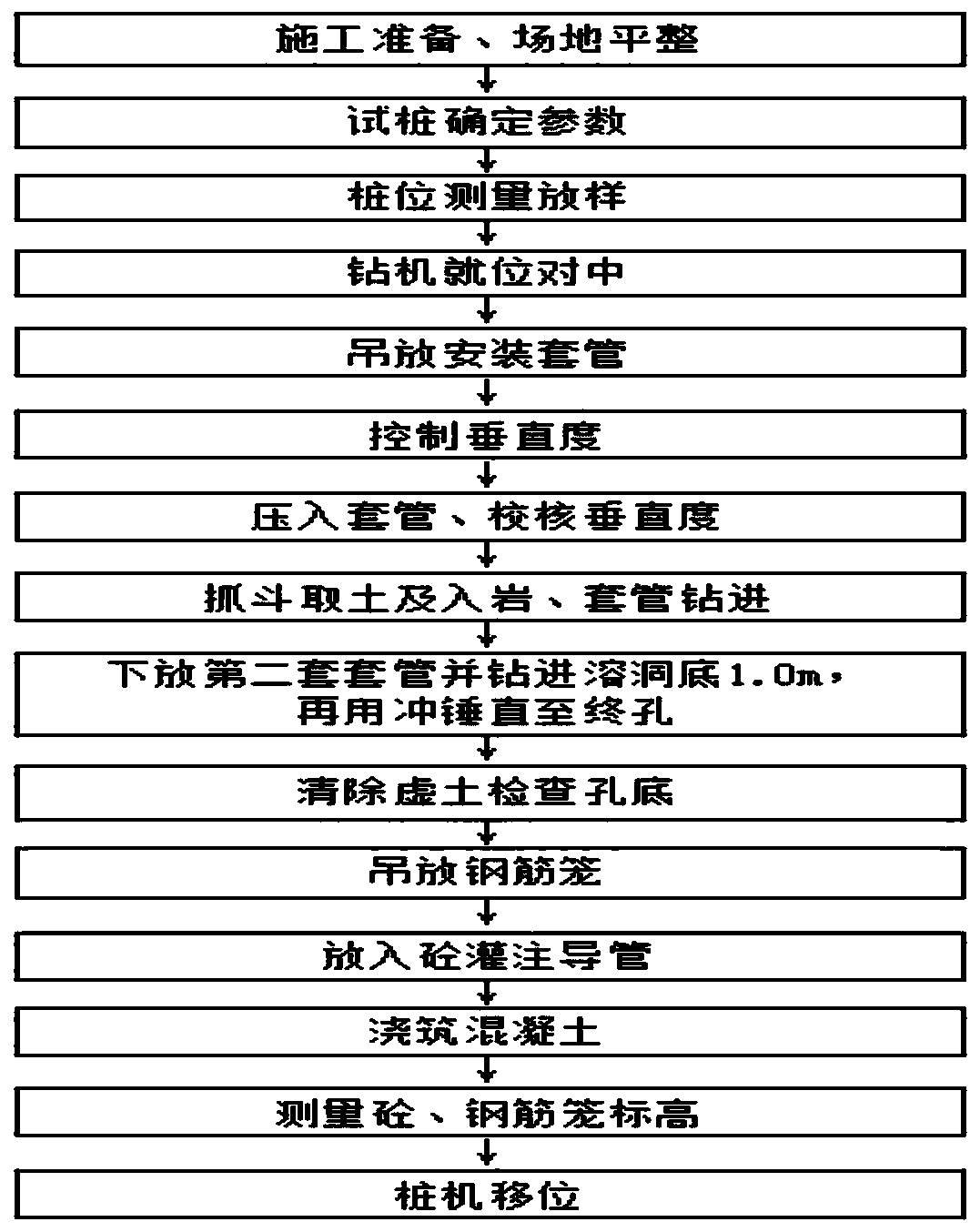

[0030] refer to figure 1 , this embodiment provides a construction method for ultra-fine hole piles in strongly developed karst areas.

[0031] 1. Preparation

[0032] 1. Before construction, the design drawings should be carefully reviewed and the site surveyed, and the construction sequence should be planned in advance according to the layout of the pile foundation.

[0033] 2. In order to ensure the bearing capacity of the engineering piles under the station floor, advanced drilling (one hole for one pile) shall be carried out for the engineering piles under the floor; the drilling depth of the advanced drilling shall not be less than 5 times the design diameter of the pile body below the pile bottom elevation; When karst caves are encountered within the design diameter range of 5 times the design pile body at an elevation, continue to drill down to keep the pile body located in the weathered rock stratum within 5 times the design diameter of the pile body.

[0034] 3. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com